Method for preparing manganese sulfate solution through manganese oxidized ore thermal-storage reducing roasting

A manganese sulfate solution and manganese oxide ore technology, applied in manganese sulfate and other directions, can solve the problems of high iron content in leaching liquid, long reaction time, fast reaction speed, etc., and achieve simple flue gas treatment, short leaching time, and short roasting time. Effect

Pending Publication Date: 2019-11-05

GUIZHOU UNIV

View PDF5 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The one-step method of the two mines takes a long time to react, the reaction system needs to be heated, the consumption of the reducing agent pyrite is large, the iron content of the leaching solution is high, the iron removal is difficult and the amount of slag is large, so far only a few enterprises use it

[0013] During the reaction process of sulfur dioxide and sulfite leaching, the pH value regulation is highly required. When the pH value is too low, the utilization rate of the reducing agent is low, and the by-product of manganese dithionate will inevitably be produced during the reaction process, which is harmful to the manganese sulfate solution. There is a certain impact on quality

Ferrous sulfate leaching method and iron filings leaching method have fast reaction speed and low requirements on the temperature of the reaction system. The leaching effect of manganese in ore is ideal, but the amount of slag is large, the cost is high, and the secondary utilization of waste slag is difficult.

[0014] Biomass leaching method, glucose leaching method, waste molasses leaching method and other organic reducing agent direct reduction leaching methods all have the disadvantages of long reaction time, high acid consumption and high residual organic matter in manganese sulfate solution

