Saline-alkali land soil desalting agent and preparation method thereof

A technology of saline-alkali land and soil moisture retaining agent, applied in the field of saline-alkali land soil improvement, can solve the problems of inhibiting crop growth and development, prone to salt return, waste of land resources, etc., and achieves reduction of water evaporation rate, extension of soil action time, and improvement of air permeability and water permeability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

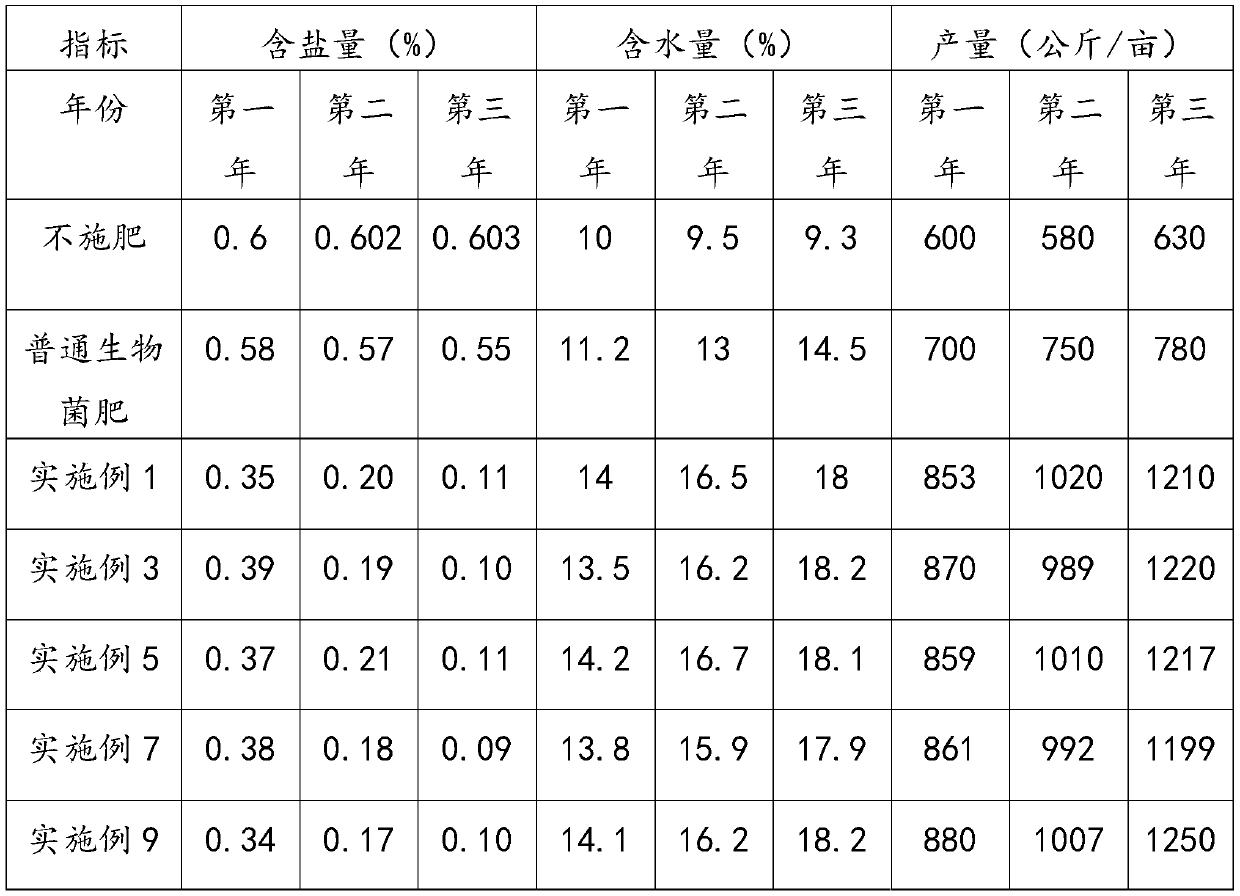

Examples

Embodiment 1

[0025] A soil desalination agent for saline-alkali land, comprising the following parts by weight: 20 parts of mineral humus superfine powder, 50 parts of animal manure, 20 parts of crop straw, 0.04 parts of fertilizer decomposing agent, 5 parts of calcium chloride, and 0.5 parts of salt-dissolving bacteria 1 part, 1 part of soil moisture retention agent.

[0026] The raw material of the ore source humus ultrafine powder is lignite, and the organic matter and water content in the lignite are 85%.

[0027] The water content of the animal manure is 77%, and the animal manure is cow dung; the crop straw is peanut husk powder and rice husk powder, and the weight ratio of the peanut husk powder and rice husk powder is 1:1.

[0028] The composition and mass ratio of the salt-dissolving bacteria are: saprophytic bacteria: nitrifying bacteria: sulfur bacteria is 10:0.4:0.4.

[0029] The saprophytic bacterium is Bacillus subtilis.

[0030] The soil moisture retention agent is a starc...

Embodiment 2

[0032] The preparation method of the saline-alkali land soil desalination agent of embodiment 1, concrete steps are as follows:

[0033] A: Mineral source humus is crushed by the model 200---1500L3.QH high-speed ultrafine grinder produced by Changsha Qinghe General Machinery Equipment Co., Ltd., and then passed through the AF050 series airflow classifier produced by Weifang Jingjing Powder Engineering Equipment Co., Ltd. The adjustment of the mineral source humus ultrafine powder with a particle size of 1 μm is obtained. The crushing process must control the grinding temperature and cannot exceed 80 ° C;

[0034] B: The crop straw is crushed by a yzz165-27 crop straw grinder manufactured by Jinan Yuezhen Machinery Co., Ltd., and then mixed evenly with the animal manure and fertilizer decomposing agent. The fertilizer decomposing agent is made of Weifang The fertilizer decomposing agent produced by Yihao Biotechnology Co., Ltd. has a bacterial count of 10 billion CFU / g. After c...

Embodiment 3

[0039] A soil desalination agent for saline-alkali land, comprising the following parts by weight: 25 parts of mineral humus superfine powder, 50 parts of animal manure, 25 parts of crop straw, 0.05 part of fertilizer decomposing agent, 0.8 part of salt-dissolving bacteria, and 5 parts of calcium chloride part, 1.5 parts of soil moisture retention agent.

[0040] The raw material of the ore source humus ultrafine powder is lignite, and the organic matter and water content in the lignite are 85%.

[0041] The water content of the animal manure is 77%, and the animal manure is cow dung; the crop straw is peanut husk powder and rice husk powder, and the weight ratio of the peanut husk powder and rice husk powder is 1:1.

[0042] The composition and mass ratio of the salt-dissolving bacteria are: saprophytic bacteria: nitrifying bacteria: sulfur bacteria is 10:0.4:0.4.

[0043] The saprophytic bacteria are Bacillus subtilis and Bacillus megaterium, and the number ratio of Bacillu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com