Long-life lithium ion battery ternary positive electrode material, preparation method thereof and application

A technology for lithium-ion batteries and positive electrode materials, which is applied in the field of long-life lithium-ion battery ternary positive electrode materials and its preparation, can solve problems such as uneven and continuous coating layers, unsatisfactory improvement effects, and poor oxidation resistance stability. Surface protection and structural stability, easy mass production, good wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

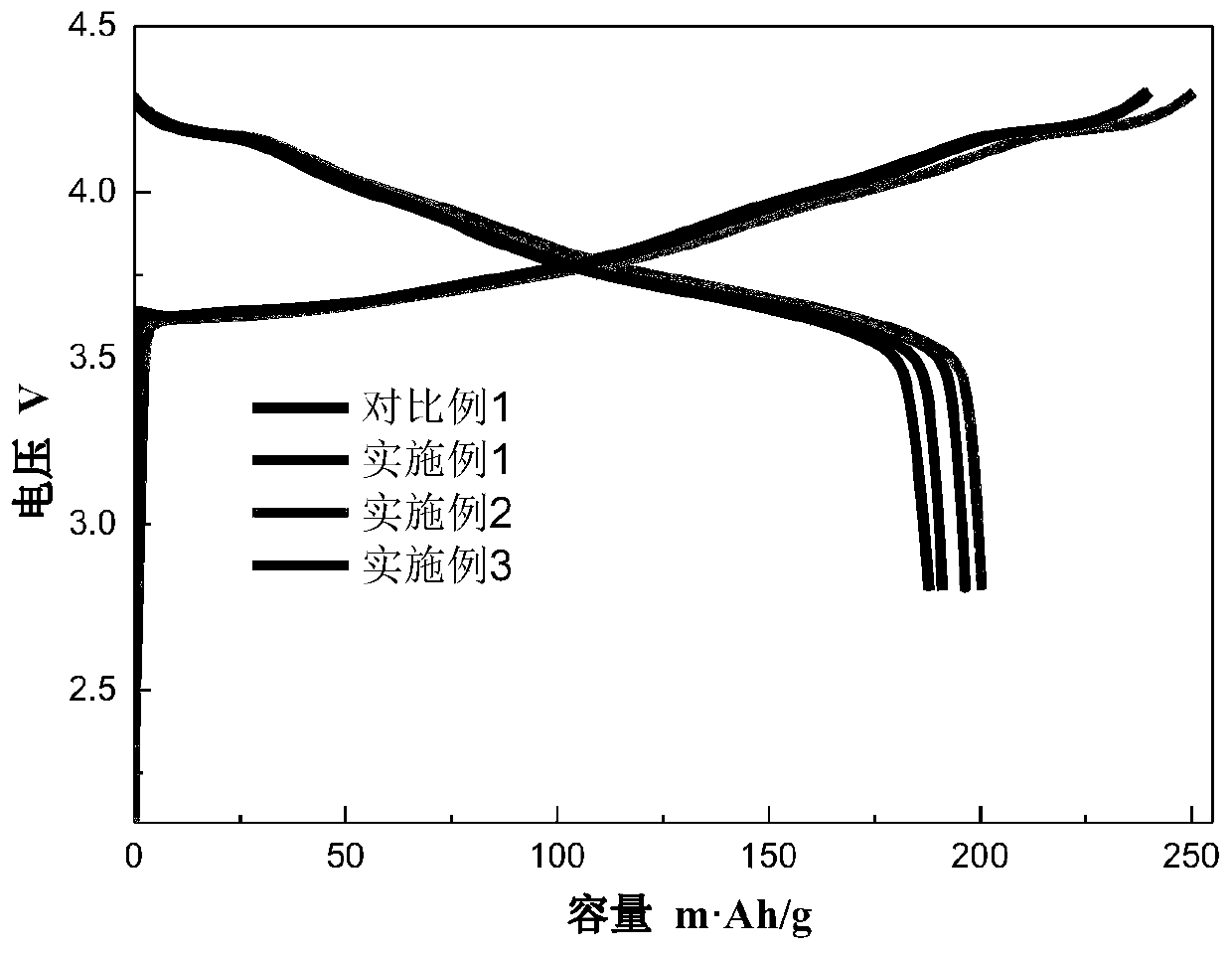

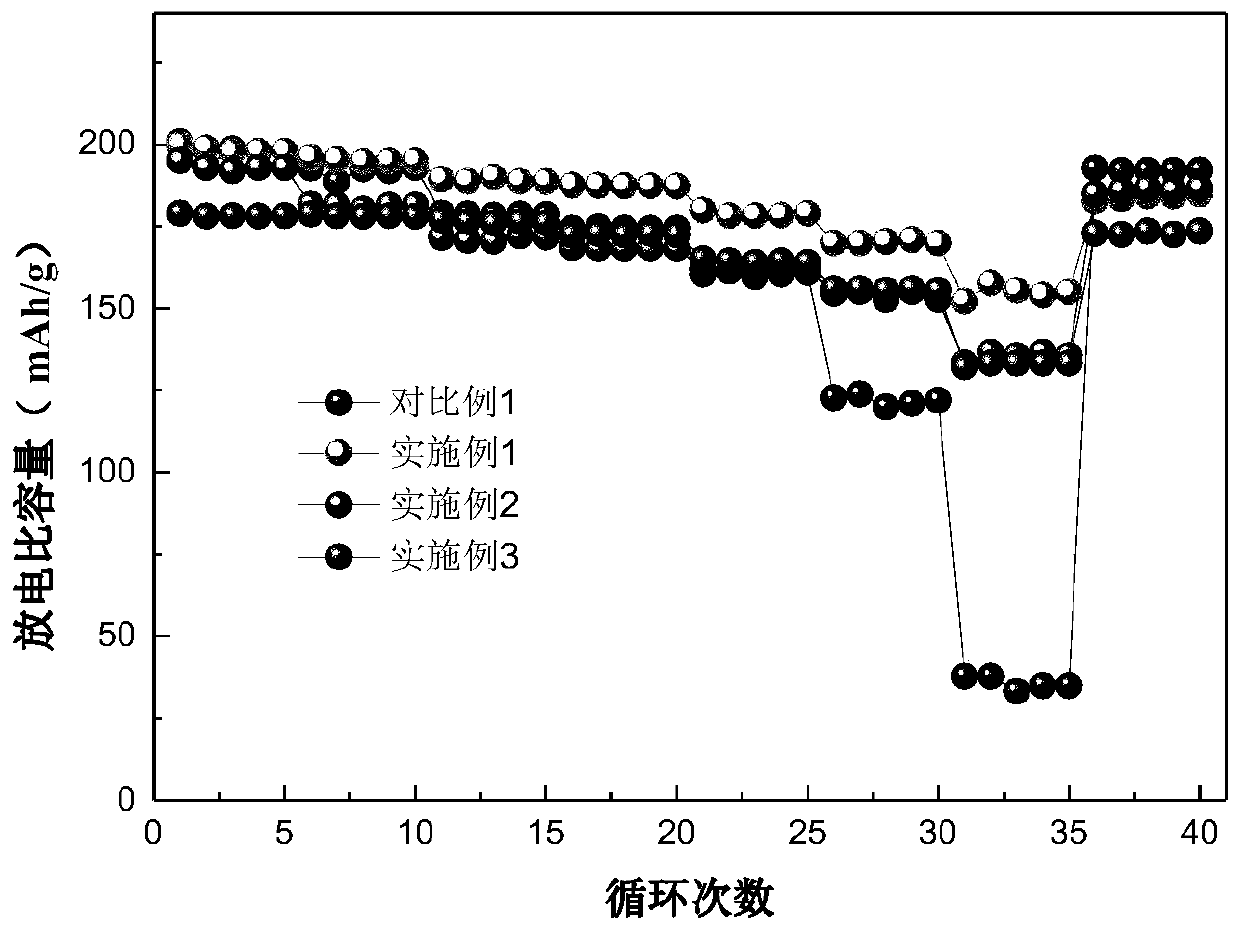

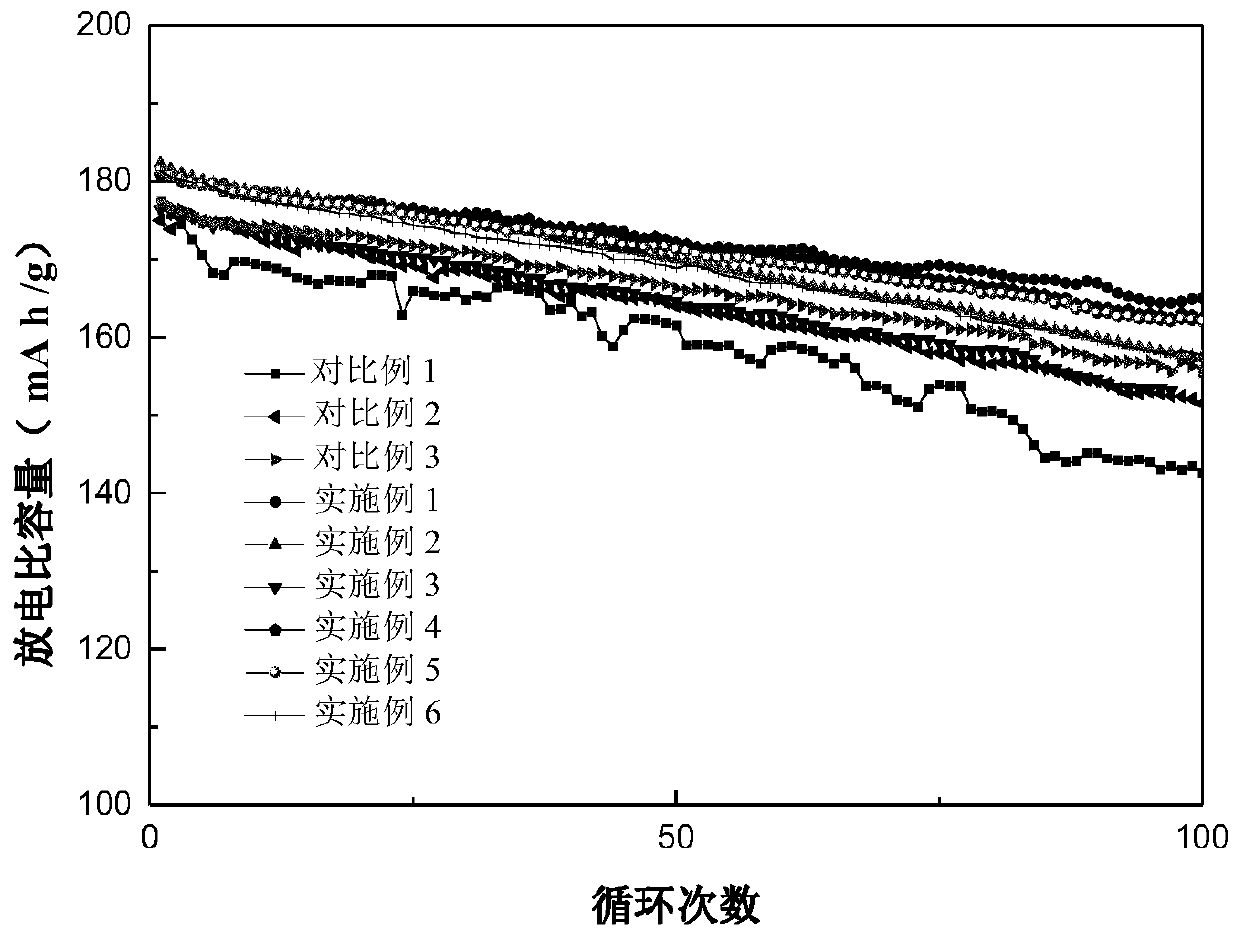

Embodiment 1

[0030] This example provides a single crystal LiNi 0.8 co 0.1 mn 0.1 o 2 The interface modification and preparation method specifically comprise the following steps:

