Preparation method and application of a nickel cobalt oxide porous material

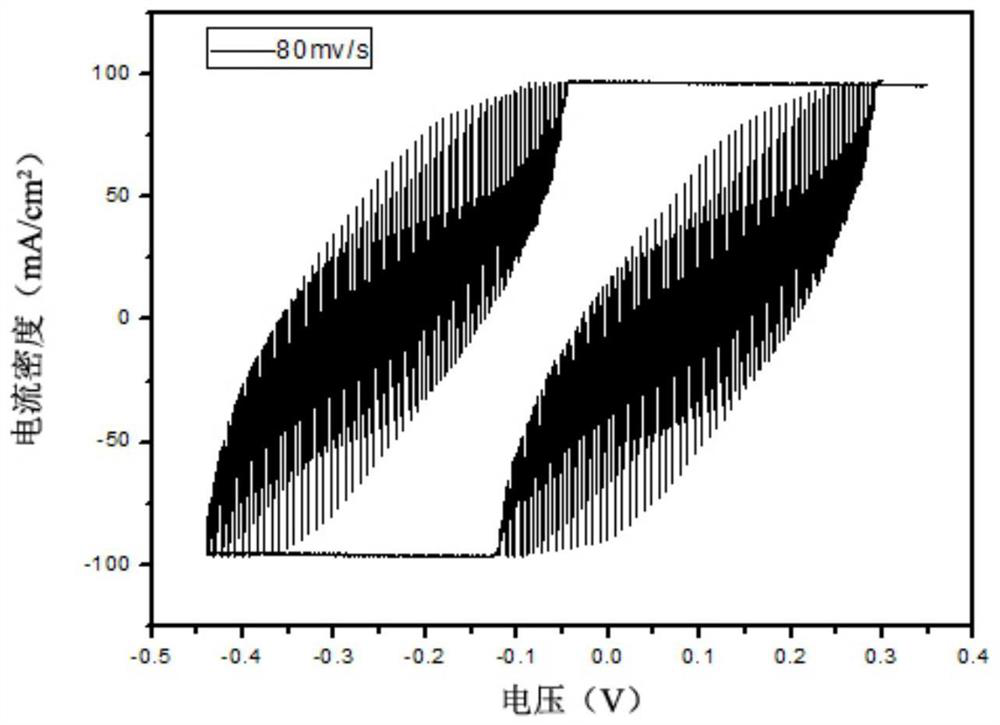

A porous material, nickel cobalt oxide technology, applied in nanotechnology for materials and surface science, chemical instruments and methods, nickel compounds, etc. The effect of large surface area and high energy storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

