Noble metal catalyst with activated carbon confinement and preparation method and application thereof

A precious metal catalyst, activated carbon technology, applied in nanotechnology for materials and surface science, electrical components, battery electrodes, etc., can solve the problems of catalyst agglomeration, deactivation, shedding, neglected correlation, etc., to achieve high local reaction concentration, quality The effect of activity enhancement and simple process route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The invention provides a preparation method of a noble metal catalyst confined by activated carbon, comprising the following steps:

[0047] A) disperse and mix noble metal salt, organic small molecule ligand, activated carbon black and organic solvent to obtain black colloid;

[0048] B) heating and drying the black colloids in sequence to obtain a precursor;

[0049] C) Calcining the precursor to obtain a noble metal catalyst.

[0050] In the present invention, firstly, noble metal salt, small organic molecule ligand, active carbon black and organic solvent are dispersed and mixed to obtain black colloid.

[0051] The present invention has no special restrictions on the dispersion method, and the dispersion method well known to those skilled in the art can be used. Those skilled in the art can select and adjust according to actual production conditions, raw material conditions and product requirements. The present invention is to ensure that activated carbon Suffici...

Embodiment 1

[0087] Weigh 7.5g of H 2 PtCl 6 ·6H 2 O, 3.35g of dicyandiamide, dispersed in 0.4L of ethanol, stirred at room temperature for 1h, then weighed 22g of KJ600, added the above dispersion solution, stirred at room temperature for 24h;

[0088] Stir the obtained product at 45°C and heat and evaporate for three days to allow the ethanol contained in the product to evaporate;

[0089] Collect the dry powder sample product, collect the dried sample into a ball mill jar and fully ball mill it into a powder, put it into a quartz porcelain boat, and calcinate it at 800°C for 2 hours in an argon atmosphere, and finally obtain a Pt-KJ noble metal catalyst.