[0031] (a) Heat and dissolve 0.05g of polymethyl methacrylate (PMMA) in 10g of acetone solvent (water removed by molecular sieve), and stir for 2h to form a uniform solution.

[0032] (b) Take 2g single crystal LiNi 0.8 co 0.1 mn 0.1 o 2 The active material is slowly added into the PMMA solution under the condition of 30° C., and kept stirring, and the solution is heated under the condition of constant stirring until the solvent is completely volatilized.

[0033] (c) Aging the powder product obtained in the above steps in a vacuum drying oven at a temperature controlled at 60° C. for 8 hours to obtain a ternary-coated positive electrode material with a PMMA coating amount of 2.5%.

[0034] The present invention also provides the application of this coated ternary positive electrode material in lithium-i...

Embodiment 2

[0036] This example provides a coating type single crystal LiNi 0.8 co 0.1 mn 0.1 o 2 The preparation method of the positive electrode material is basically the same as that in Example 1, except that 0.03 g of polyethyl methacrylate (PEMA) is dissolved in 10 g of toluene solvent for coating modification to obtain the PEMA coating amount It is 1.5% ternary coating cathode material.

Embodiment 3

[0038] This example provides a coating type single crystal LiNi 0.8 co 0.1 mn 0.1 o 2 The preparation method of the positive electrode material is basically the same as that in Example 1, except that 0.04 g of polyisoethyl methacrylate is dissolved in 10 g of toluene solvent for coating modification, and the coating amount is 2.0% Polyisoethyl methacrylate ternary coating cathode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com