Alcohol-based fuel stove

A technology of alcohol-based fuel and slurry, which is applied in the direction of heating fuel, liquid heating fuel, household stove/stove, etc., can solve the problems of closing down business, heavy losses, and the inability of alcohol-based fuel stoves to be used in household occasions, so as to reduce the waste Effects of carbon, stable combustion, and reduced warm-up time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

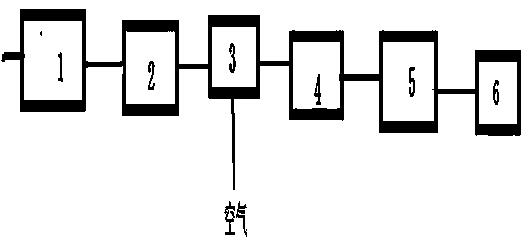

Method used

Image

Examples

Embodiment 1

[0041] The above-mentioned alcohol-based fuel stove, wherein the caliber of the safety valve is 20mm, the nominal diameter of the control valve is 20mm, the diameter of the gas hole on the fire distributor is 0.2mm, and the thickness of the aluminum-copper composite metal substrate is 1 mm, the thickness of the rare earth thick film dielectric layer is 60 microns, the rare earth thick film circuit includes 3 layers of rare earth thick film circuits, and the thickness of the single layer rare earth thick film circuit is 0.5-0.8 mm. The rare earth thick film dielectric layer is made by drying and sintering rare earth dielectric slurry, and the rare earth dielectric slurry includes; SiO 2 40 parts, TiO 2 20 parts, 5 parts of BaO, 20 parts of terpineol, 3 parts of ethyl cellulose, 2 parts of 1.4-butyrolactone, 6 parts of hydrogenated castor oil, 3 parts of lecithin; 2 parts of yttrium oxide. The viscosity of the slurry was 150 mPas.

[0042] The rare earth thick film circuit i...

Embodiment 2

[0045] Similar to Example 1, wherein the caliber of the safety valve is 50mm, the nominal diameter of the control valve is 40mm, the diameter of the gas hole on the fire distributor is 0.8mm, and the thickness of the aluminum-copper composite metal substrate is 2mm The rare earth thick film circuit includes 5 layers of superimposed rare earth thick film circuits, and the thickness of a single layer of rare earth thick film circuit is 0.1-0.3mm. 60 parts of SiO2 in the rare earth dielectric slurry, and 10 parts of tributyl citrate in the rare earth resistor slurry. In the preparation method of silicon carbide particles, the raw material ratio of the film layer is 60 parts of silicon carbide powder, 20 parts of polymer material, 12 parts of pore forming agent, 2 parts of curing agent, and organic solvent formaldehyde is used.

Embodiment 3

[0047] Similar to Example 1, wherein the caliber of the safety valve is 35mm, the nominal diameter of the control valve is 30mm, the diameter of the gas hole on the fire distributor is 0.5mm, and the thickness of the aluminum-copper composite metal substrate is 1.5 mm. mm, the thickness of the rare earth thick film dielectric layer is 80 microns. 5 parts of 1.4-butyrolactone in the rare earth medium slurry, and 4 parts of hydrogenated castor oil in the rare earth resistor slurry. In the preparation method of silicon carbide particles, the raw material ratio of the support body is 80 parts of silicon oxide powder, 12 parts of polymer material, 2 parts of curing agent, organic solvent formaldehyde is used, and the thickness of the film layer is 500 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com