Preparation method of metal-organic framework carbon nanotube hybrid desalination electrode

A technology of carbon nanotubes and organic frameworks, which is applied in the field of preparation of metal-organic framework carbon nanotube hybrid desalination electrodes, can solve the problems of polypyrrole nanotube preparation process complexity, low pore utilization rate, and low conductivity, and achieve The specific surface area and conductivity are controllable, easy to obtain, and the effect of improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

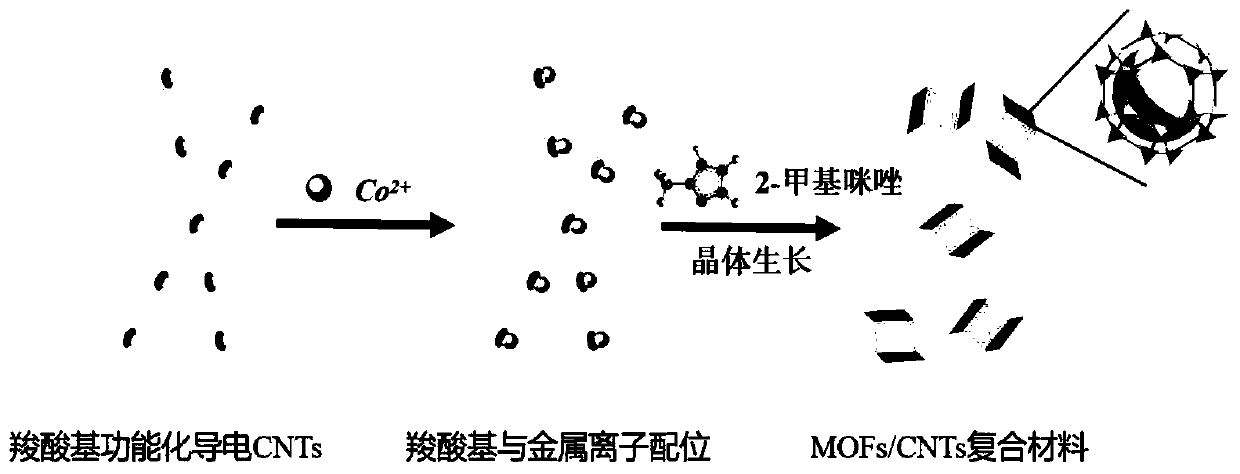

[0034]50 mg of carbon nanotubes were stirred in an ice bath at 200 rpm and added with concentrated nitric acid, left standing for 20 hours, centrifuged, and washed several times with distilled water to obtain carboxylated carbon nanotubes. Under ultrasonication, 50 mg of carboxylated carbon nanotubes were dispersed in 15 g of methanol solvent for 2 hours to obtain a carboxylated carbon nanotube solution; then 505 mg of cobalt nitrate was dispersed into the obtained carboxylated carbon nanotube solution under stirring for 1 hour to obtain A 20 mL carbon nanotube cobalt metal salt solution was formed. 350 mg of 2-methylimidazole was dissolved in 14 mL of methanol to form 15 mL of organic ligand solution; then the organic ligand solution was added dropwise to the carbon nanotube cobalt metal salt mixed solution for 1 hour under continuous stirring; left to stand for 24 hours After that, the precipitate was collected by centrifugation, washed thoroughly with methanol for several t...

Embodiment 2

[0040] 50 mg of carbon nanotubes were stirred in an ice bath at 300 rpm and added with concentrated nitric acid, left standing for 20 hours, and washed with distilled water for several times after centrifugation to obtain carboxylated carbon nanotubes. 50 mg of carboxylated carbon nanotubes were dispersed in 20 g of methanol solvent under sonication for 1 hour; then 750 mg of cobalt oxalate was dispersed into the resulting carboxylated carbon nanotube solution by sonication for 1 hour to form 21 ml of carbon nanotube cobalt metal salt solution. 800 mg of hexahydroxytriphenyl was dissolved in 20 mL of dimethylformamide to form 21 mL of the organic ligand solution; then the organic ligand solution was added dropwise to the carbon nanotube cobalt metal salt mixed solution for 1.5 hours with constant stirring; let stand After 24 h, the precipitate was collected by centrifugation, washed thoroughly with distilled water several times, and finally dried at 70 °C for 24 h to obtain th...

Embodiment 3

[0044] Add concentrated nitric acid to 50 mg of carbon nanotubes with stirring in an ice bath at 250 rpm, let stand for 20 hours, centrifuge, and wash with distilled water for several times to obtain carboxylated carbon nanotubes. 50 mg of carboxylated carbon nanotubes were dispersed in 25 g of methanol solvent under sonication for 1 hour; then 750 mg of cobalt sulfate was dispersed into the resulting carboxylated carbon nanotube solution by sonication for 0.5 h to form 25 mL of carbon nanotube cobalt metal salt solution. Dissolve 1.25 g of terephthalic acid in 25 mL of methanol to form 26 mL of an organic ligand solution; then add the prepared organic ligand solution dropwise to the carbon nanotube cobalt metal salt mixed solution prepared above under continuous stirring 1 hour; after standing for 24 hours, the precipitate was collected by centrifugation, washed thoroughly with ethanol for several times, and finally dried at 80 °C for 24 hours to obtain the MOF / CNT hybrid mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com