Bioactivity bracket and preparation method thereof

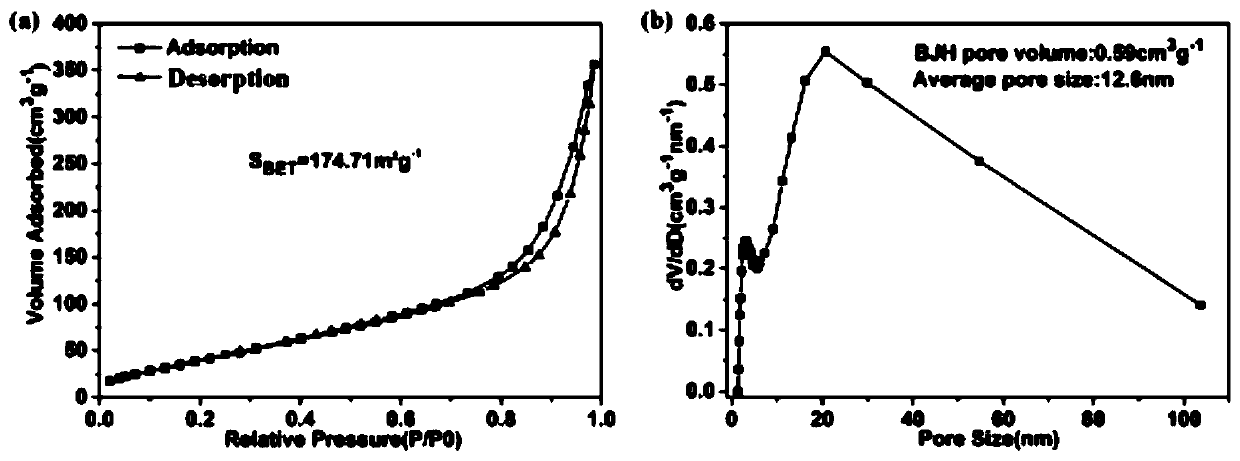

A bioactive, composite stent technology, applied in the field of bioactive stents and their preparation, achieves the effects of high pore volume and specific surface area, improving drug activity, and improving drug encapsulation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A method for preparing a bioactive scaffold, comprising the following steps:

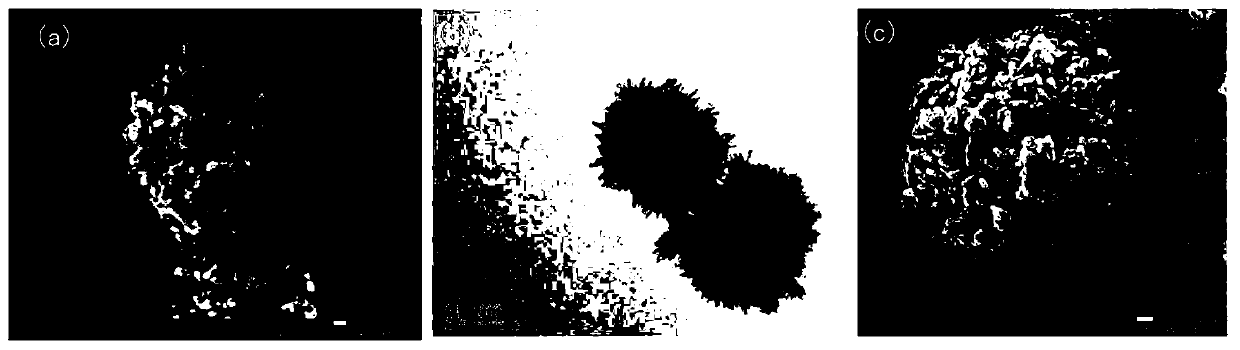

[0044] S1: Preparation of hollow mesoporous hydroxyapatite microspheres (MHA)

[0045] Add 1.963g creatine phosphate to 100mL distilled water to prepare A solution, add 1.225g calcium chloride dihydrate to 250mL distilled water to prepare B solution; take 10mL A solution and slowly drop into 30mL B solution, use 1mol / L Adjust the pH to about 10 with NaOH, and stir it with magnetic force for 30 minutes after the addition is complete; then move it to a microwave reactor, control the reaction temperature at 120°C, and microwave power at 5W, and continue to react for 30 minutes; then centrifuge, wash, and freeze-dry Get MHA.

[0046] S2: MHA surface functional modification and load bone morphogenetic protein

[0047] SS1: Soak MHA in absolute ethanol and ultrasonically disperse for 30min, then mix the dispersion with 20mmol / L γ-aminopropyltriethoxysilane (APS) ethanol solution at a volume ratio...

Embodiment 2

[0053] A method for preparing a bioactive scaffold, comprising the following steps:

[0054] S1: Preparation of hollow mesoporous hydroxyapatite microspheres (MHA)

[0055] Add 1.812g creatine phosphate to 100mL distilled water to prepare A solution, add 1.025g calcium chloride dihydrate to 250mL distilled water to prepare B solution; take 10mL A solution and slowly drop into 30mL B solution, use 1mol / L Adjust the pH to about 10 with NaOH, and stir it with magnetic force for 30 minutes after the addition is complete; then move it to a microwave reactor, control the reaction temperature to 150°C, and microwave power to 5W, and continue to react for 10 minutes; then centrifuge, wash, and freeze-dry Get MHA.

[0056] S2: MHA-loaded bone morphogenetic protein

[0057] Take 5 mg of the above-mentioned synthesized MHA, immerse in 50 mL of BMP-2 solution with a concentration of 0.2 μg / mL under aseptic conditions and oscillate at room temperature for equilibrium adsorption for 24 ho...

Embodiment 3

[0061] A method for preparing a bioactive scaffold, comprising the following steps:

[0062] S1: Preparation of hollow mesoporous hydroxyapatite microspheres (MHA)

[0063] Add 1.963g creatine phosphate to 100mL distilled water to prepare A solution, add 1.225g calcium chloride dihydrate to 250mL distilled water to prepare B solution; take 10mL A solution and slowly drop into 30mL B solution, use 1mol / L Adjust the pH to about 10 with NaOH, and stir the reaction for 30 minutes after the addition is complete; then move it to a microwave reactor, control the reaction temperature to 110°C, and the microwave power to 5W, and continue to react for 10 minutes; then centrifuge, wash, and freeze-dry Get MHA.

[0064] S2: MHA-loaded bone morphogenetic protein

[0065] Take 5 mg of the above-mentioned synthesized MHA, immerse in 50 mL of BMP-4 solution with a concentration of 0.3 μg / mL under aseptic conditions and oscillate at room temperature for equilibrium adsorption for 24 hours; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com