Method for recovering sodium chloride from glyphosate mother liquid

A technology of glyphosate mother liquor and sodium chloride, which is applied in the field of sodium chloride recovery, can solve the problems of no treatment method, limited application prospects, pollution, etc., and achieve the effects of solving difficult processing problems, broad promotion prospects, and cheap and easy-to-get heat sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

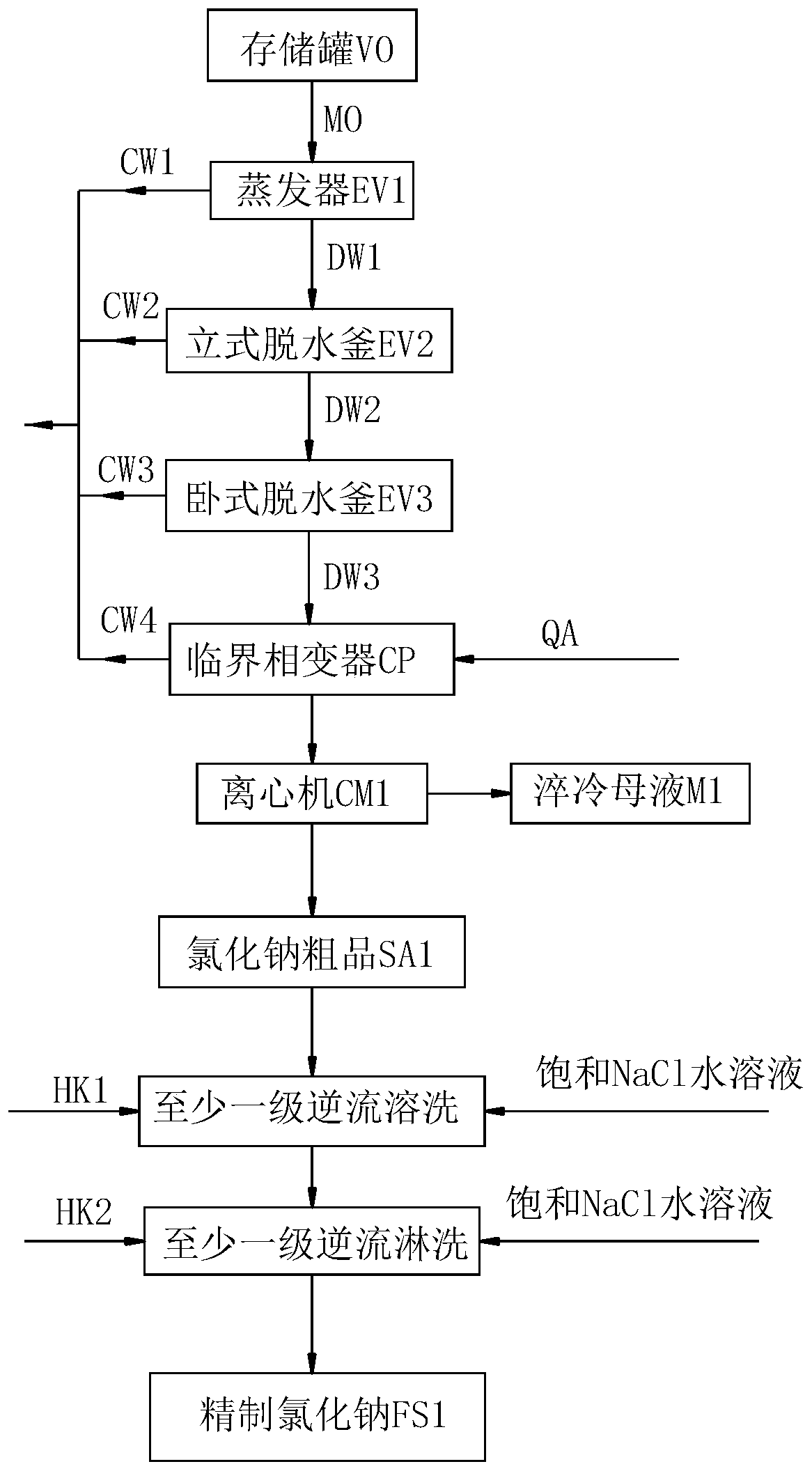

[0083] like figure 1 Shown, pump 5m from storage tank VO 3 Glycine dimethyl phosphite method produces glyphosate, the mother liquor after recovering triethylamine is used as raw material liquid MO, pH is 10, and added to evaporator EV1, evaporator EV1 is a four-effect continuous evaporator, one to four effects are evaporated and heated The room temperature is controlled at 120°C, 105°C, 90°C, 75°C, the temperature of the circulating cooling water is 25°C, and the vacuum degree is 20KPa to obtain 2.25m 3 First grade concentrate DW1 and 2.75m 3The primary condensed water CW1; the primary concentrated liquid DW1 is pumped into the vertical dehydration kettle EV2 with a stirring and coil heater, and the dehydration is continued at a stirring speed of 40 rpm, a temperature of 60°C, and a vacuum of 20KPa to obtain 2.0m 3 Secondary concentrate DW2 and 0.25 m 3 The secondary condensed water CW2; the secondary concentrated liquid DW2 is pumped into the horizontal dehydration kettle...

Embodiment 2

[0086] like figure 1 Shown, pump 5m from storage tank VO 3 Glycine dimethyl phosphite method produces glyphosate, the mother liquor after recovering triethylamine is used as raw material liquid MO, pH is 10, and added to evaporator EV1, evaporator EV1 is a four-effect continuous evaporator, one to four effects are evaporated and heated The chamber temperature is controlled at 120°C, 105°C, 90°C, and 75°C, the temperature of the circulating cooling water is 25°C, and the vacuum degree is 20KPa to obtain 2.26m 3 First grade concentrate DW1 and 2.76m 3 The primary condensed water CW1; the primary concentrated liquid DW1 is pumped into the vertical dehydration kettle EV2 with a stirring and coil heater, and the dehydration is continued at a stirring speed of 40 rpm, a temperature of 60°C, and a vacuum of 20KPa to obtain 2.0m 3 Secondary concentrate DW2 and 0.25 m 3 The secondary condensed water CW2; the secondary concentrated liquid DW2 is pumped into the horizontal dehydratio...

Embodiment 3

[0089] like figure 1 Shown, pump 5m from storage tank VO 3 Glycine dimethyl phosphite method produces glyphosate, the mother liquor after recovering triethylamine is used as raw material liquid MO, pH is 10, and added to evaporator EV1, evaporator EV1 is a four-effect continuous evaporator, one to four effects are evaporated and heated The temperature of the chamber is controlled at 110°C, 95°C, 80°C, and 65°C, the temperature of the circulating cooling water is 25°C, and the vacuum is 20KPa to obtain 2.3m 3 First grade concentrate DW1 and 2.55m 3 The primary condensed water CW1; the primary concentrated liquid DW1 is pumped into the vertical dehydration kettle EV2 with a stirring and coil heater, and the dehydration is continued at a stirring speed of 40 rpm, a temperature of 60°C, and a vacuum of 20KPa to obtain 2.2m 3 Secondary concentrate DW2 and 0.22 m 3 The secondary condensed water CW2; the secondary concentrated liquid DW2 is pumped into the horizontal dehydration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com