Method for preparing tissue engineering tendon materials by ultrasonic concussion technology

An ultrasonic vibration and tendon technology, applied in tissue regeneration, medical science, prosthesis, etc., can solve the problems of limiting the application of acellular tendons, unfavorable cell adhesion, migration and proliferation, etc., and achieves small damage, good biomechanical properties, low impact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1: Ultrasonic vibration technology is used in the preparation of bovine tendon acellular matrix:

[0034] 1) Take fresh bovine tendon / ligament, and remove the adventitia and synovial tissue on the surface of the tendon / ligament.

[0035] 2) Place the tendon / ligament in a vacuum freeze dryer at -56°C for 48 hours.

[0036] 3) The tendon / ligament structure is loosened by drying at low temperature through physical loosening methods such as extrusion, hammering, vacuum anti-explosion airflow impact and other methods.

[0037] 4) The loose tendon / ligament is further physically and mechanically combed to separate the tendon / ligament collagen fibers or collagen fiber bundles.

[0038] 5) Put the isolated collagen fibers or fiber bundles into 10mM hypotonic Tris solution, add 0.05% serine protease inhibitor (0.05% phenylmethylsulfonyl fluoride ethanol solvent, 35ml / L 50ml ethanol + 25mgPMSF), at room temperature The shaker was shaken for 12h. Pour off the solution, a...