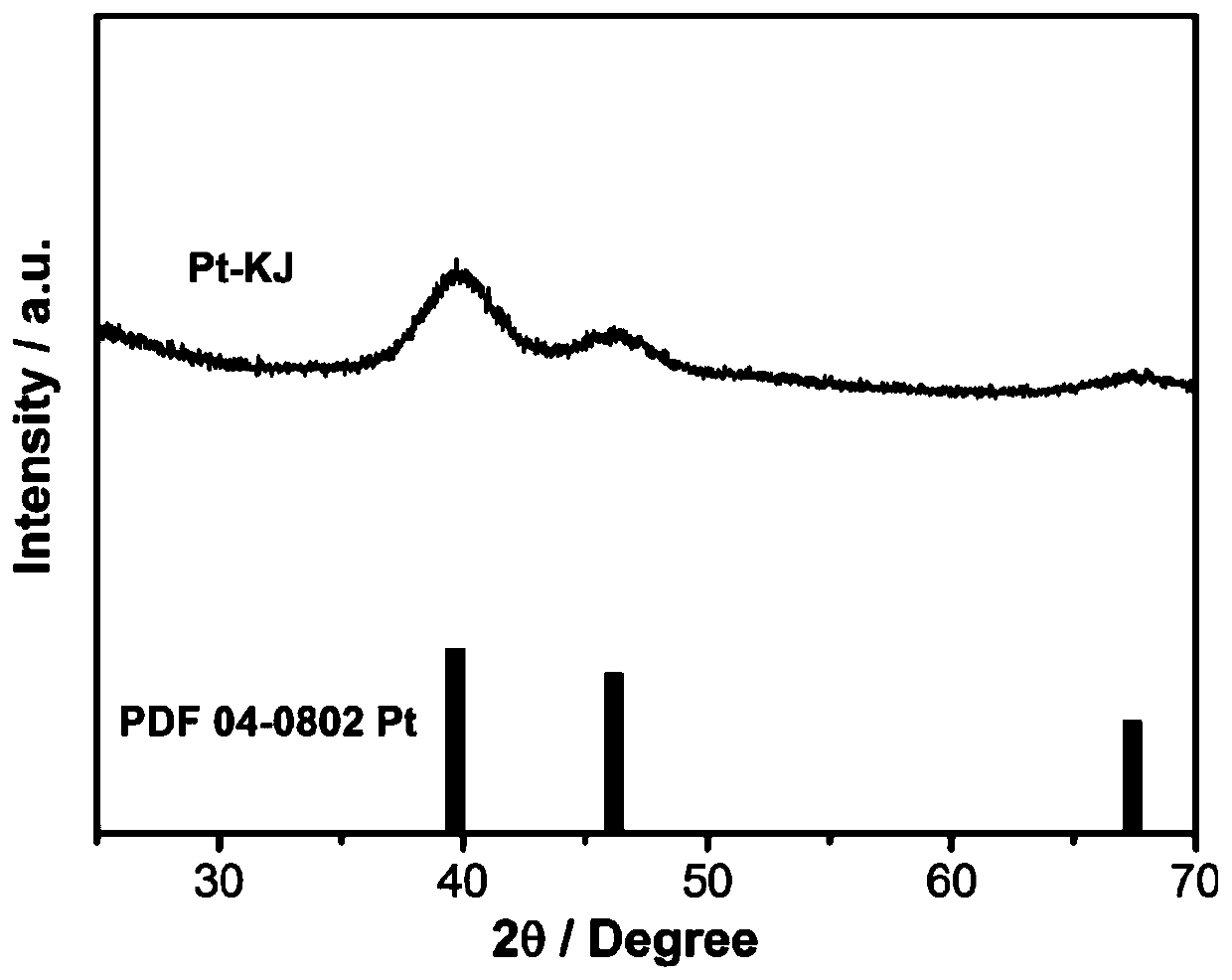

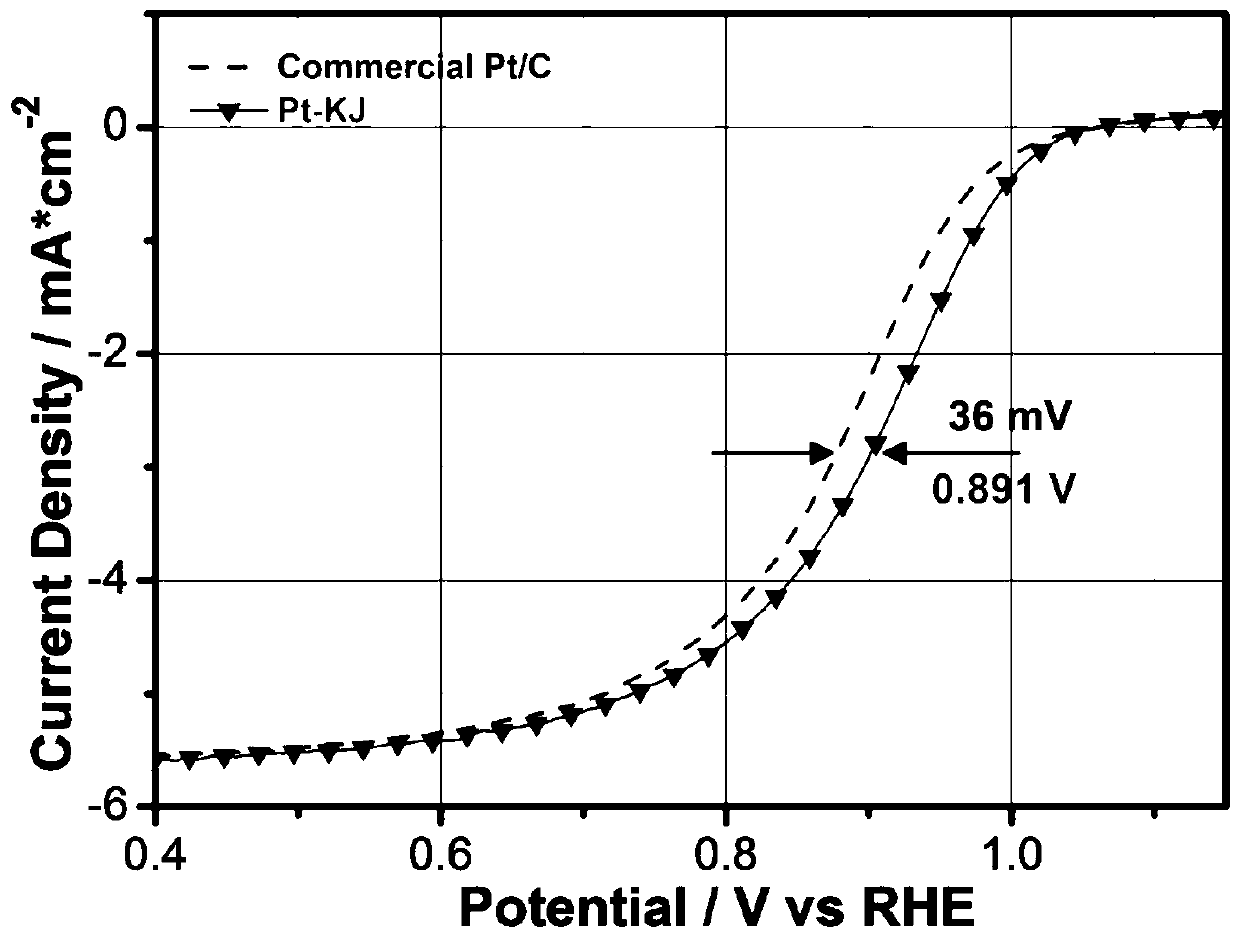

[0090] Using X-ray diffraction, transmission electron microscope, electrochemical test and other related characterizations, it is obtained as follows figure 1 , 2 , The results shown in 3. From figure 1 According to the X-ray diffraction pattern, the product can be obtained as small Pt single substance particles, and the grain s...

Embodiment 2

[0092] Weigh 15.5g of H 2 PtCl 6 ·6H 2 O, 2.3 g CoCl 2 ·6H 2 O, 29.5g of tetra-n-butylammonium iodide, dispersed in 0.4L of ethanol, stirred at room temperature for 1h, then weighed 44.5g of KJ600, added the above dispersion solution, stirred at room temperature for 24h;

[0093] The obtained product was placed in a heating stirrer at 45°C and heated and dried for three days to fully evaporate the ethanol solvent;

[0094] Collect the dry powder sample product, collect the evaporated sample into a ball mill jar and fully ball mill it into a powder, then put it into a quartz porcelain boat, and calcinate it at 800°C for 2 hours in an argon atmosphere, and finally get Pt 3 Co-KJ noble metal catalyst.

[0095] Utilize the same characterization as embodiment 1, obtain Figure 4 , 5 , 6 results. From Figure 4 We can see from the X-ray diffraction pattern of the synthesized Pt 3 Co nanoparticles, according to the Bragg equation fitting particle radius is about 2.4nm. pas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com