A kind of ti-mn based porous hydrogen evolution cathode material, preparation method and application

A hydrogen evolution cathode and porous material technology, applied in electrodes, electrolysis components, electrolysis process, etc., can solve the problems of easy dissolution and damage of components, and achieve the effect of protecting electrode materials, reducing reaction activation energy, and reducing hydrogen evolution over-site.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Step 1: Mix titanium sponge, manganese powder, and chromium powder at a molar ratio of 1:1.8:0.3, put it into a suspension induction furnace, and repeatedly smelt it three times in a high-purity argon environment, and pour it into a water-cooled copper crucible to obtain Ti 33 mn 60 Cr 7 alloy.

[0033] Among them, the hydrogen absorption and desorption performance test of the alloy was carried out on a Sievert-type gas reaction controller, evacuated at 473K for 30 minutes, and then absorbed hydrogen at 298K and 5MPa initial hydrogen pressure for 20 minutes, and then raised the temperature to 473K and evacuated , so repeated 3 times to complete the activation process of the alloy. The alloy is tested for hydrogen absorption and desorption under the condition of 298K. Under the hydrogen pressure of 5MPa, the hydrogen absorption and absorption capacity of the alloy, and the hydrogen desorption capacity of the alloy are the difference between the hydrogen absorption capa...

Embodiment 2

[0038] Step 1: Mix titanium sponge, manganese powder, and iron filings at a molar ratio of 1.2:1.6:0.2, put them into a suspension induction furnace, and repeatedly smelt them three times in a high-purity argon environment, and pour them into a water-cooled copper crucible to obtain Ti 40 mn 53 Fe 7 alloy. The hydrogen absorption and desorption performance test of the alloy is the same as in Example 1, and the test results show that the obtained Ti 40 mn 53 Fe 7 The effective hydrogen desorption capacity of the alloy is 1.78wt%.

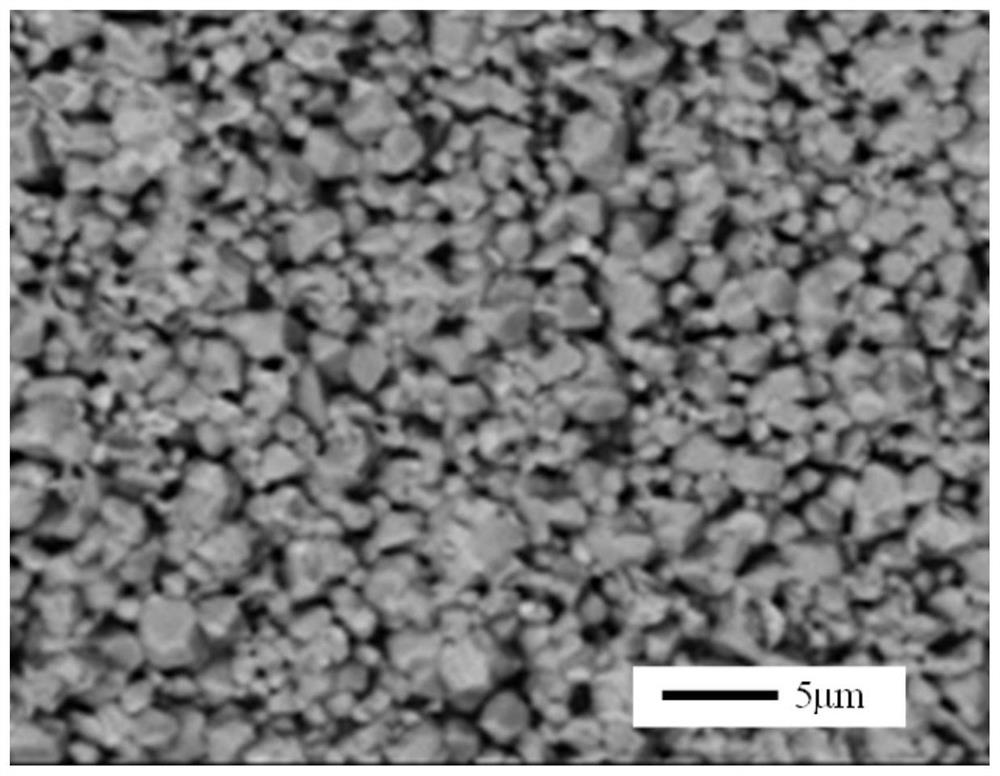

[0039] Step 2: The obtained alloy is mechanically ground into powder with a particle size of about 1-20 μm. then Ti 40 mn 53 Fe 7 The alloy powder is pressed and formed, the pressing pressure is 200MPa, the holding time is 1min, and then sintered in the argon atmosphere, the temperature is 900°C, the time is 1h, and Ti is obtained after cooling in the furnace. 40 mn 53 Fe 7 porous alloy substrate.

