Metformin-pioglitazone salt, and preparation method and application thereof

A technology of pioglitazone salt and metformin, which is applied in its preparation method and its pharmaceutical composition, metformin-pioglitazone crystal salt field, can solve the problem of poor pharmaceutical properties, low solubility, increased glucose oxidation and adipose tissue in skeletal muscle and adipose tissue Metabolism and other problems, to achieve the effects of easy control of the crystallization process, improved moisture absorption stability, and improved solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

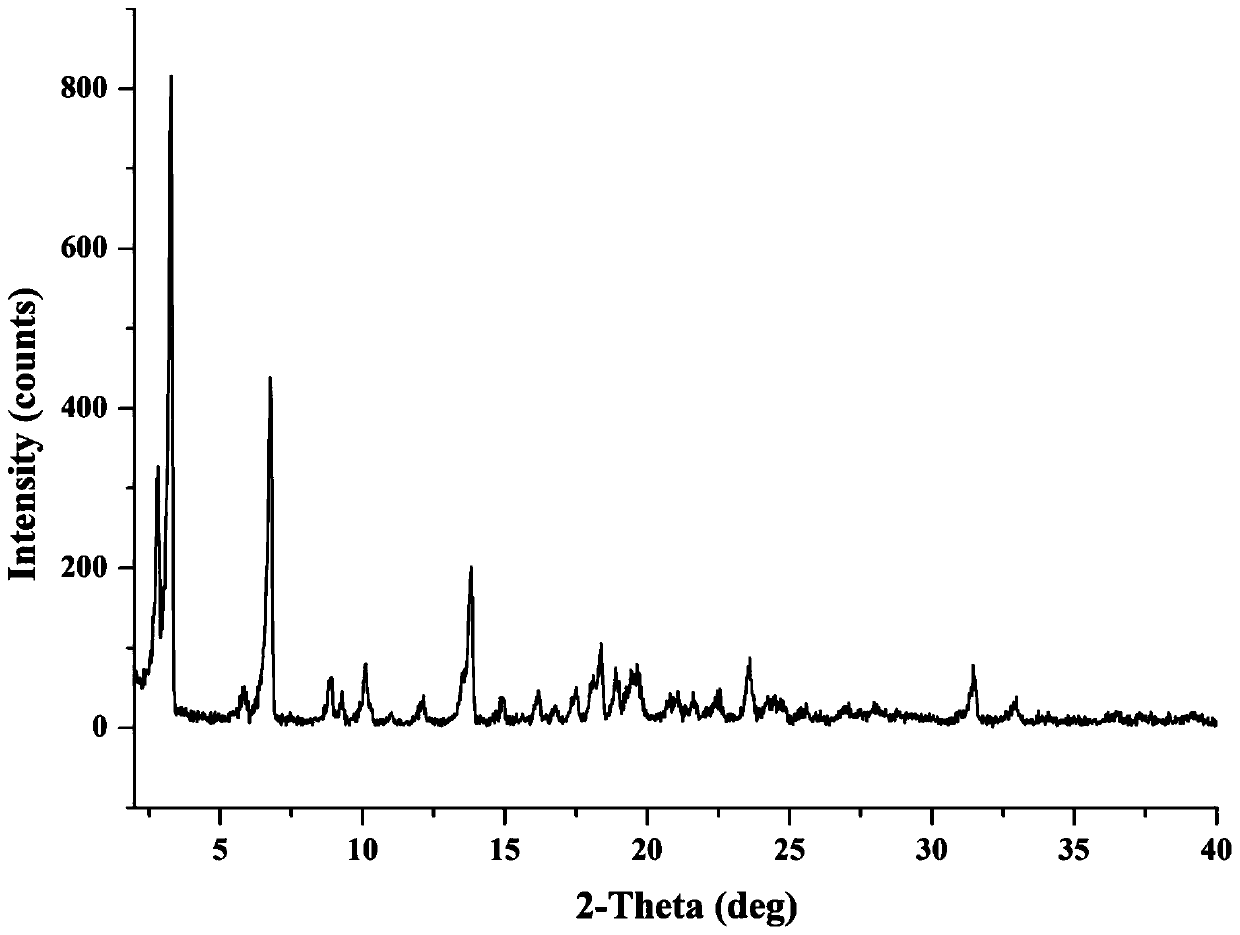

[0037] Take 28.5mg of pioglitazone and 10.8mg of metformin (molar ratio is 1:1) and put them in a 4mL sample bottle, add 2mL of acetonitrile, sonicate, make it dissolve and be in a supersaturated state, react and crystallize at room temperature for 24 hours, and dissolve the suspension Centrifuge, discard the supernatant, and dry the centrifuged solid in a blast oven at 40°C for 3 hours to obtain metformin-pioglitazone salt. The XRPD results are as follows: figure 1 .

