Sodium bismuth titanate-sodium tantanate solid solution ceramic material and preparation method and application thereof

A technology of sodium bismuth titanate and ceramic materials, which is applied in the direction of fixed capacitors, fixed capacitor dielectrics, fixed capacitor parts, etc., can solve problems such as the limitation of temperature stability range, and achieve excellent energy storage characteristics, excellent dielectric and energy storage performance, effect of uniform grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

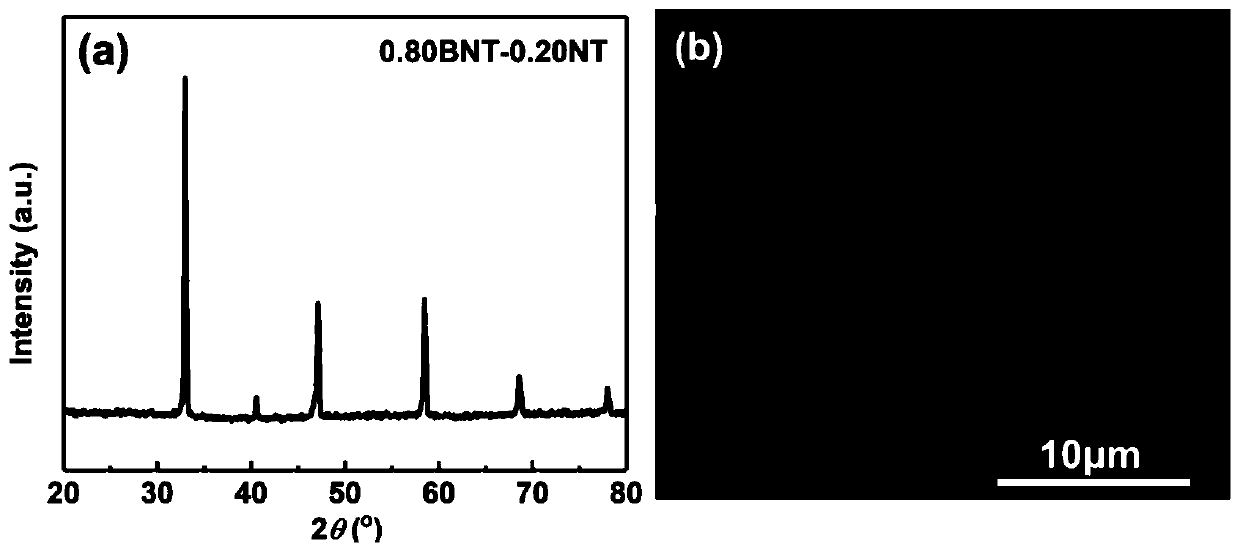

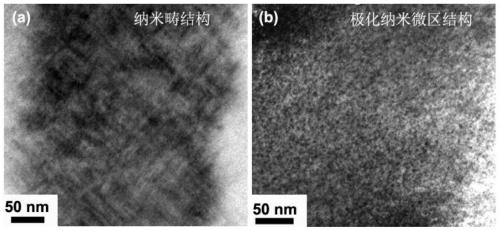

[0052] Preparation of 0.80BNT-0.20NT Ceramic Materials

[0053] According to 0.80Bi 0.5 Na 0.5 TiO 3 -0.20NaTaO 3 (0.80BNT-0.20NT) molar stoichiometric ratio Weigh the raw material Bi 2 o 3 , Na 2 CO 3 , Ta 2 o 5 and TiO 2 Mix evenly, put the prepared material into a nylon jar with absolute ethanol as the medium and zirconia balls as the balls for ball milling, and ball mill for 8 hours at a speed of 250r / min. Then the ball-milled slurry was dried at 80°C. The dried powder was passed through a 200-mesh sieve, placed in an alumina crucible, and pre-fired at 800°C for 3 hours to obtain a pre-fired powder. Put the calcined powder into a nylon tank with anhydrous ethanol as the medium and zirconia balls as the balls for ball milling, ball milling at a speed of 250r / min for 24h, and then dry at 80°C. After sieving the above-mentioned powder, add polyvinyl butyral (PVA) with a mass fraction of 1%, fully grind until the powder is granular, and obtain a powder with uniform...

Embodiment 2

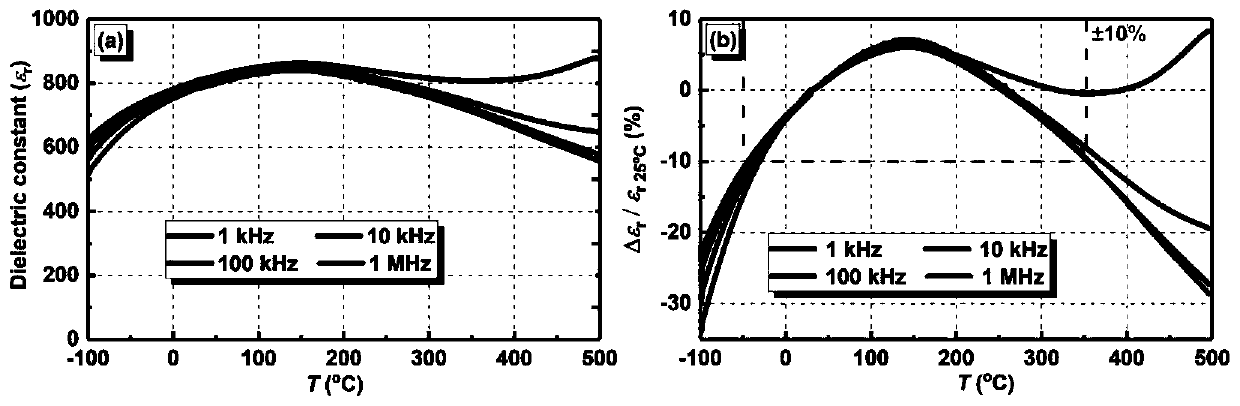

[0066] Compared with Example 1, the only difference is that x is 0.10. The prepared ceramics are still pure perovskite structure, without impurity phase, showing a pseudo-cubic phase structure, and the ceramics have no obvious defects, good crystallinity, uniform grain size and an average grain size of about 2-4 μm. However, the ceramic dielectric spectrum shows that its dielectric constant fluctuates (Δε r / ε r25℃ ) lower than 10% of the temperature range is only -15 ~ 80 ℃; at the same time, the hysteresis loop hysteresis is relatively large, although P max The value is larger, but at the same time P r The value is also large, and the anti-breakdown electric field is only 18kV / mm, resulting in its W D 2.15J / cm 3 , η is 56.5%.

Embodiment 3

[0068] Compared with Example 1, the only difference is that x is 0.30. The prepared ceramics are still pure perovskite structure, without impurity phase, showing a pseudo-cubic phase structure, and the ceramics have no obvious defects, good crystallinity, uniform grain size and an average grain size of about 2-4 μm. The temperature stability of its dielectric constant is good, and the dielectric constant is floating (Δε r / ε r25℃ ) lower than 10% of the temperature range is -60 ~ 308 ℃, the electric field against breakdown is as high as 38kV / mm, the hysteresis loop is thin and long, P rvalue is low, but its P max value is too low, causing W D decreased to 3.16J / cm 3 , η is higher at 82.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

| Energy storage density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com