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

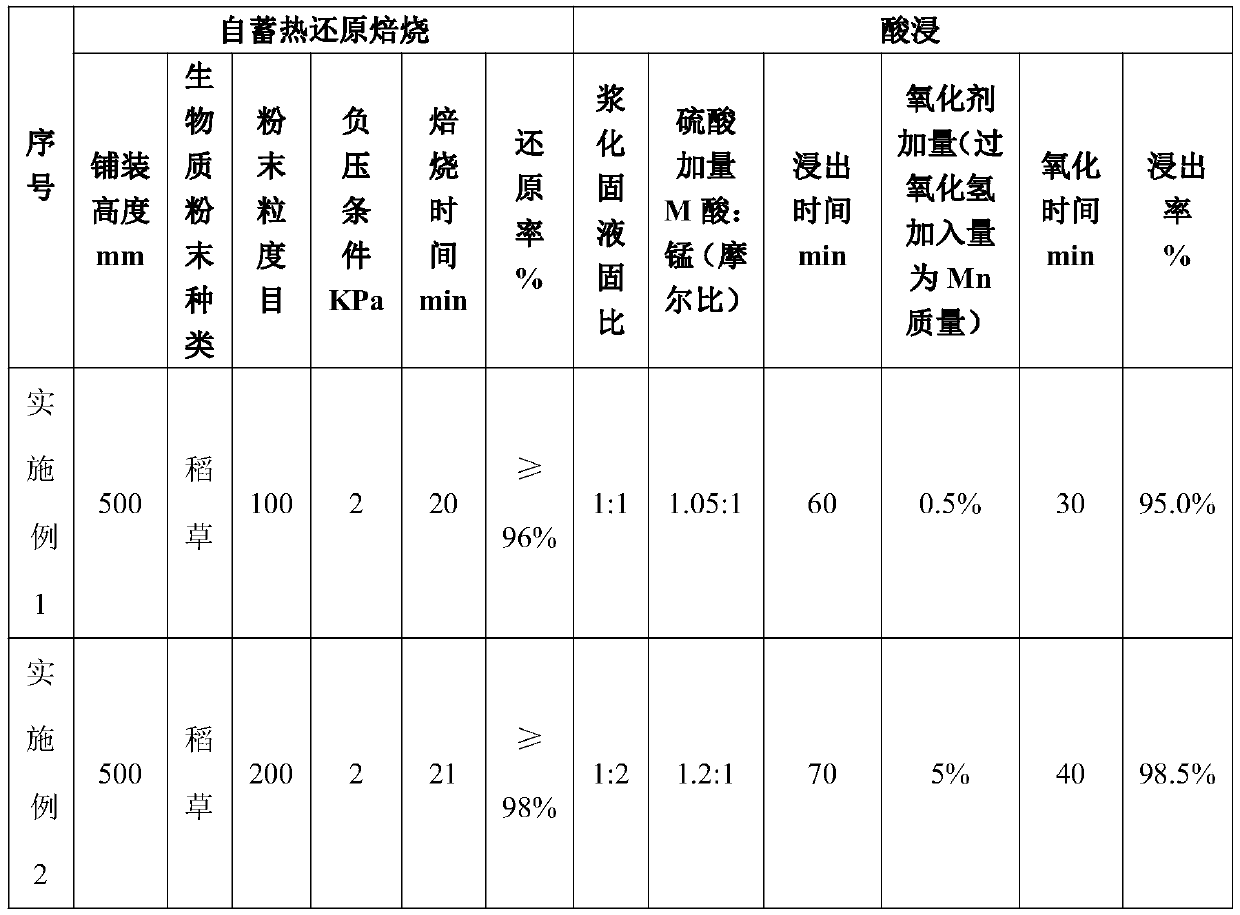

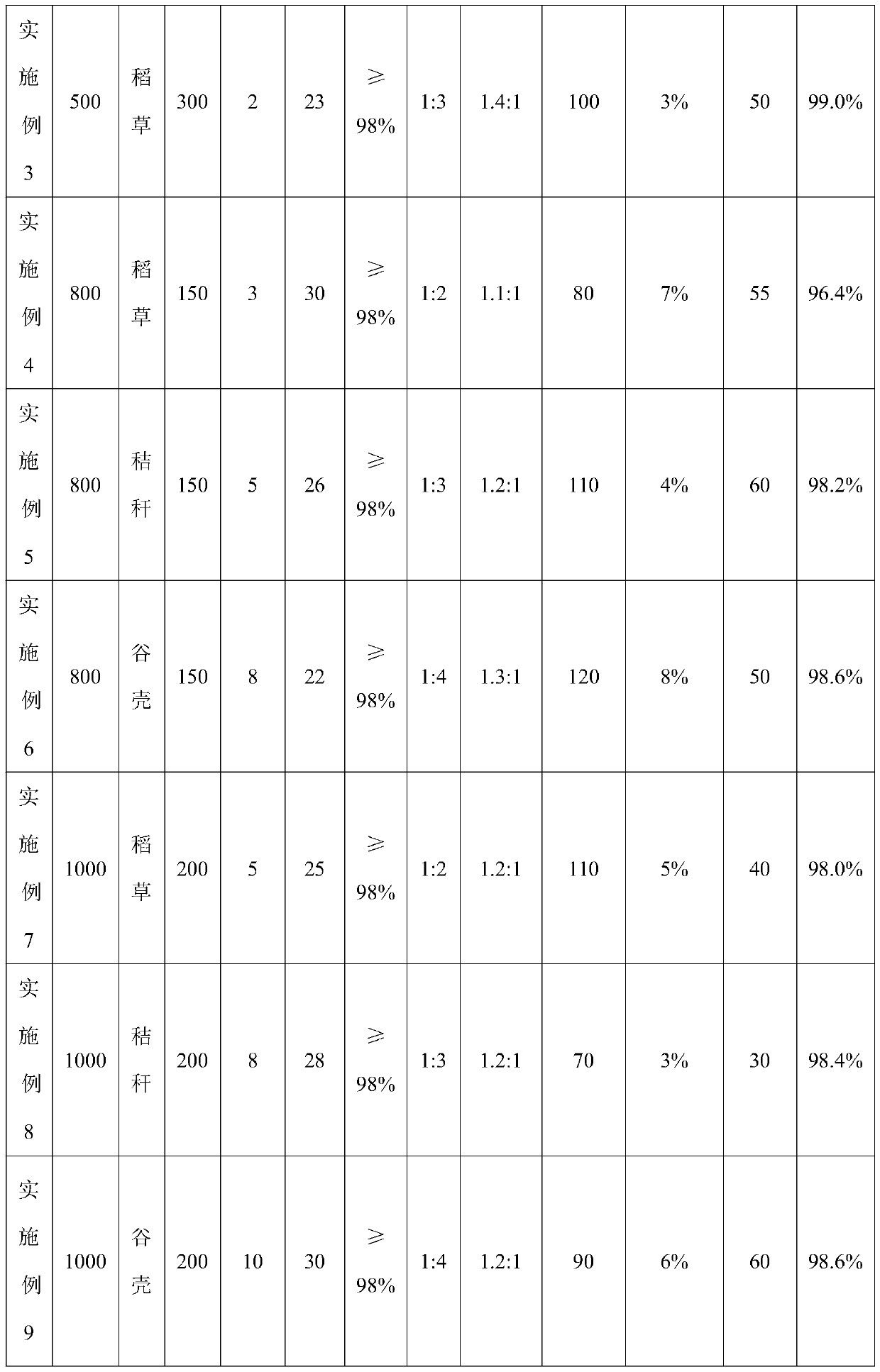

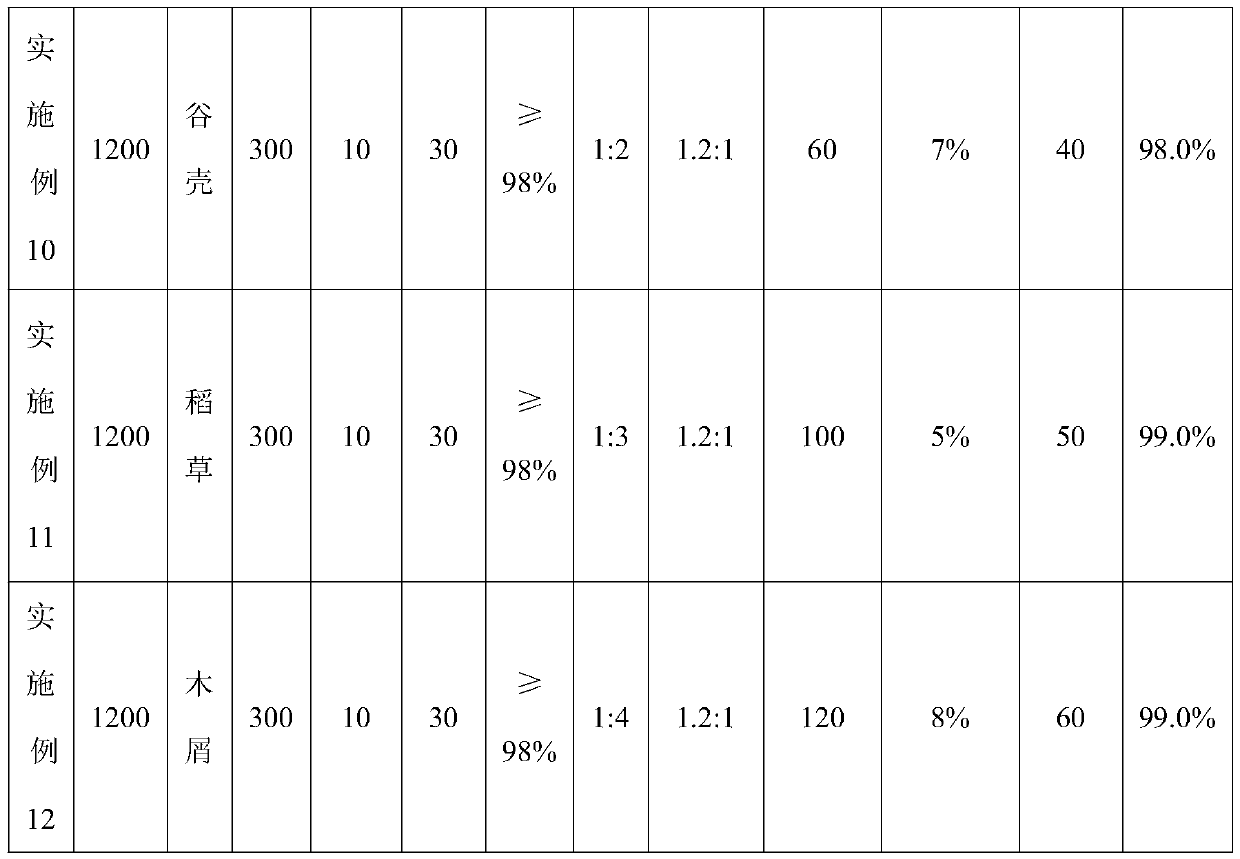

[0044] The present invention will be further described below in conjunction with the examples, but not as a basis for limiting the present invention.

[0045]

[0046]

[0047]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a method for preparing a manganese sulfate solution through manganese oxidized ore thermal-storage reducing roasting. Preparation is performed according to the following stepsthat (1) manganese oxidized ore is crushed, biomass powder is added, mixing and uniform stirring are performed, then a mixture is spread into a roasting box with ventilation holes in the bottom, the material layer is combusted from the surface layer to the bottom layer under the negative micro-pressure air draft, the combustion layer moves to the bottom of the material layer, and then the roastingprocess is finished, so that thermal reducing-roasted ore is obtained; and (2) water, dilute sulphuric acid or electrolytic manganese anolyte are added into a leaching barrel, the thermal reducing-roasted ore is added into the barrel, stirring is performed so that pulp liquid is prepared, then sulfuric acid is added into the pulp liquid, stirring and reaction are performed, then hydrogen peroxideis added, stirring and reaction continue, then a manganese sulfate acid leaching solution is obtained, the acid leaching solution is subjected to neutralization, iron removal and purification, and then