Embodiment 2

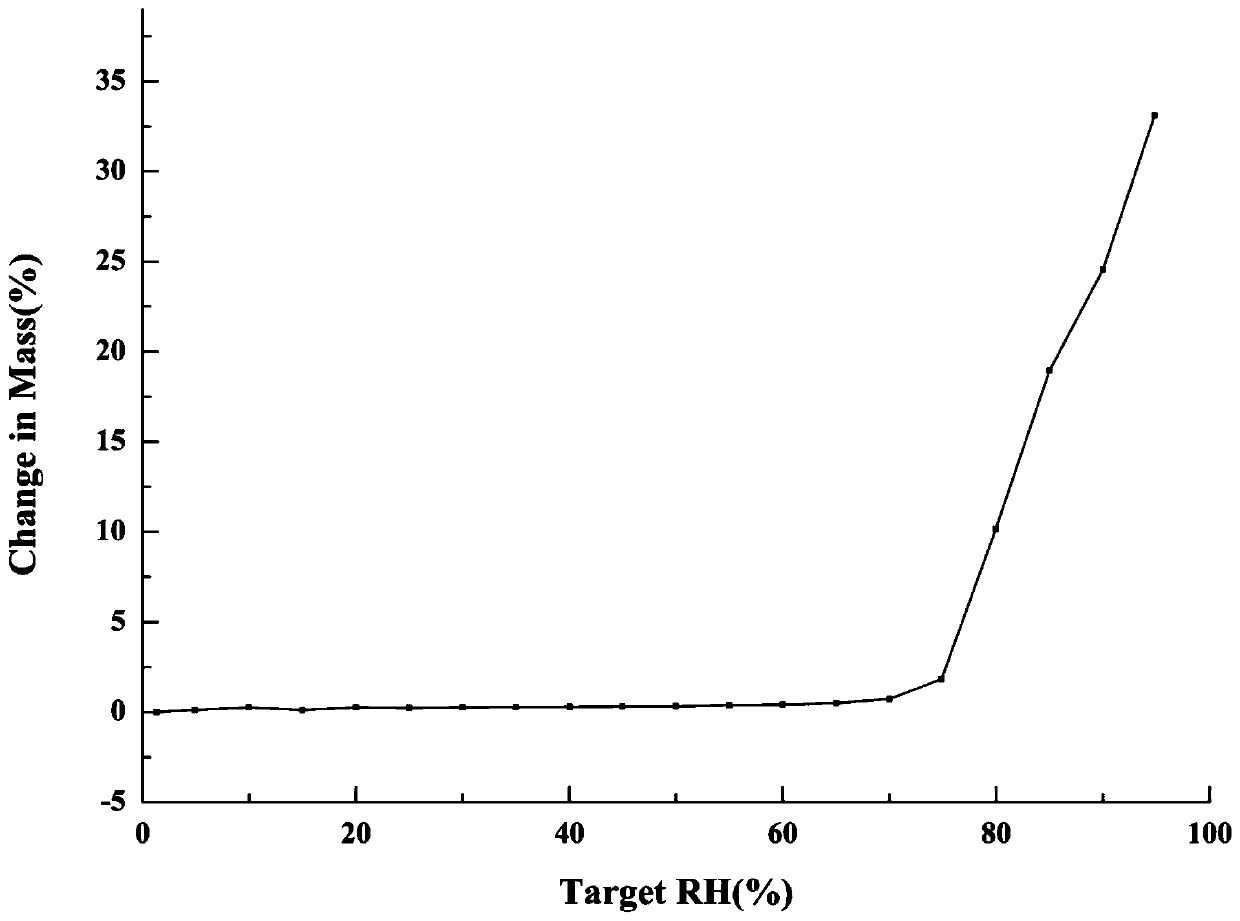

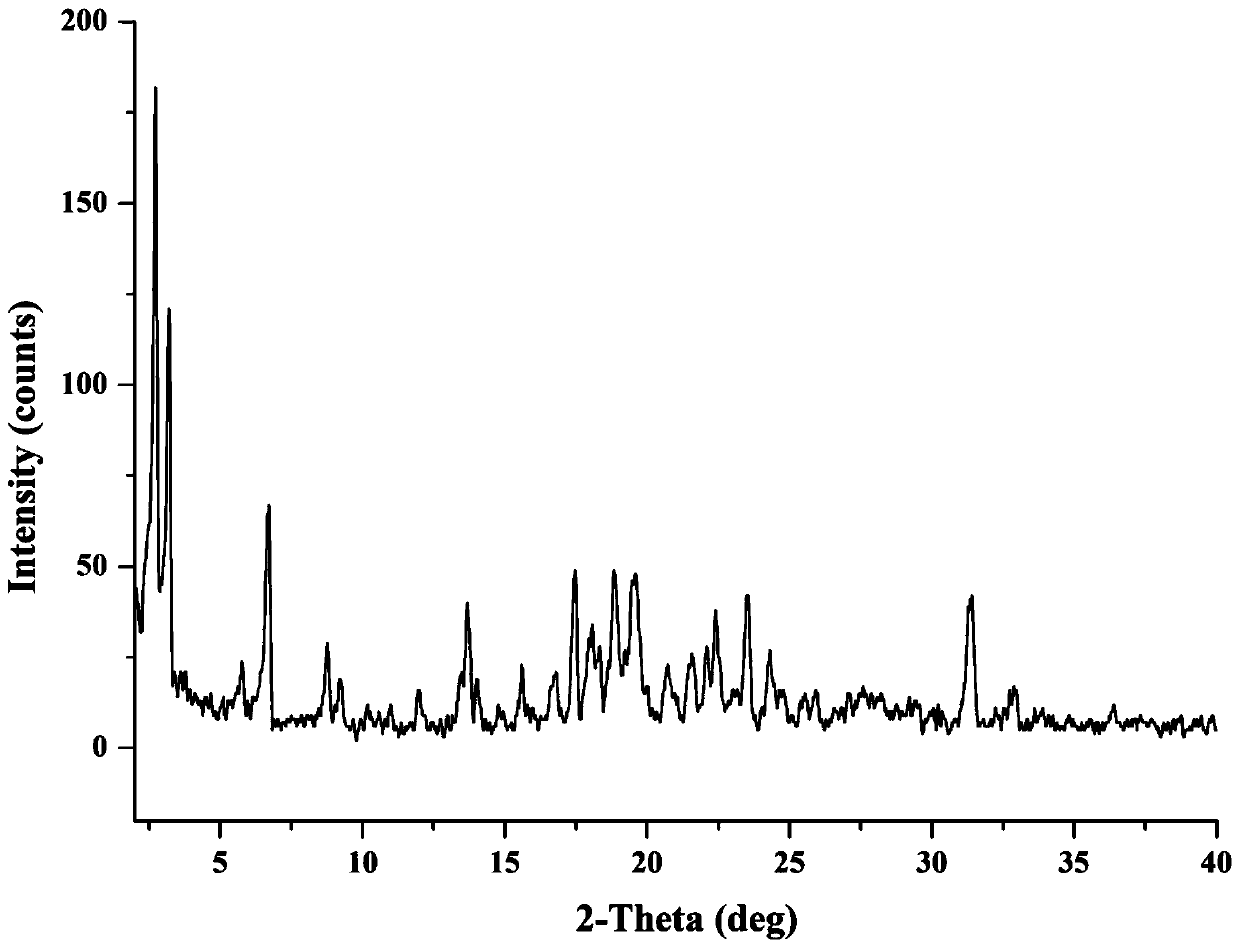

[0039] Get about 3 mg of the solid sample of metformin-pioglitazone salt prepared in Example 1 and carry out dynamic moisture adsorption analysis. +Determination by dynamic moisture adsorption instrument. The temperature is 25°C and the relative humidity range is 1-95%. The results showed that when the relative humidity was from 1% to 70% relative humidity, the mass percentage of the water content of the salt did not increase significantly. When reaching 95% relative humidity, the mass fraction percentage of the water content of the salt increases to 33%, as figure 2 . And the salt remains unchanged, the XRPD pattern after DVS is as follows image 3 . And the known metformin prototype drug draws humidity to increase obviously when reaching 95% relative humidity, has been as high as 86%. As attached to the manual Figure 4 .

Embodiment 3

[0041] Take 28.5mg of pioglitazone and 9.6mg of metformin (molar ratio is 1:0.92) into a 4mL sample bottle, add 2mL of isopropyl acetate, sonicate to dissolve and become supersaturated, react and crystallize at 50°C for 12 hours, Centrifuge the suspension, discard the supernatant, and dry the centrifuged solid in a blast oven at 60°C for 1 hour to obtain metformin-pioglitazone salt. The XRPD results are as follows: Figure 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com