Embodiment 2

[0041] Example 2: Histological examination

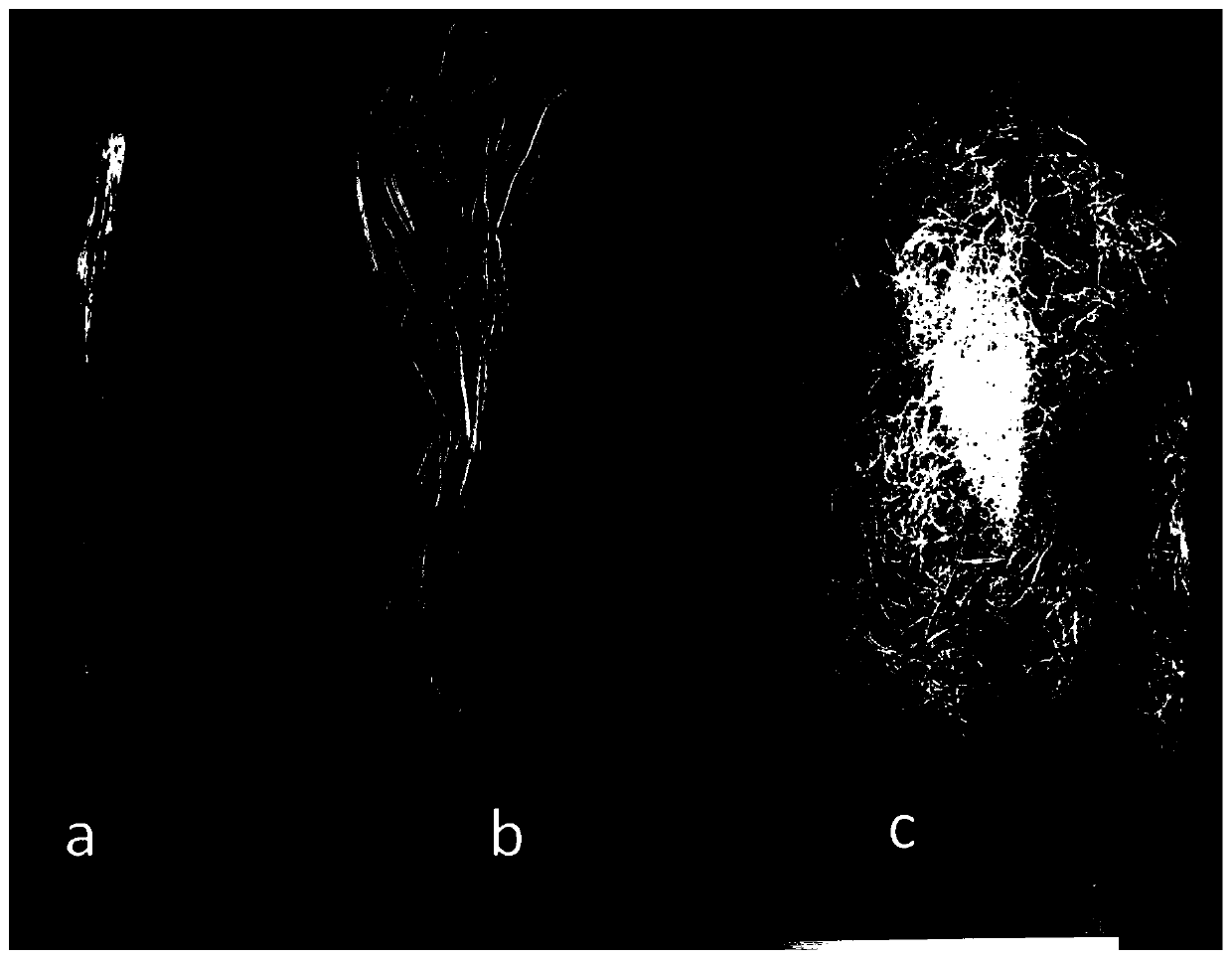

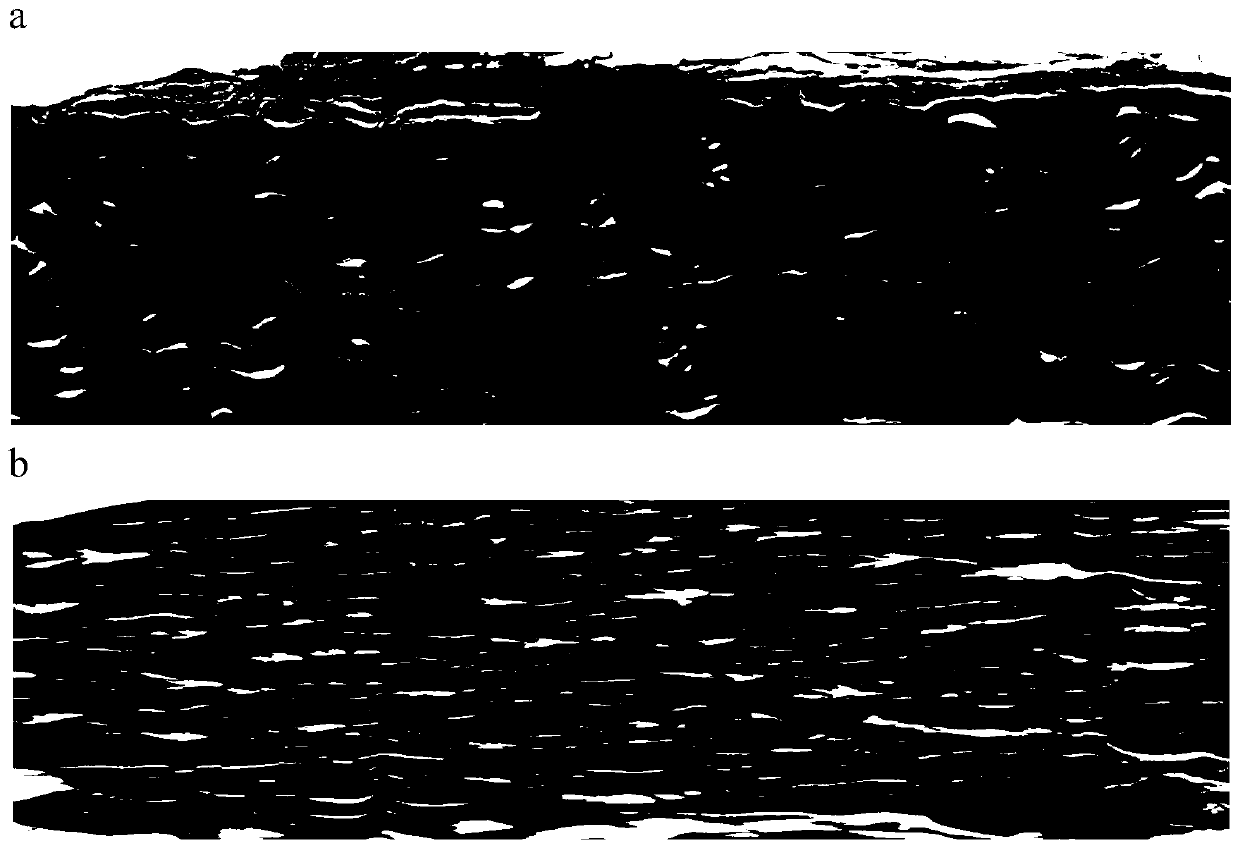

[0042] Collagen fibers or fiber bundles before and after decellularization were taken for paraffin embedding, sectioned (5 μm), and HE stained for observation. Observe the cell nucleus components (hematoxylin staining), collagen arrangement (eosin staining), and see that the cell components are completely removed ( figure 2 ).

