Method for degrading polycyclic aromatic hydrocarbon wastewater based on layered titanium lanthanum niobate as catalyst

A polycyclic aromatic hydrocarbon and catalyst technology, which is applied in the fields of industrial catalysis and ecological environment protection, can solve the problems of easy agglomeration of particles and weak adsorption of organic substances, and achieves the effects of high degree of reaction, high dispersibility, and reduced use cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

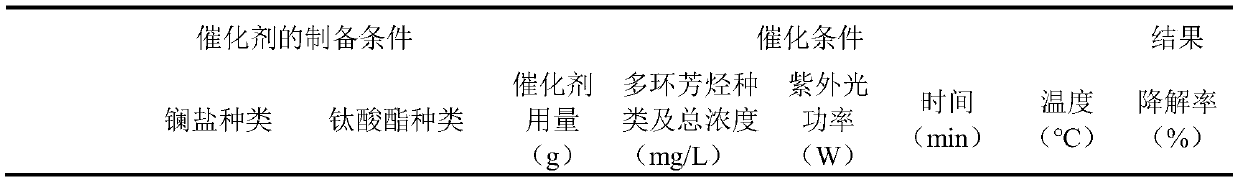

Embodiment 1

[0025] A method for degrading polycyclic aromatic hydrocarbon wastewater based on layered lanthanum niobate-titanium catalyst, comprising the following steps:

