Use of an amide compound as a sulfide mineral inhibitor

An amide compound and inhibitor technology, applied in solid separation, flotation and other directions, to achieve high-efficiency flotation separation, strong selectivity, and low dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

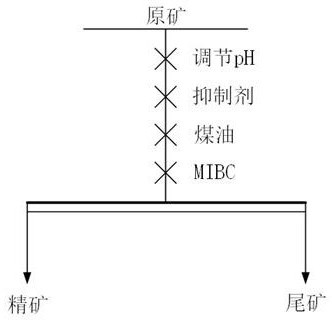

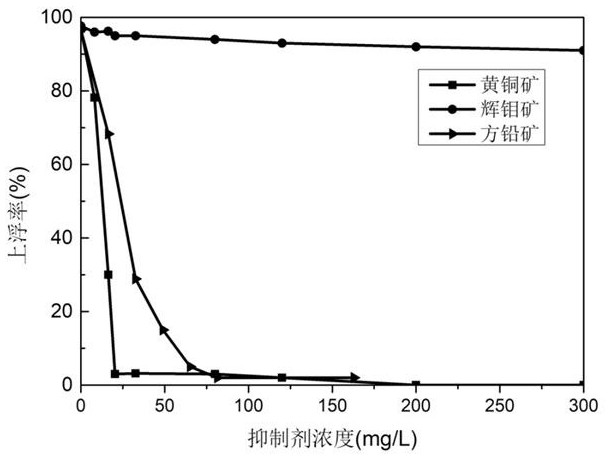

[0037] Take 2g of molybdenite, chalcopyrite, and galena single minerals with a particle size of +38-74μm for flotation respectively, take 50mL of distilled water and add it to a 70mL hanging tank flotation machine, and stir at a speed of 1300r / min to adjust the slurry , so that the slurry is fully dispersed.

[0038] Adjust the pH of the pulp to 10, according to figure 1 Described medicament system adds medicament, after adding medicament, stirs successively 5min, 2min, 1min, inhibitor is N-(3-mercapto-2-methylpropanoyl) glycine, collector is kerosene, methyl isobutyl Methanol (MIBC) was the foaming agent. Inhibitor concentrations are 0, 8.2, 16.3, 20.4, 32.6, 80, 120, 200, 300mg / L; collector and MIBC concentrations are 20mg / L; after stirring, air flotation to obtain foam products and tailings .

[0039] Filter, dry and weigh the foam product and tailings respectively, and calculate the floating rate. The results are as follows: figure 2 shown.

[0040] It can be seen fr...

Embodiment 2

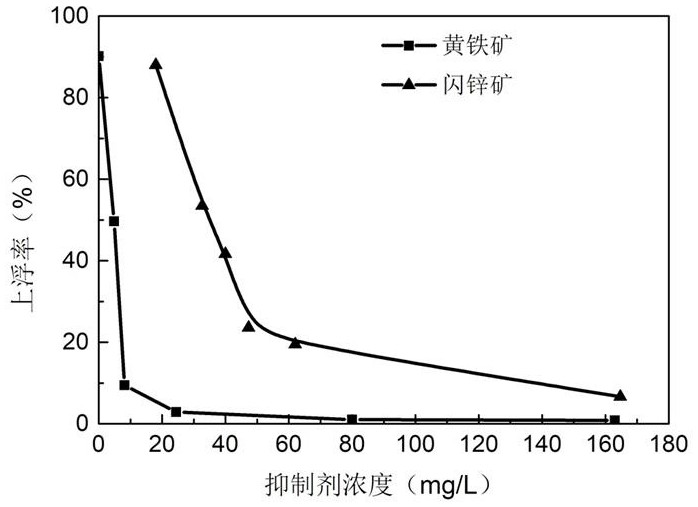

[0042] Take 2g of sphalerite, pyrite and other single minerals with a particle size of +38-74μm for flotation respectively, take 50mL of distilled water and add it to a 70mL hanging tank flotation machine, stir and adjust the slurry at a speed of 1300r / min to make the slurry fully dispersion.

[0043] To adjust the pH of the pulp, add N-(3-mercapto-2-methylpropanoyl)glycine, butyl xanthate (20mg / L), MIBC (20mg / L) in sequence, and the inhibitor concentrations are 0, 8.2, 16.3, 20.4, 32.6, 80, 120, 200, 300mg / L, after adding the medicine, stir for 5min, 3min, 1min in turn. After the stirring is completed, air flotation is carried out to obtain foam products and tailings.

[0044] Filter, dry and weigh the foam product and tailings respectively, and calculate the floating rate. The results are as follows: image 3 shown.

[0045]As can be seen from the examples, N-(3-mercapto-2-methylpropanoyl) glycine has a strong inhibitory ability to pyrite and sphalerite, and when the inhi...

Embodiment 3

[0047] Take 2g of molybdenite, chalcopyrite, and galena single minerals with a particle size of +38-74μm for flotation respectively, take 50mL of distilled water and add it to a 70mL hanging tank flotation machine, and stir at a speed of 1300r / min. pulp to fully disperse the pulp.

[0048] The order of adding the medicaments is as follows: figure 1 As shown, the concentrations of N-(3-mercapto-2-methylpropanoyl)glycine added to molybdenite, chalcopyrite, and galena were 24.45, 24.45, and 48.9 mg / L, respectively, and were collected by kerosene The agent is methyl isobutyl carbinol (MIBC) as foaming agent. The concentration of collector and MIBC is 20mg / L, and the pH of the pulp is adjusted to 4, 5, 6, 8, 10, 12 before adding the agent. After the stirring is completed, air flotation, the obtained foam product and tailings, the results are as follows Figure 4 shown.

[0049] As can be seen from the examples, N-(3-mercapto-2-methylpropanoyl) glycine has almost no inhibitory e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com