Conductive particles, method for producing same, and anisotropic conductive film

A technology of conductive particles and acid solution, which is applied in the field of conductive adhesives, can solve problems such as poor compatibility of organic matter, high material cost, and large filling amount, and achieve low cost, stable chemical properties, and good compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The present invention provides a method for preparing conductive particles. The method for preparing conductive particles includes the following steps:

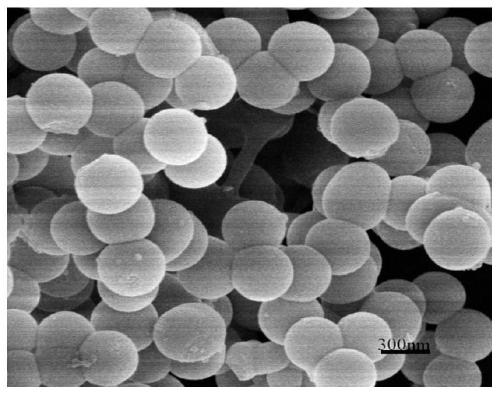

[0041] Using a silicon-containing precursor as a silicon source, water and alcohol as a mixed solvent, adding a surfactant, stirring, centrifuging and drying to obtain mesoporous silica balls;

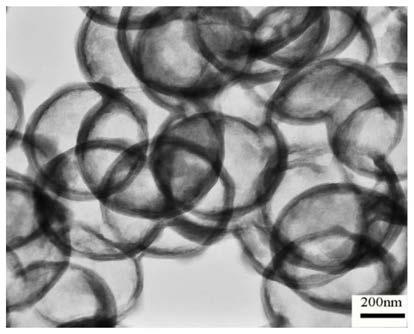

[0042] Using mesoporous silica spheres as a template, a resin solution as a carbon source, and water and alcohol as a mixed solvent, after stirring, curing and calcination, porous carbon spheres are obtained;

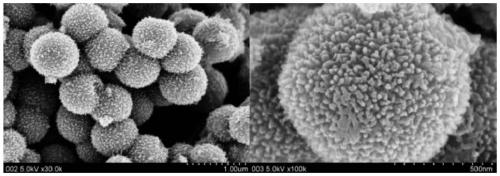

[0043] The aniline and the porous carbon ball are dissolved in an acidic solution, and an initiator is added. After washing and drying, a porous carbon ball polyaniline nanowire composite is obtained, and the porous carbon ball polyaniline nanowire composite is a conductive particle.

[0044] The present invention firstly adopts the sol-gel method to prepare mesoporous silica spheres. The silicon-containing precursor is used as t...

Embodiment 1

[0080] In this embodiment, the conductive particles are prepared by the following steps:

[0081] (1) Preparation of mesoporous silica spheres: mix 10 mL of absolute ethanol and 20 mL of deionized water to obtain a mixed solvent, and add 0.05 g of cetyltrimethylammonium bromide to the mixed solvent at 15°C , Stir uniformly at a speed of 100 rpm, then add 0.5 mL of ethyl orthosilicate and 0.2 mL of ammonia, continue to stir at a speed of 300 rpm for 3 hours, and centrifuge and dry to obtain hollow mesoporous silica balls.

[0082] (2) Preparation of porous carbon balls: Add 0.05g of mesoporous silica balls to 40mL of mixed solvent. The ratio of organic alcohol to water in the mixed solvent is 0.5:1. The organic alcohol is absolute ethanol, and then 0.2g is added. The phenolic resin solution with a mass concentration of 10% was stirred at 300 rpm for 5 hours, then poured into a petri dish, placed in an oven and cured at 80°C for 30 hours to obtain a yellow powder. Then the yellow pow...

Embodiment 2

[0085] In this embodiment, the conductive particles are prepared by the following steps:

[0086] (1) Preparation of mesoporous silica balls: Mix 30 mL of ethylene glycol and 30 mL of deionized water to obtain a mixed solvent, add 0.1 g of cetyltrimethylammonium bromide to the mixed solvent, and at a temperature of 25°C, Stir uniformly at a speed of 200 rpm, then add 1.5 mL of ethyl orthosilicate and 1.5 mL of ammonia water, continue to stir at a speed of 600 rpm for 10 hours, and centrifuge and dry to obtain hollow mesoporous silica balls.

[0087] (2) Preparation of porous carbon balls: Add 0.15g of mesoporous silica balls to 100mL of mixed solvent, where the ratio of organic alcohol to water in the mixed solvent is 1:1, organic alcohol is ethylene glycol, and then 1g mass is added The phenolic resin solution with a concentration of 30% was stirred at 500 rpm for 8 hours, then poured into a petri dish and placed in an oven at 100 ℃ for curing for 20 hours to obtain a yellow powde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com