Zinc glycinate complex without introducing impurity ions as well as preparation method thereof

A technology of zinc glycinate and impurity ions is applied in the field of preparation of zinc glycinate complex, which can solve the problems of sewage discharge, environmental pollution, high content of COD and BOD, and achieve the effects of improving product yield and reducing production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

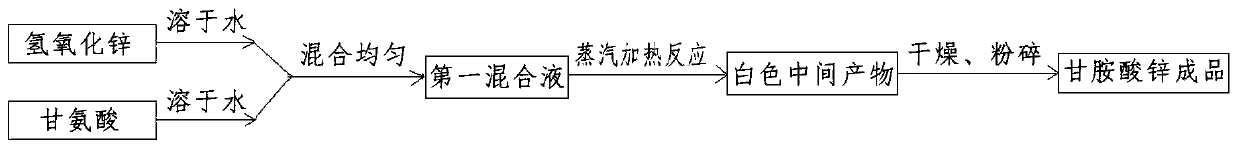

Method used

Image

Examples

Embodiment 1

[0030] This embodiment provides a kind of preparation method that does not introduce the zinc glycine complex of impurity ion, comprises the following steps:

[0031] Take 540kg of glycine and dissolve it in 2000L of water, slowly heat it to 60°C to prepare a glycine aqueous solution with a concentration of 27wt%; take 356.4Kg of zinc hydroxide and pour it into 2000L of water, stir to prepare a zinc hydroxide suspension with a concentration of 17.8wt% solution, the molar ratio of glycine and zinc hydroxide is 2:1. Pump it into the supergravity reactor with a flow rate of 1:1 through a centrifugal pump, mix it well, and then flow it into a Tangci reactor, heat it indirectly to 60°C with water vapor, react at a constant temperature for 1 hour, and pass through the resistant reactor while it is hot. The corroded mortar pump is pumped into the plate and frame filter, and enters the solid-liquid separation. The obtained filter cake is sent to the rotary rotary kiln, dried at 70°C, ...

Embodiment 2

[0038] This embodiment provides a kind of preparation method that does not introduce the zinc glycine complex of impurity ion, comprises the following steps:

[0039] Dissolve 300kg of glycine in 1000L of water, slowly heat to 60°C to prepare a 30wt% glycine aqueous solution; pour 158Kg of zinc hydroxide into 1584L of water, stir to prepare a 10wt% concentration of zinc hydroxide suspension, In this way, the molar ratio of glycine and zinc hydroxide is 2.5:1. Pump it into the supergravity reactor with a flow rate of 1:1 through a centrifugal pump, mix it well, flow it into a Tangci reactor, heat it indirectly to 50°C with steam, react at a constant temperature for 1.5 hours, and pass the corrosion resistance while it is hot The mortar pump is pumped into the centrifugal filter to enter the solid-liquid separation, and the obtained filter cake is sent to the rotary rotary kiln, dried at 80°C, crushed to 200 mesh, and packaged to obtain the finished product of zinc glycinate. T...

Embodiment 3

[0043] This embodiment provides a kind of preparation method that does not introduce the zinc glycine complex of impurity ion, comprises the following steps:

[0044] Dissolve 400kg of glycine in 2000L of water, slowly heat to 60°C to prepare a 20wt% concentration of glycine aqueous solution; pour 264Kg of zinc hydroxide into 2000L of water and stir to prepare a 13.2wt% concentration of zinc hydroxide suspension Liquid, so that the molar ratio of glycine and zinc hydroxide is 2:1. It is pumped into the supergravity reactor by a centrifugal pump according to the ratio of flow rate of 1:1, fully mixed, flowed into the Tangci reactor, indirectly heated to 65°C by steam, reacted at constant temperature for 1.2 hours, and passed the corrosion resistance while it is hot. The mortar pump is pumped into the plate and frame filter and enters the solid-liquid separation. The obtained filter cake is sent to the rotary rotary kiln, dried at 75°C, crushed to 200 mesh, and packaged to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com