Spherical zirconium silicate powder, preparation method and application thereof

A zirconium silicate and spherical technology, which is applied in the field of spherical zirconium silicate powder and its preparation, can solve the problems such as the inability to obtain spherical zirconium silicate, achieve good reflection effect, low thermal conductivity, good heat preservation and energy saving function. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

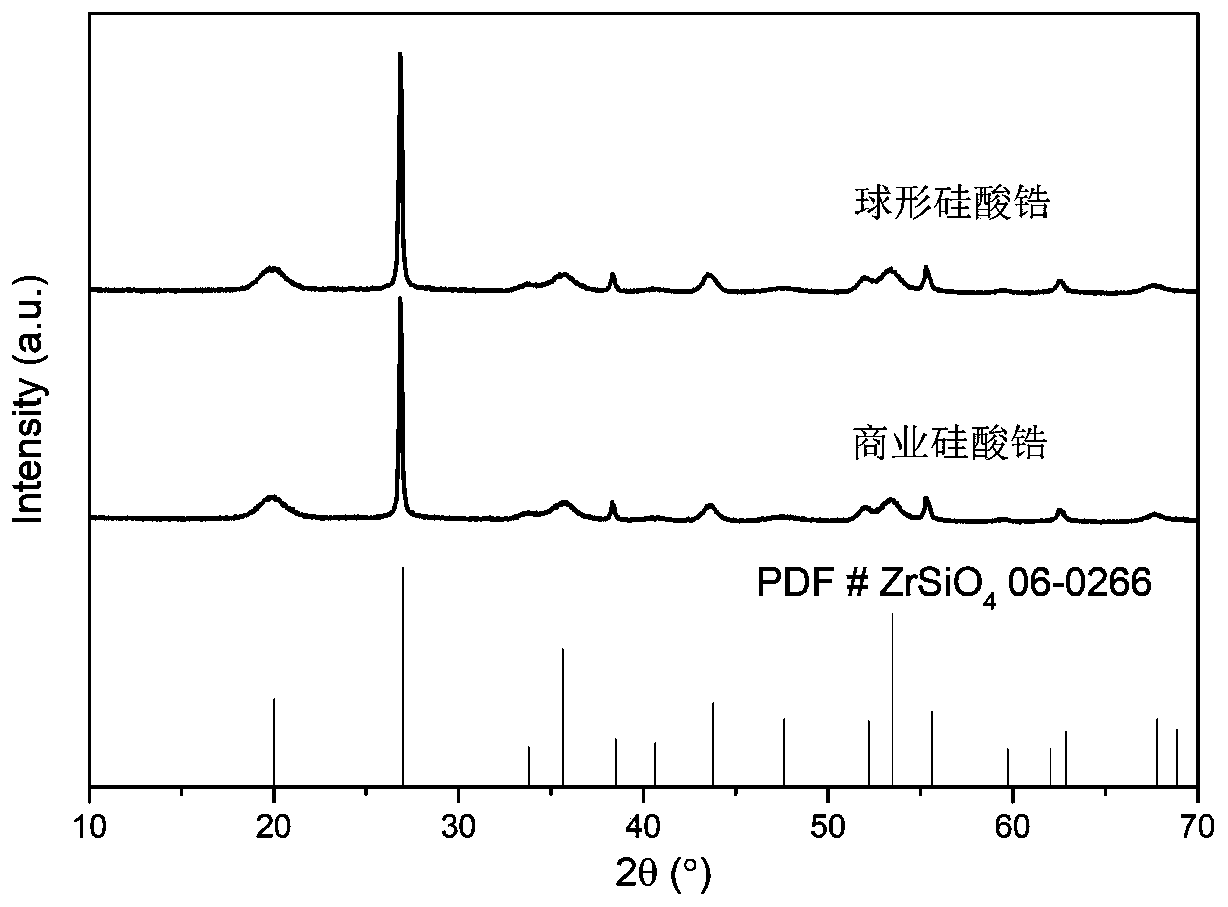

[0028] The invention provides a preparation method of spherical zirconium silicate powder, comprising the following steps:

[0029] (1) mixing zirconium source with water and acid to obtain A solution;

[0030] (2) mixing the silicon source with water and / or an organic solvent to obtain a B solution;

[0031] (3) Mix the A solution with the B solution, and obtain a reaction precursor after ultrasonication;

[0032] (4) mixing the reaction precursor solution with a surfactant and a mineralizer, and carrying out a hydrothermal reaction to obtain spherical zirconium silicate powder;

[0033] The steps (1) and (2) are not limited by time sequence.

[0034] Unless otherwise specified, the raw materials used in the present invention are all commercially available.

[0035] In the invention, the zirconium source is mixed with water and acid to obtain A solution. In the present invention, the zirconium source is preferably one or more of zirconium sulfate, zirconium nitrate, zirco...

Embodiment 1

[0053] (1) Zirconium oxychloride is mixed with water and perchloric acid to obtain A solution, wherein the molar concentration of zirconium oxychloride is 0.20mol L -1 , the mol ratio of zirconium oxychloride and perchloric acid is=1:20;

[0054] (2) Sodium silicate is mixed with water to obtain solution B, wherein the molar ratio of sodium silicate to water is 1:150;

[0055] (3) Slowly add solution B to solution A, control the molar ratio of zirconium to silicon to be 1:1, and ultrasonically obtain the reaction precursor;

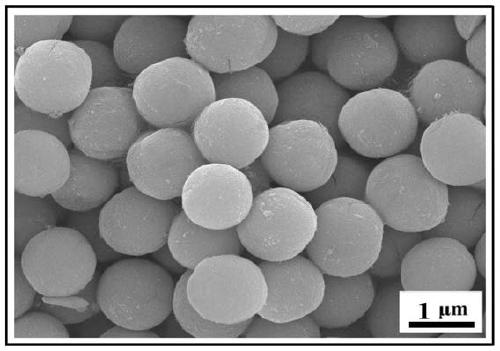

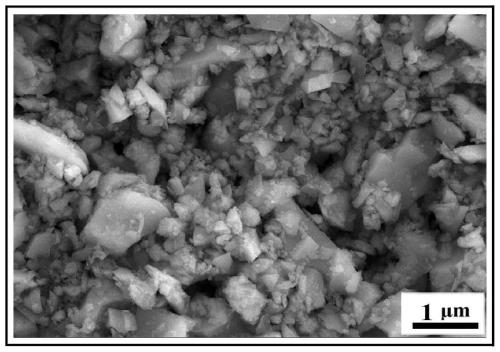

[0056] (4) Add sodium fluoride (the molar ratio of zirconium oxychloride to sodium fluoride is 1:0.2) and PVP (the addition amount is 5% of the total mass of the theoretical product) in the reaction precursor solution, and put it into the reaction kettle Hydrothermal reaction at 180°C for 12 hours, the filling degree of the reactor was maintained at 60%, centrifuged, washed and dried to obtain spherical zirconium silicate powder;

[0057] The steps (1) ...

Embodiment 2

[0065] 10g of spherical zirconium silicate powder prepared in Example 1 and glaze (20% of calcite, 15% of albite feldspar, 15% of potassium feldspar, 30% of calcined kaolin, 10% of barium carbonate, 10% of frit) 20g and Mix 100g of water evenly, apply it on a 2×2cm ceramic green body by spin coating (speed 600r / min, t=5min), and fire at 800°C for 20min to obtain a ceramic heat shielding material based on spherical zirconium silicate powder .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com