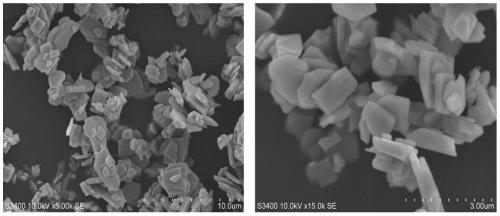

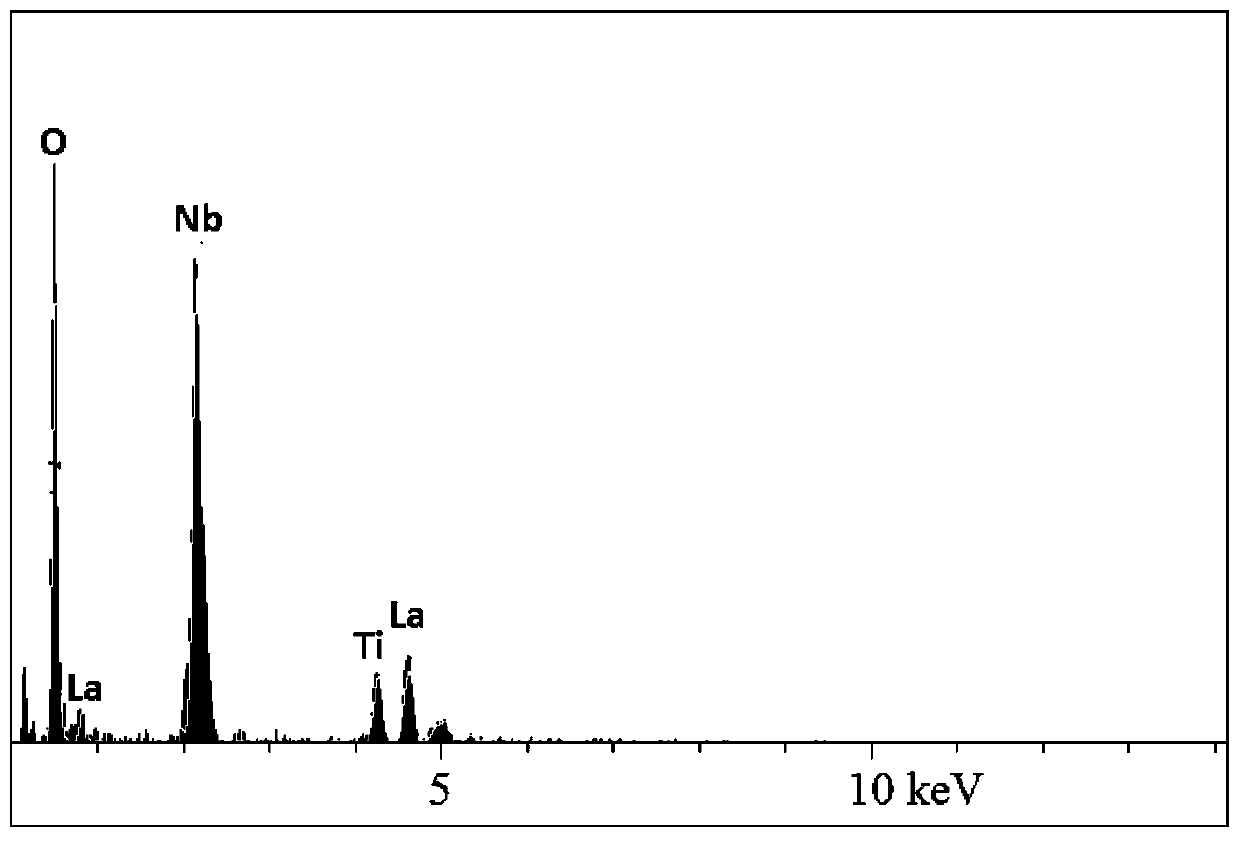

[0026] (1) Disperse 0.005mol of lanthanum carbonate, 0.01mol of niobium hydroxide and 0.005mol of tetra-n-butyl titanate in 100mL of absolute ethanol at a stirring speed of 1200r / min, and slowly add 120mL of Deionized water, continue to stir and react for 240 minutes to fully hydrolyze the titanate, put it in an oven and dry it at 105°C for 10 hours to obtain the catalyst precursor;

[0027] (2) Press the above catalyst precursor into a cylindrical shape under the pressure of 30MPa, put it into a vacuum ceramic tube furnace, and raise the temperature to 1050°C at a rate of 5°C / min in the air atmosphere and keep it warm for 180min, then cool After grinding and crushing, the layered titanium lanthanum niobate catalyst is obtained;

[0028] (3) Add 0.01g of layered titanium lanthanum niobate to 150mL of naphthalene-conta...

Embodiment 2

[0030] A method for degrading polycyclic aromatic hydrocarbon wastewater based on layered lanthanum niobate-titanium catalyst, comprising the following steps:

[0031] (1) Disperse 0.005mol of lanthanum carbonate, 0.01mol of niobium hydroxide and 0.005mol of isopropyl titanate in 100mL of absolute ethanol at a stirring speed of 1200r / min. After heating up to 60°C, slowly drop 120mL to remove Ionized water, continue to stir and react for 240 minutes to fully hydrolyze the titanate, put it in an oven and dry it at 105°C for 10 hours to obtain the catalyst precursor;

[0032] (2) Press the above catalyst precursor into a cylindrical shape under the pressure of 30MPa, put it into a vacuum ceramic tube furnace, and raise the temperature to 1050°C at a rate of 5°C / min in the air atmosphere and keep it warm for 180min, then cool After grinding and crushing, the layered titanium lanthanum niobate catalyst is obtained;

[0033](3) Add 0.02g of layered titanium lanthanum niobate to 150...

Embodiment 3

[0035] A method for degrading polycyclic aromatic hydrocarbon wastewater based on layered lanthanum niobate-titanium catalyst, comprising the following steps:

[0036] (1) Disperse 0.005mol lanthanum hydroxide, 0.01mol niobium hydroxide and 0.005mol tetra-n-butyl titanate in 100mL absolute ethanol at a stirring speed of 1200r / min, raise the temperature to 60°C, and slowly add 120mL of deionized water, continue stirring for 240min to fully hydrolyze the titanate, put it in an oven at 105°C and dry for 10h to obtain the catalyst precursor;

[0037] (2) Press the above catalyst precursor into a cylindrical shape under the pressure of 30MPa, put it into a vacuum ceramic tube furnace, and raise the temperature to 1050°C at a rate of 5°C / min in the air atmosphere and keep it warm for 180min, then cool After grinding and crushing, the layered titanium lanthanum niobate catalyst is obtained;

[0038] (3) Add 0.05g of layered titanium lanthanum niobate to 150mL of acenaphthylenene-con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com