the manganese sulfate solution is obtained. The method has the characteristics that the source of reducing agents is wide, the price of the reducing agents is low, the reducing speed is high, the equipment investment is low, energy consumption is low, the manganese reducing leaching rate is high, and the scale is flexible, and the defects in the prior art can be overcome.

Description

technical field [0001] The invention relates to a method for preparing manganese sulfate solution by thermal storage and reduction roasting of manganese oxide ore, which belongs to the field of hydrometallurgy and chemical solution preparation. Background technique [0002] Manganese sulfate is a basic manganese salt, which is widely used in metallurgy, chemical industry, battery, feed and other industries. It is the basis for the preparation of high-purity manganese sulfate, nickel-cobalt-manganese ternary materials such as electrolytic metal manganese, electrolytic manganese dioxide, and trimanganese tetraoxide. raw materials. [0003] Manganese sulfate is generally prepared by leaching rhodochrosite with sulfuric acid and removing impurities, but with the large-scale development of rhodochrosite resources, the grade is gradually depleted, and the impurity content after leaching rhodochrosite is high, the impurity removal procedure is complicated, the cost of impurity remo...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22B3/08C22B1/02C22B47/00C01G45/10

CPCC01G45/10C22B1/02C22B3/08C22B47/00

Inventor 王海峰王家伟

Owner GUIZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com