Preparation method for high-purity gliclazide intermediate namely p-toluenesulfonylurea

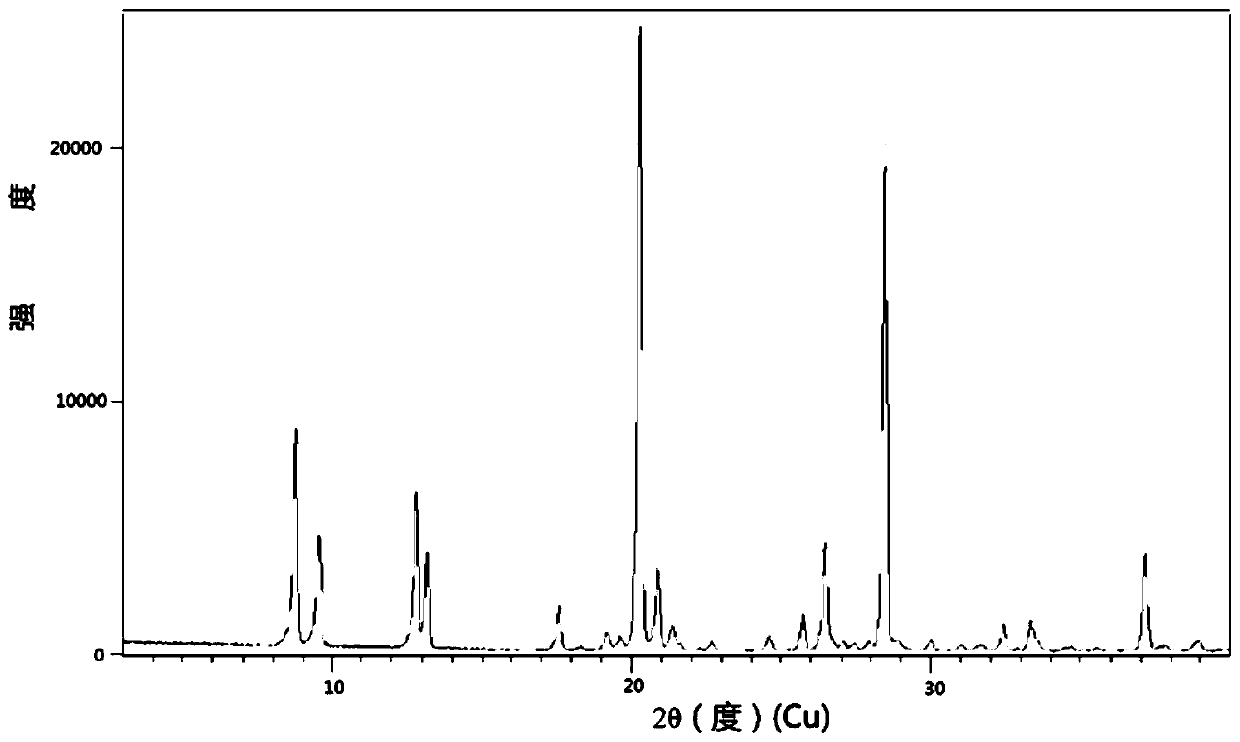

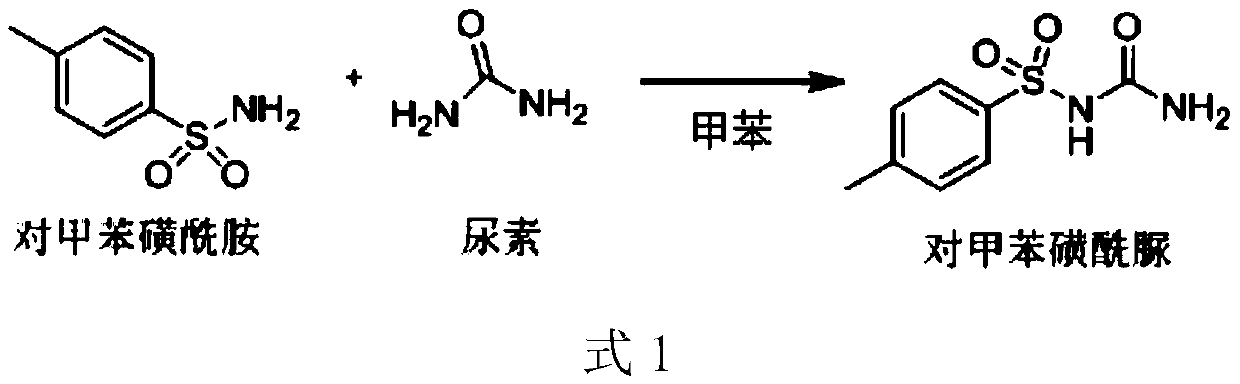

A technology for tosyl urea, crude tosyl urea, applied in the field of pharmaceutical chemical synthesis, can solve the problems of restricting the production and development of tosyl urea products, having a purity of only 98%, low product quality and the like, achieving mild conditions and easy Storage, high purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