[0040] Step 3: Take Ti 40 mn 53 Fe 7...

Embodiment 3

[0043] Step 1: Mix titanium sponge, manganese powder, chromium powder, and iron filings at a molar ratio of 1:1.5:0.35:0.15, put it into a suspension induction furnace, and repeatedly smelt it three times in a high-purity argon environment, and place it in a water-cooled copper crucible Pouring in, get Ti 33 mn 50 Cr 12 Fe 5 alloy. The hydrogen absorption and desorption performance test of the alloy is the same as in Example 1, and the test results show that the obtained Ti 33 mn 50 Cr 12 Fe 5 The effective hydrogen release capacity of the alloy is 1.85wt%.

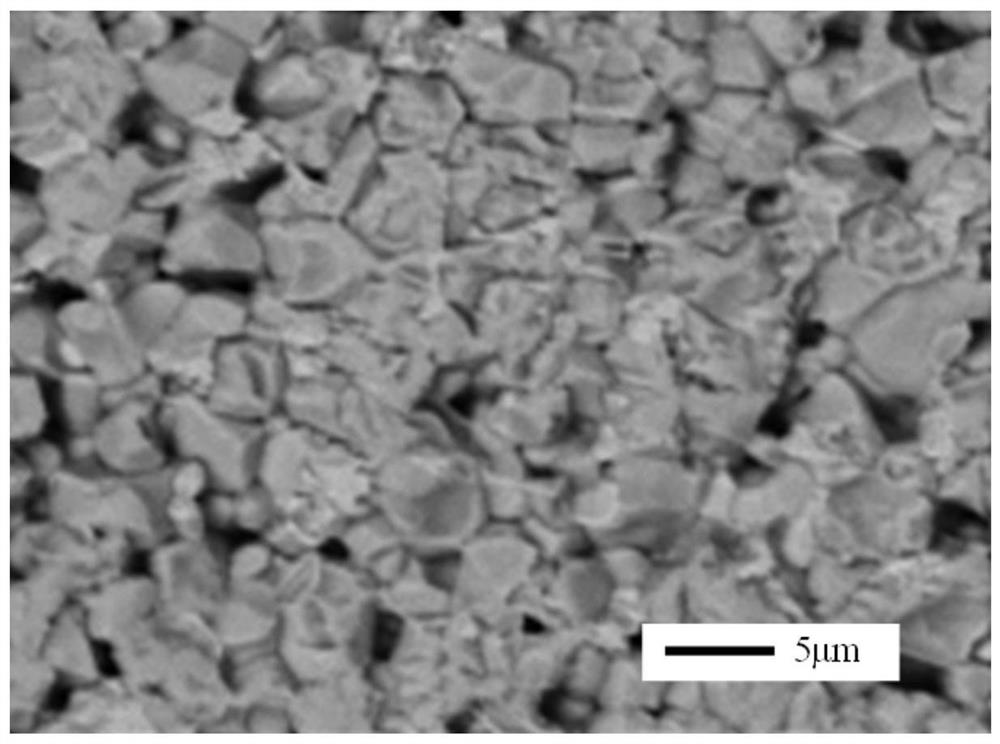

[0044] Step 2: Put Ti 33 mn 50 Cr 12 Fe 5 The alloy powder is pressed into shape, the pressing pressure is 150MPa, the holding time is 1min, and then sintered in the argon atmosphere, the temperature is 950°C, the time is 1h, and Ti 33 mn 50 Cr 12 Fe 5 porous alloy substrate.

[0045] Step 3: Take Ti 33 mn 50 Cr 12 Fe 5 The porous alloy substrate is used as the cathode, and the spectrally pure graphite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com