Method for converting black oil shale semi-coke into white product

A semi-coke and black technology of oil shale, which is applied in the field of comprehensive utilization of solid waste resources and high-value utilization of deep processing, can solve problems such as environmental pollution and waste of resources, and achieve good product dispersion, simple process, and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Weigh 6 kg of oil shale semi-coke powder, spray 0.6 kg of water into it evenly, mix well, press it into a thin slice with a thickness of 1 mm with a pair of rollers, and then calcinate at 300°C for 4 hours in an air atmosphere to obtain a solid Product A;

[0020] Weigh 5 kg of solid product A and evenly disperse it into 50 kg of hydrogen peroxide solution with a mass concentration of 30%, adjust the pH value of the solution to 6 with sulfuric acid, and then react for 2 hours under stirring at 50°C; centrifuge the reacted suspension to obtain a solid product B;

[0021] Disperse the solid product B into 50 kg of 1mol / L oxalic acid solution, and react for 2 hours under stirring at 80°C to obtain the acid-washed solid product C;

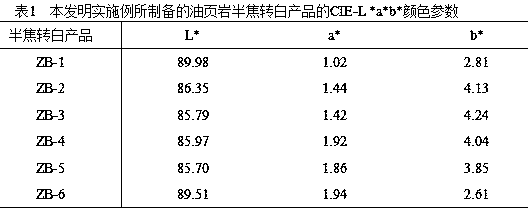

[0022] The acid-washed solid product C was calcined at 500°C for 2 hours to obtain a semi-coke-turned-white product, marked as BJZB-1, and its L*, a*, b* color parameters are shown in Table 1.

Embodiment 2

[0024] Weigh 6 kg of oil shale semi-coke powder, spray 1.2 kg of water evenly into it, mix well, press it into a thin slice with a thickness of 2 mm with a pair of rollers, and then calcinate at 600°C in air for 2 hours to obtain Solid product A;

[0025] Weigh 5 kg of solid product A and evenly disperse it into 100 kg of hydrogen peroxide solution with a mass concentration of 5%, adjust the pH value of the solution to 3 with sulfuric acid, and then react at 90°C for 1 h; centrifuge the reacted suspension to obtain a solid Product B; redisperse the solid product B into 50 kg of 4 mol / L sulfuric acid solution, and react for 1 hour under stirring at 70°C to obtain the acid-washed solid product C;

[0026] Finally, the acid-washed solid product C was calcined at 900°C for 2 hours to obtain a semi-coke-turned-white product, marked as BJZB-2, and its L*, a*, b* color parameters are shown in Table 1.

Embodiment 3

[0028] Weigh 6 kg of oil shale semi-coke powder, spray 1 kg of water evenly into it, mix thoroughly, press it into thin slices with a thickness of 1.5 mm with a pair of rollers, and then calcinate at 400 °C for 2 hours in air atmosphere to obtain Solid product A;

[0029] Weigh 5 kg of solid product A and evenly disperse it into 60 kg of hydrogen peroxide solution with a mass concentration of 10%, adjust the pH value of the solution to 4 with sulfuric acid, and then react at 70°C for 2 h with stirring; centrifuge the reacted suspension to obtain solid product B;

[0030] The solid product B was redispersed into 100 kg of 2mol / L nitric acid solution, and reacted under stirring at 80°C for 1.5 h to obtain the acid-washed solid product C;

[0031] Finally, the acid-washed solid product C was calcined at 600°C for 2 hours to obtain a semi-coke-turned-white product, marked as BJZB-3, and its L*, a*, b* color parameters are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com