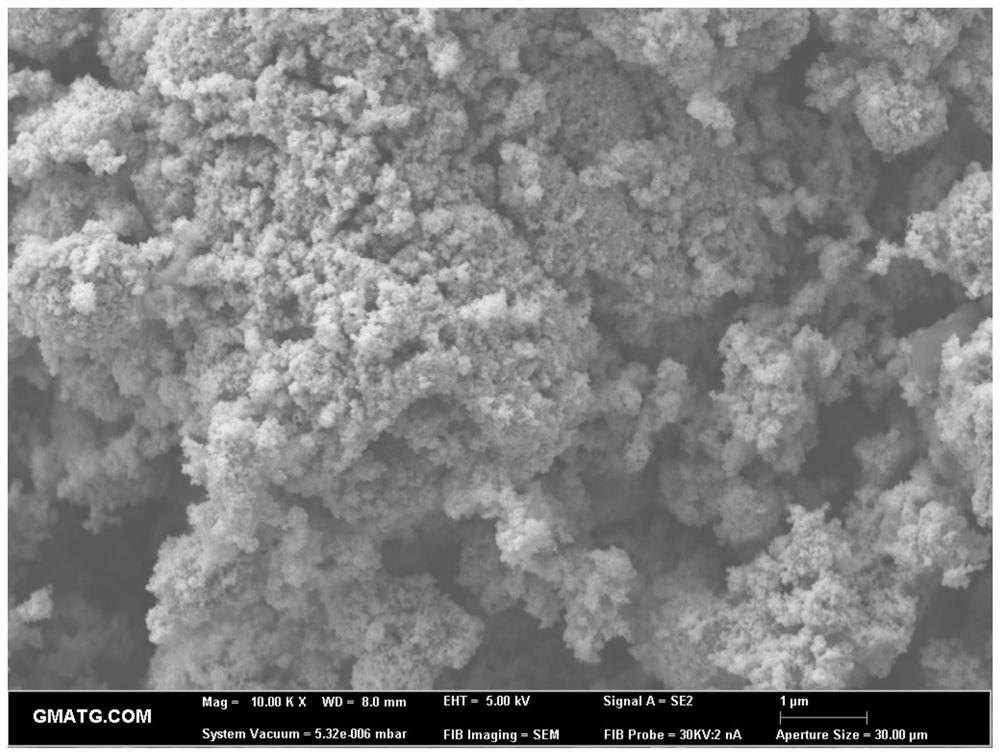

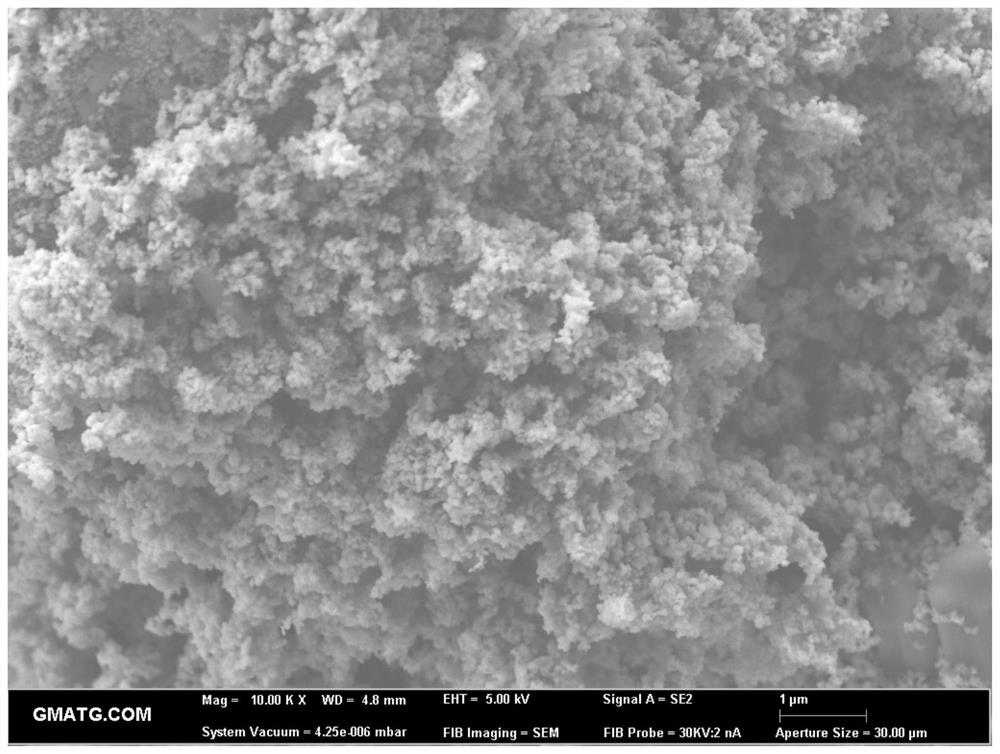

[0037] A preparation method of nickel cobaltate porous material, measure 50mL polyethylene glycol 400 in a beaker, weigh 5.8g of cobalt nitrate hexahydrate, 2.9g of nickel nitrate hexahydrate, 0.09g of sodium nitrate and add to the beaker, slowly stir to make it Disperse in polyethylene glycol 400, then weigh 10g of urea and add it to a beaker, use an ultrasonic cleaner to perform ultrasonication for 1 hour, then put the resulting solution in an oil bath, heat to 100°C, and stir at a constant temperature for 2 hours. The stirring speed is 300r / min; after the reaction, take the solution out and cool it to room temperature, transfer it to a square crucible, place it in a muffle furnace, and heat it to 300°C for 2 hours at a constant temperature under the condition of being in contact with air, then heat it to 400°C ℃ constant temperature treatment for 6 hours, the heating rate is 2-3 ℃ per minute, after it is cooled to obtain a black solid, which is ground with a grinding bowl to...

Embodiment 2

[0039] A preparation method of nickel cobaltate porous material, measure 45mL polyethylene glycol 400 in a beaker, weigh 5.8g of cobalt nitrate hexahydrate, 2.9g of nickel nitrate hexahydrate, 0.1g of sodium nitrate and add to the beaker, slowly stir to make it Disperse in polyethylene glycol 400, then weigh 15g of urea and add it to a beaker, use an ultrasonic cleaner to perform ultrasonication for 1 hour, then put the resulting solution in an oil bath and heat it to 100°C, and react with magnetic stirring for 2 hours at a stirring speed of 300r / min: After the reaction is over, take the solution out and cool it to room temperature, transfer it to a square crucible, place it in a muffle furnace, and heat it to 300°C for 2 hours at a constant temperature under the condition of being in contact with air, then heat it to 400°C Constant temperature treatment was carried out for 6 hours, the heating rate was 2-3°C per minute, and a black solid was obtained after cooling, which was ...

Embodiment 3

[0041] A preparation method of nickel cobaltate porous material, measure 40mL polyethylene glycol 400 in a beaker, weigh 5.8g of cobalt nitrate hexahydrate, 2.9g of nickel nitrate hexahydrate, 0.1g of sodium nitrate and add to the beaker, slowly stir to make it Disperse in polyethylene glycol 400, then weigh 15g of urea and add it to a beaker, use an ultrasonic cleaner to perform ultrasonication for 1 hour, then put the resulting solution in an oil bath and heat it to 100°C, and react with magnetic stirring for 2 hours at a stirring speed of 330r / min: After the reaction is over, take the solution out and cool it to room temperature, transfer it to a square crucible, place it in a muffle furnace, and heat it to 400°C for 6 hours at a constant temperature under the condition of being in contact with air, with a heating rate of 2-3 °C per minute, wait for it to cool down to obtain a black solid, and grind it with a grinding bowl to finally obtain a nickel cobalt oxide porous mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com