Water-resistant preservative composite paper and preparation method thereof

A technology of composite paper and base paper, which is applied in pulp beating/refining methods, paper, papermaking, etc., can solve the problems of poor water resistance of fresh-keeping paper, loss of fresh-keeping effect, speed up fruits and vegetables, etc., and achieve long-term stability of antibacterial properties Good performance, improved percussion degree, and good fiber interweaving and bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

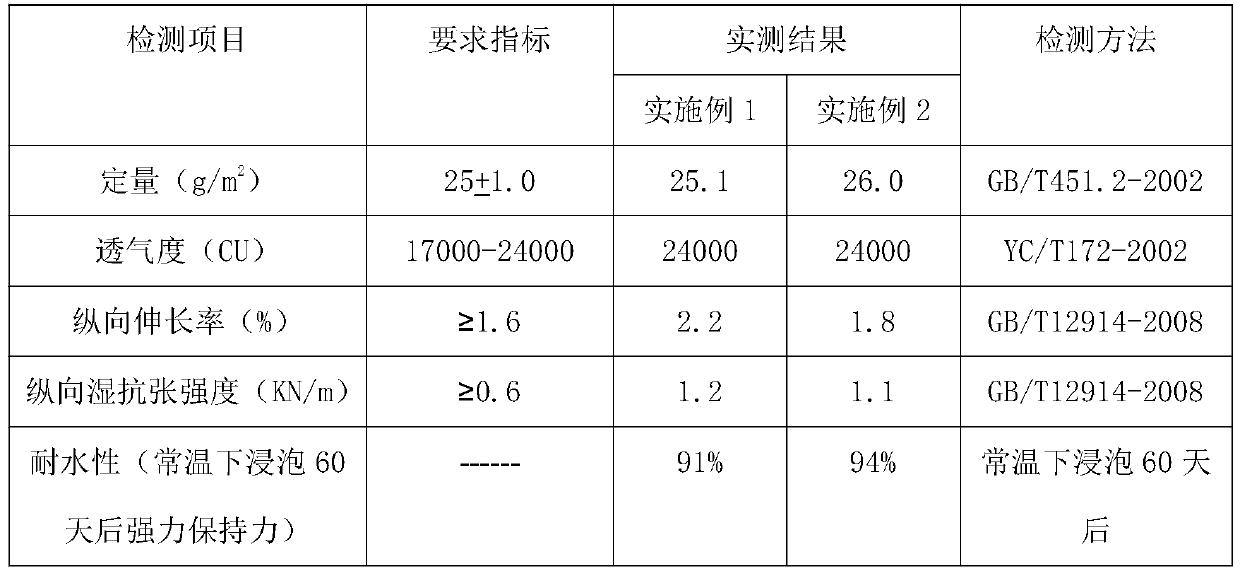

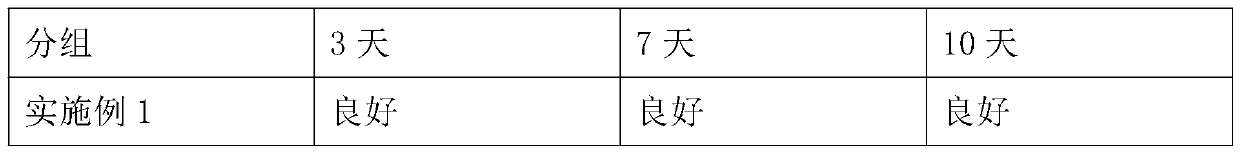

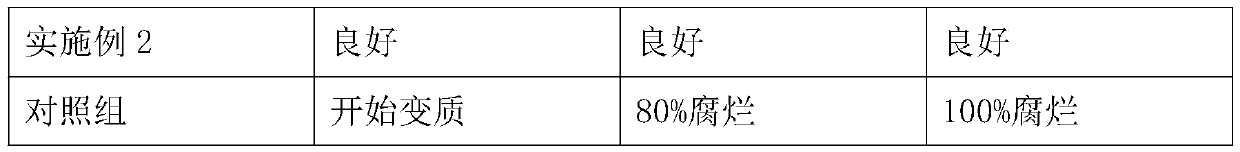

[0032] A water-resistant and fresh-keeping composite paper, comprising a base paper layer and a surface adhesive layer, wherein the base paper layer has a basis weight of 23g / m 2 , The quantitative of the surface rubber layer is 1g / m 2 ,

[0033] The base paper layer is prepared from the following components by weight of the base paper slurry, and then wet papermaking is prepared: main slurry 100, polyethylene oxide 0.2, alkyl ketene dimer 5, polyamide polyamine ring Oxychloropropane resin 15, nano-ZnO0.015, nano-TiO 2 0.016,

[0034] Among them, the main pulp is prepared by mixing bleached softwood kraft pulp, chemical fiber and water pulping. The mass concentration of bleached softwood kraft pulp in the main pulp is 5.2%. Among them, the bleached softwood kraft pulp and chemical The fiber mass ratio is 6:4;

[0035] Among them, the surface glue layer is prepared from the following components by weight of the surface glue liquid, and then prepared by the surface glue machine: polyv...

Embodiment 2

[0046] A water-resistant and fresh-keeping composite paper, comprising a base paper layer, a surface rubber layer and a natural antibacterial agent layer coated on the surface of the surface rubber layer, characterized in that the base paper layer has a basis weight of 23 g / m 2 , The quantitative of the surface rubber layer is 1g / m 2 , The quantitative of the natural antibacterial agent layer is 1g / m 2 ,

[0047] Among them, the base paper layer is prepared by wet papermaking of base paper slurry prepared from the following components by weight: total slurry 100, polyethylene oxide 0.22, alkyl ketene dimer 6, polyamide Polyamine epichlorohydrin resin 16, nano-ZnO0.02, nano-TiO 2 0.01,

[0048] The total pulp is a suspension prepared by mixing bleached softwood kraft pulp with chemical fibers and water. The mass concentration of the suspension is 5.4%. The mass ratio of the bleached softwood kraft pulp to chemical fibers is 6:4;

[0049] Among them, the surface glue layer is prepared...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com