Radial fixed-bed dehydration reactor

A radial fixed bed and reactor technology, applied in chemical instruments and methods, hydrocarbon production from oxygen-containing organic compounds, organic chemistry, etc., can solve problems affecting reactor uniformity, blockage of distribution holes, long process, etc., to achieve Effects of avoiding thermal decomposition, reducing olefin polymerization, and improving device yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

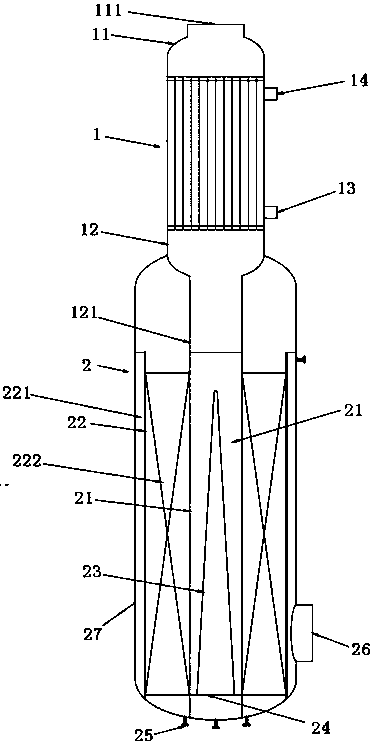

[0040] Embodiment one, such as figure 1 Shown: the present invention relates to a radial fixed-bed dehydration reactor, comprising an inlet heating section 1 and a radial reaction section 2 .

[0041] Such as figure 1 As shown: the air inlet heating section 1 adopts a shell-and-tube heat exchanger, which is provided with an upper head 11 and a lower head 12, the upper head 11 is provided with a tube-side air inlet 111 of the air inlet heating section, and the lower head 12 is provided with a pipe side air outlet 121; the shell side of the intake heating section is provided with a heat medium inlet 13 and a heat medium outlet 14. The pipe-side air outlet 121 of the inlet heating section is connected with the air inlet of the radial reaction section, that is, the air inlet of the central air distribution pipe 21 .

[0042] In the present invention, the inlet heating section 1 and the radial reaction section 2 can be integrated and compactly arranged, and of course they can als...

Embodiment 2

[0047] Embodiment two, such as figure 2 Shown: In this embodiment, on the basis of Embodiment 1, an axial reaction section 3 is added, and the axial reaction section 3 is located between the inlet heating section 1 and the radial reaction section 2; the axial reaction section 3 includes the The head 31, the axial catalytic bed layer 32 and the axial lower head 33, the axial upper head 31 is provided with a feed port correspondingly connected with the lower head tube side gas outlet 121 of the inlet heating section; the axial lower seal The head 33 is provided with a discharge port 331 connected to the air inlet of the central gas distribution pipe 21 , and the shell at the inlet end of the radial reaction section 2 is connected to the axially lower head 33 by welding.

[0048] In this embodiment, the distance between the upper layer of the axial catalytic bed layer and the upper axial head is 2m, and the distance between the lower layer of the axial catalytic bed layer and th...

Embodiment 3

[0054] Embodiment three, such as image 3 Shown: In this embodiment, the reactor described in Example 2 is used to form the first dehydration reactor, and the reactor described in Example 1 is used to form the second dehydration reactor, and the two form a joint production.

[0055] The above-mentioned equipment is applied to the 200,000 tons / year propylene oxide co-production 450,000 tons / year styrene plant, and the oxidation reactor for dehydrating phenylethanol to styrene. The specific dimensions are shown in Table 2.

[0056] Table 2 Main dimensions of the two reactors in Example 3

[0057] project Dimensions, mm Number of units 2 units diameter D 3600 Height (cylinder) H 18050 / 13700 Reaction basket diameter do 3100 Distributor diameter di 1000 Diversion cone and base angle α 86 °

[0058] The flow process of this embodiment is that the phenylethanol raw material enters the vaporizer to be vaporized, and then enters the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com