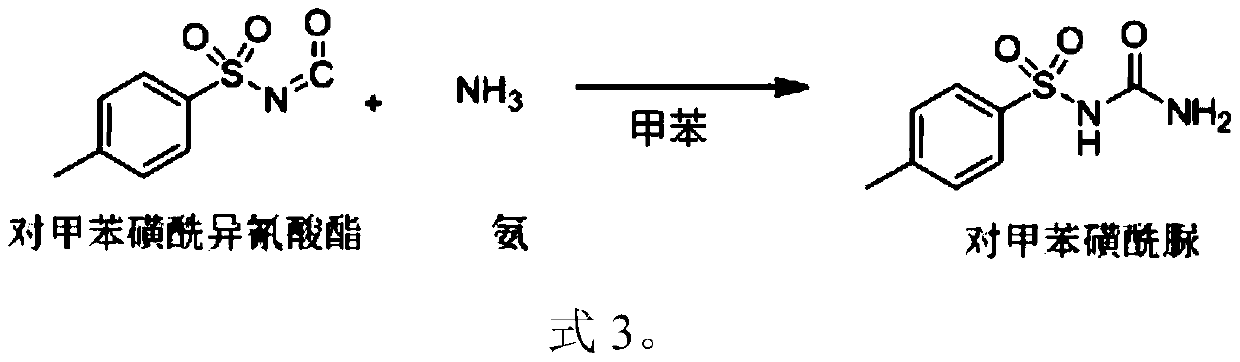

[0029] A kind of simple and convenient preparation method of p-toluenesulfonylurea, comprises the steps:

[0030] First fill the 3000L stainless steel reactor with nitrogen to replace the air in it, then add p-toluenesulfonyl isocyanate (Sinopharm Chemical Reagent Co., Ltd.) (197kg, 1000mol) and toluene (1000L), stir and cool down to -5~5℃ , slowly filled with ammonia gas (136kg, 8000mol, about 0.6MPa), white solid precipitated out after 4 hours of heat preservation reaction, slowly emptied (absorbed with 1% hydrochloric acid solution), replaced with nitrogen, stopped refrigeration, and slowly heated up to 25-30 ℃, keep warm for 4 hours, filter, wash with water until the pH is about 7, and obtain the crude product of p-toluenesulfonylurea.

[0031] Then add the crude product of p-toluenesulfonylurea into a 3000L reaction kettle, then add 2000L of acetonitrile / water (volume ratio: 1:1), heat to 80±5°C, reflux for 1h, program cooling (10°C / h), Lowered to below 20°C, centrifuged...

Embodiment 2

[0037] A kind of simple and convenient preparation method of p-toluenesulfonylurea, comprises the steps:

[0038] First fill the 3000L stainless steel reactor with nitrogen to replace the air in it, then add p-toluenesulfonyl isocyanate (Sinopharm Chemical Reagent Co., Ltd.) (200kg, 1015mol) and toluene (1015L), stir and cool down to -5~5℃ , slowly filled with ammonia gas (86.3kg, 5075mol, about 0.6MPa), white solid precipitated out after 4 hours of heat preservation reaction, slowly emptied (absorbed with 1% hydrochloric acid solution), replaced with nitrogen, stopped refrigeration, and slowly heated up to 25~ Keep warm at 30°C for 4 hours, filter, and wash with water until the pH is about 7 to obtain the crude product of p-toluenesulfonylurea.

[0039] Then add the crude p-toluenesulfonylurea into a 3000L reaction kettle, then add 2030L of acetonitrile / water (volume ratio: 1:1), heat to 80±5°C, reflux for 1h, program cooling (10°C / h), Lowered to below 20°C, centrifuged and ...

Embodiment 3

[0041] A kind of simple and convenient preparation method of p-toluenesulfonylurea, comprises the steps:

[0042] First fill the 3000L stainless steel reactor with nitrogen to replace the air in it, then add p-toluenesulfonyl isocyanate (Sinopharm Chemical Reagent Co., Ltd.) (191kg, 970mol) and toluene (970L), stir and cool down to -5~5℃ , slowly filled with ammonia gas (247kg, 14550mol, about 0.6MPa), white solid precipitated out after 4 hours of heat preservation reaction, slowly emptied (absorbed with 1% hydrochloric acid solution), replaced with nitrogen, stopped refrigeration, and slowly heated up to 25-30 ℃, keep warm for 4 hours, filter, wash with water until the pH is about 7, and obtain the crude product of p-toluenesulfonylurea.

[0043]Then add the crude p-toluenesulfonylurea into a 3000L reaction kettle, then add acetonitrile / water (volume ratio: 1:1) 1940L, heat to 80±5°C, reflux for 1h, program cooling (10°C / h), Lowered to below 20°C, centrifuged and dried to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com