Heat preservation food packaging box and preparation method thereof

A technology for food packaging boxes and outer boxes, applied in the directions of lining/internal coating, covering/external coating, etc., can solve the problems of increasing system cost, limitation of application scope, etc., and achieve the effect of good thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

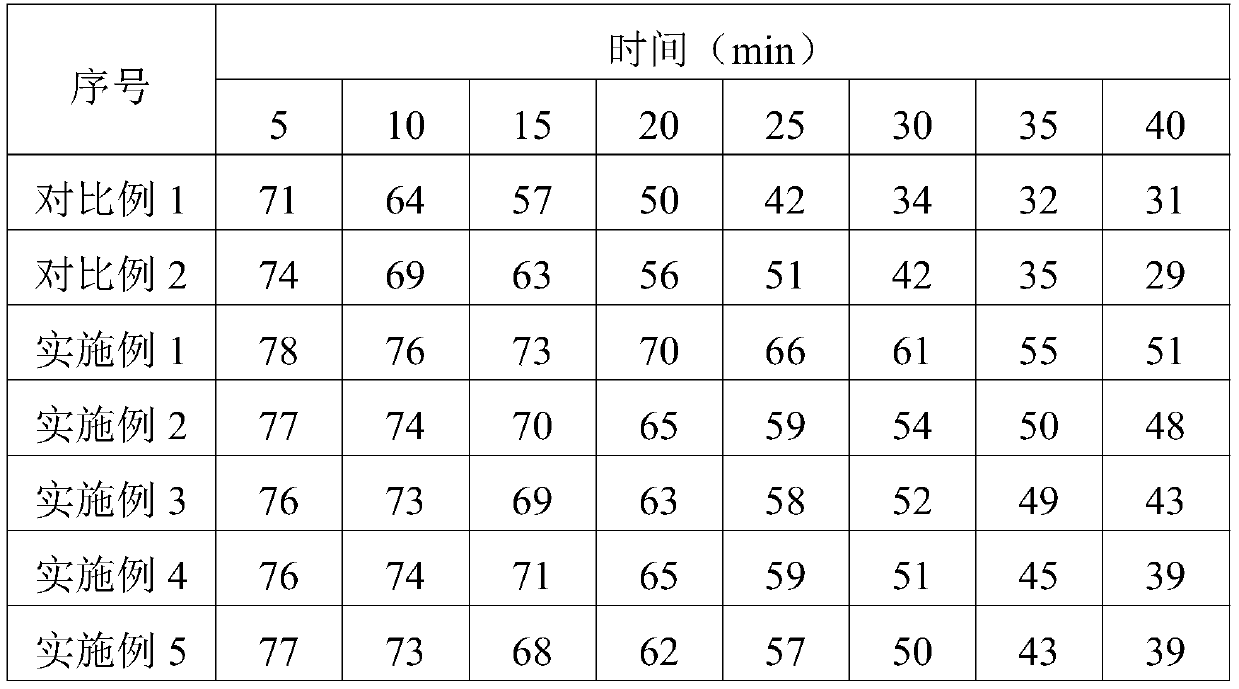

Examples

Embodiment 1

[0075] Insulated food packaging box, including outer box and inner liner. The inner wall of the outer box contains the coating of phase-change material, the shape of the outer box is consistent with that of the inner bag, and the size of the inner bag is slightly smaller than that of the outer box, so that the inner bag can be embedded in the outer box.

[0076] The phase change material is composed of neopentyl glycol and pentaerythritol; the mass ratio of neopentyl glycol and pentaerythritol is 3:2.

[0077] The material of the outer box is heat-insulating polypropylene, wherein the raw material ratio of the heat-insulating polypropylene is: expanded perlite 8wt%, dispersant 1.5wt%, polypropylene 90.5%, and the dispersant is composed of calcium stearate , polyethylene wax mixed composition; the mass ratio of calcium stearate, polyethylene wax is 1:1.

[0078] The material of the liner is biaxially stretched polystyrene, wherein the raw material ratio of the biaxially stretc...

Embodiment 2

[0089] Basically the same as Example 1, the only difference is:

[0090] The material of the outer box is heat-insulating polypropylene, wherein the raw material ratio of the heat-insulating polypropylene is: expanded perlite 7wt%, dispersant 1.5wt%, polypropylene 91.5%, and the dispersant is composed of calcium stearate and polyethylene wax; the mass ratio of the calcium stearate and the polyethylene wax is 1:1.

[0091] In Example 2, the thermal insulation performance of the outer box was tested with reference to GB / T 10294-2008, and the temperature of the cold plate of the thermal conductivity instrument was set to 25°C and the temperature of the hot plate was 80°C. After testing, the thermal conductivity of Example 2 was 0.035W / (m·k).

[0092] The tensile properties of the outer box in Example 2 were tested with reference to the invention of Patent Application No. 201410254036.2. Test conditions: temperature 20°C, relative humidity 50%, speed 20mm / min. After testing, th...

Embodiment 3

[0094] Basically the same as Example 1, the only difference is:

[0095] The material of the outer box is heat-insulating polypropylene, wherein the raw material ratio of the heat-insulating polypropylene is: expanded perlite 9wt%, dispersant 1.5wt%, polypropylene 89.5%, and the dispersant is composed of calcium stearate and polyethylene wax; the mass ratio of the calcium stearate and the polyethylene wax is 1:1.

[0096] In Example 3, the thermal insulation performance of the outer box was tested with reference to GB / T 10294-2008, and the temperature of the cold plate of the thermal conductivity instrument was set to 25°C and the temperature of the hot plate was 80°C. After testing, the thermal conductivity of Example 3 is 0.016W / (m·k).

[0097] The tensile properties of the outer box in Example 3 were tested with reference to the invention of Patent Application No. 201410254036.2. Test conditions: temperature 20°C, relative humidity 50%, speed 20mm / min. After testing, the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap