Porous carbon mixed carbon black roll electrode material and preparation method and application thereof

A technology of electrode material and porous carbon, which is applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., to achieve the effects of improving stability, increasing production, and increasing the degradation effect of organic matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

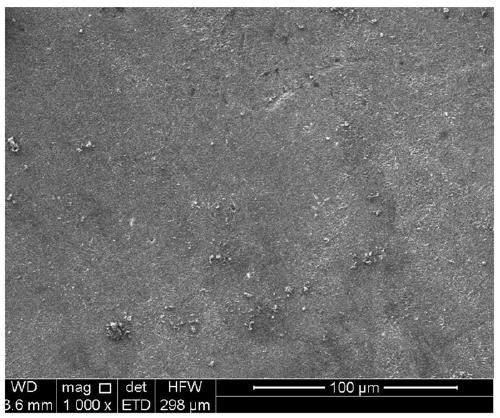

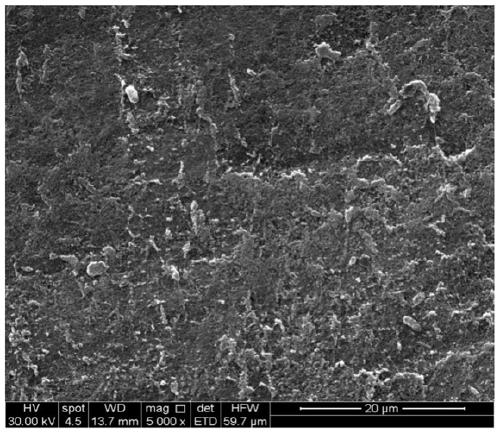

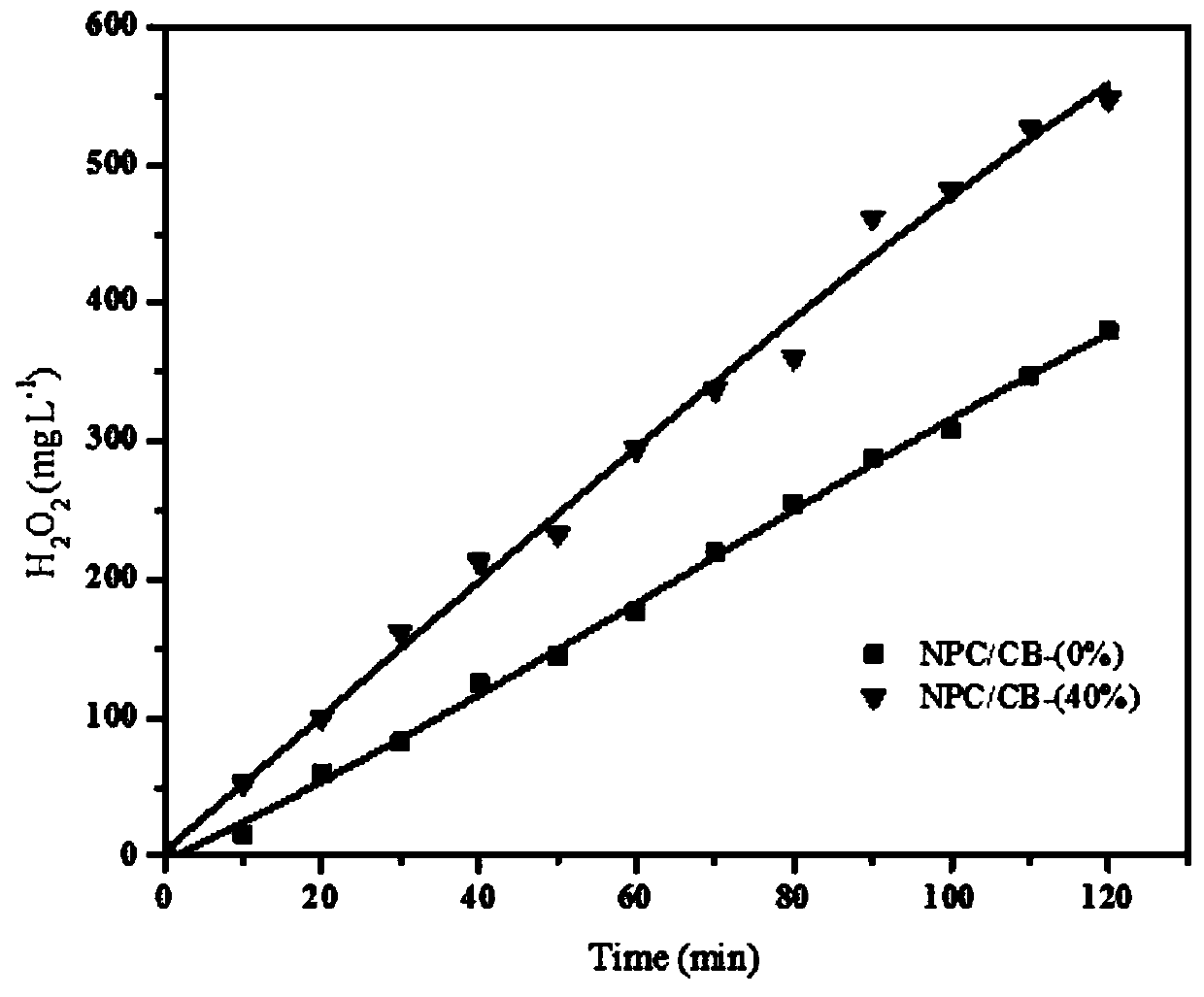

Image

Examples

preparation example Construction

[0034] A kind of preparation method of the porous carbon mixed carbon black rolling electrode material effectively applied in the electric Fenton technology system of the present invention comprises the following steps,

[0035] Step 1, with 100~150ml ultrapure water or deionized water as solvent, Zn(NO 3 ) 2 ·6H 2 O and 2-methylimidazole are added, at this time Zn(NO 3 ) 2 ·6H 2 The concentration ratio of O and 2-methylimidazole is 74.4g / L:(114.03~159.64)g / L. After the compound reaction is complete through 200~500rpm magnetic stirring for 12~24h, use a high-speed centrifuge at 8000~10000rpm. Methanol was used as a cleaning agent to completely remove the residue of 2-methylimidazole, and centrifuged for 8-20 minutes to obtain the precursor of porous carbon;

[0036] Step 2, dry the precursor of porous carbon in a vacuum drying oven at 45-65 °C for 5-12 hours; put the dried precursor into a quartz boat, and pass an inert gas into a high-temperature tube furnace, such as N ...

Embodiment 1

[0043] A kind of preparation method of the porous carbon mixed carbon black rolling electrode material that the present invention is applied in the electric Fenton technology system comprises the following steps,

[0044] Step 1, with 100ml ultrapure water as solvent, Zn(NO 3 ) 2 ·6H 2 O and 2-methylimidazole are added, at this time Zn(NO 3 ) 2 ·6H 2 The concentration ratio of O and 2-methylimidazole is 74.4g / L:114.03g / L. After the compound reaction is complete by 200rpm magnetic stirring for 12h, use methanol as a cleaning agent at 8000rpm in a high-speed centrifuge to remove 2-methylimidazole The imidazole residues were completely removed, and centrifuged for 8 minutes to obtain the precursor of porous carbon;

[0045] Step 2, dry the precursor of porous carbon in a vacuum oven at 45 ° C for 5 h; put the dried precursor into a quartz boat, and pass an inert gas into a high-temperature tube furnace, such as N 2 After calcination and carbonization at 908°C for 5 hours, b...

Embodiment 2

[0055] A kind of preparation method of the porous carbon mixed carbon black rolling electrode material that the present invention is applied in the electric Fenton technology system comprises the following steps,

[0056] Step 1, with 125ml deionized water as solvent, Zn(NO 3 ) 2 ·6H 2 O and 2-methylimidazole are added, at this time Zn(NO 3 ) 2 ·6H 2 The concentration ratio of O and 2-methylimidazole is 74.4g / L:136.62g / L. After the compound reaction is complete by 300rpm magnetic stirring for 24h, use methanol as a cleaning agent at 9000rpm in a high-speed centrifuge to remove 2-methylimidazole The imidazole residues were completely removed, and centrifuged for 20 minutes to obtain the precursor of porous carbon;

[0057] Step 2, dry the porous carbon precursor at 50°C for 12 hours in a vacuum drying oven; put the dried precursor into a quartz boat, and pass an inert gas, such as N 2 After calcination and carbonization at 1100°C for 6 hours, black powder porous carbon wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com