Tile antiskid agent and preparation method thereof

An anti-slip agent and ceramic tile technology, applied in the field of ceramic tile surface treatment, can solve the problems of dry slip without anti-slip effect, pedestrians slipping accidentally, accidents, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A tile anti-slip agent, comprising the following raw materials in parts by weight:

[0036]

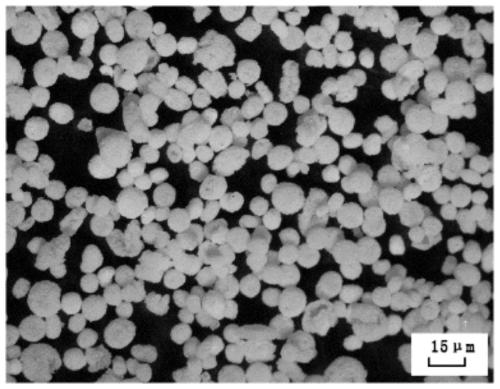

[0037] Wherein, the particle size of the polymer foam material is 13 μm.

[0038] The polymer foaming material is a foaming resin doped with inorganic oxides.

[0039] The weight ratio of the foamed resin to the inorganic oxide is 20:1.5.

[0040] The inorganic oxide is titanium dioxide modified by silane coupling agent A172 and maleic anhydride grafted polypropylene; the foaming resin is phenolic resin.

[0041] The fluoride salt is made by mixing ammonium fluoride and ammonium bifluoride in a weight ratio of 3.5:1; the penetrating agent is made by mixing fatty alcohol polyoxyethylene ether and alkylphenol polyoxyethylene ether in a weight ratio of 1:3 .

[0042] The brightener is formed by mixing a nonionic surfactant and an anionic surfactant in a weight ratio of 1.5:7; the anionic surfactant is sodium dodecylbenzenesulfonate, sodium lauryl sulfate It is mixed with so...

Embodiment 2

[0050] A tile anti-slip agent, comprising the following raw materials in parts by weight:

[0051]

[0052]

[0053] Wherein, the particle diameter of the polymer foaming material is 5 μm.

[0054] The polymer foaming material is a foaming resin doped with inorganic oxides.

[0055] The weight ratio of the foamed resin to the inorganic oxide is 20:1.

[0056] The inorganic oxide is titanium dioxide modified by silane coupling agent KH550 and maleic anhydride grafted polypropylene; the foaming resin is polyurethane resin.

[0057] The fluoride salt is made by mixing ammonium fluoride and ammonium bifluoride in a weight ratio of 3:1; the penetrating agent is made by mixing fatty alcohol polyoxyethylene ether and alkylphenol polyoxyethylene ether in a weight ratio of 1:1 .

[0058] The brightener is formed by mixing a nonionic surfactant and an anionic surfactant at a weight ratio of 1:5; the anionic surfactant is sodium dodecylbenzenesulfonate, sodium lauryl sulfate It...

Embodiment 3

[0066] A tile anti-slip agent, comprising the following raw materials in parts by weight:

[0067]

[0068] Wherein, the particle size of the polymer foam material is 20 μm.

[0069] The polymer foaming material is a foaming resin doped with inorganic oxides.

[0070] The weight ratio of the foamed resin to the inorganic oxide is 20:2.

[0071] The inorganic oxide is titanium dioxide modified by silane coupling agent KH550 and maleic anhydride grafted polypropylene; the foaming resin is melamine formaldehyde resin.

[0072] The fluoride salt is made by mixing ammonium fluoride and ammonium bifluoride in a weight ratio of 4:1; the penetrating agent is made by mixing fatty alcohol polyoxyethylene ether and alkylphenol polyoxyethylene ether in a weight ratio of 1:5 .

[0073] The brightener is formed by mixing a nonionic surfactant and an anionic surfactant in a weight ratio of 2:8; the anionic surfactant is sodium dodecylbenzenesulfonate, sodium lauryl sulfate It is mixed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com