Embodiment 3

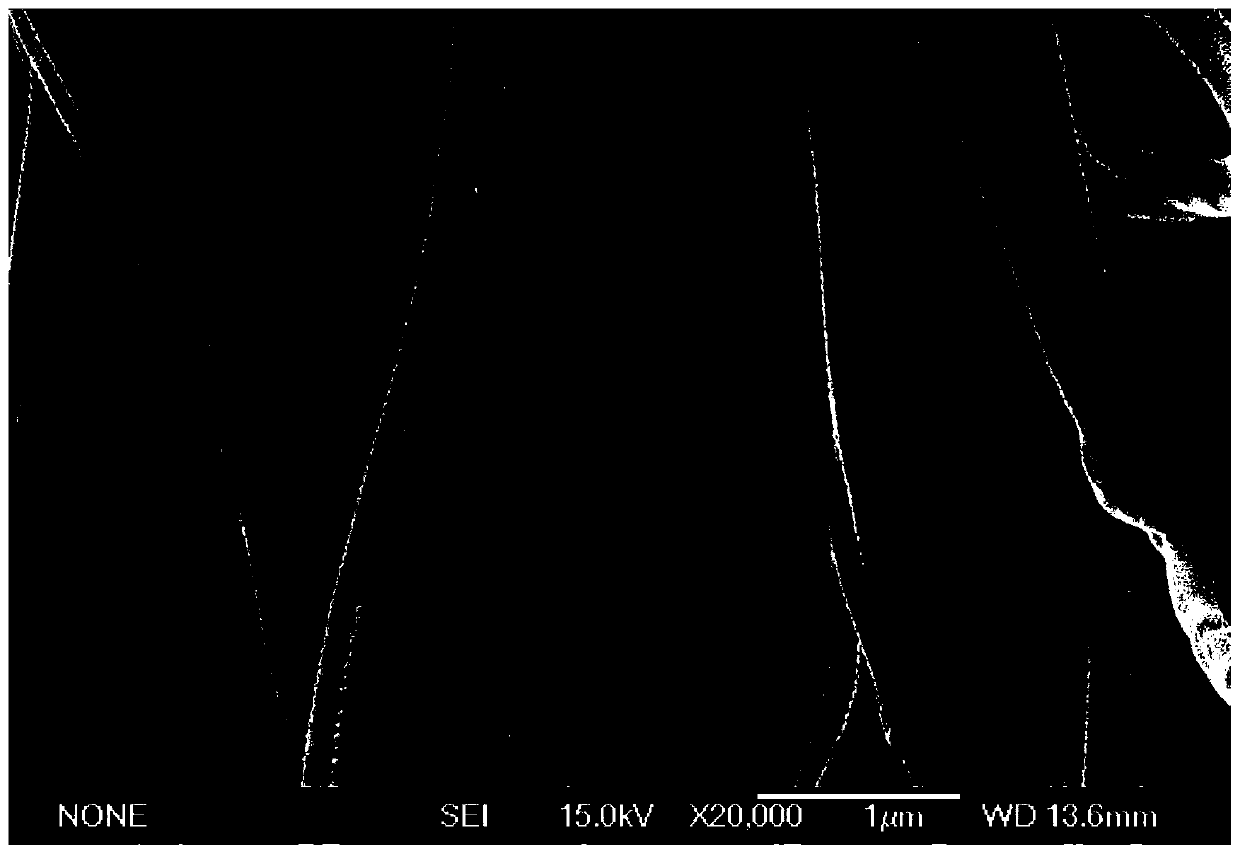

[0043] Embodiment 3: Electron microscope inspection

[0044] Cut the tendon acellular matrix into a length of about 5mm for later use, take the loading plate, fix the freeze-dried fresh tendon and freeze-dried tendon fiber bundle samples on the surface of the loading plate, spray gold powder, put it into the scanning electron microscope, and extract the internal air to be in a vacuum state , start detection. The results showed that the decellularization of tendon into three-dimensional helical structure did not change ( image 3 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com