A kind of organosilicon modified zinc acrylate/zinc pyrithione composite antifouling coating and its preparation method and application

A technology of zinc pyrithione and zinc acrylate, applied in antifouling/underwater coatings, coatings, paints containing biocide, etc., can solve problems such as unstable antifouling performance, polluting the atmosphere, and destroying marine ecology, achieving Excellent antifouling and antibacterial performance, low VOC emission, and strong inhibitory effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

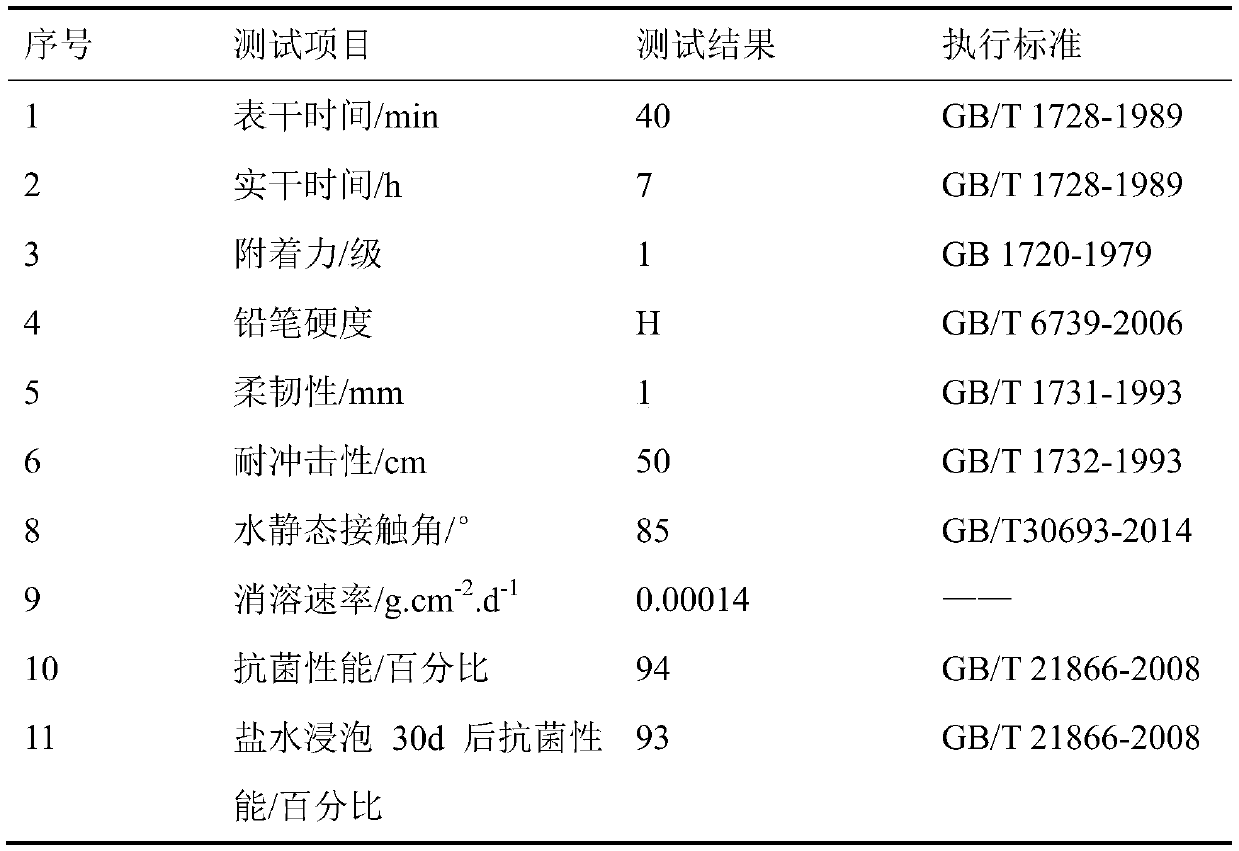

Embodiment 1

[0023] In the present embodiment, the organosilicon-modified zinc acrylate / zinc pyrithione composite antifouling coating comprises the following steps in terms of mass:

[0024] 1. The preparation of organosilicon-modified zinc acrylate emulsion: wash the acrylate monomer 3 times with 5% NaOH solution and deionized water successively to obtain the refined monomer; weigh 19g methyl methacrylate (Sinopharm Group Chemical Reagent Co., Ltd. , AR), 14.68g n-butyl acrylate (Sinopharm Chemical Reagent Co., Ltd., AR) were mixed uniformly to obtain a monomer mixture, and 1.73g sodium lauryl sulfate (Sinopharm Chemical Reagent Co., Ltd., CP) was weighed and dissolved in 5g deionized water (self-made) obtains emulsifying agent solution, takes by weighing 0.17g potassium persulfate (Sinopharm Group Chemical Reagent Co., Ltd., AR) and is dissolved in 2.5g deionized water to obtain initiator aqueous solution; Get 2 / 3 monomer mixed solution , 1 / 2 of the emulsifier solution, 0.43g of acrylic ...

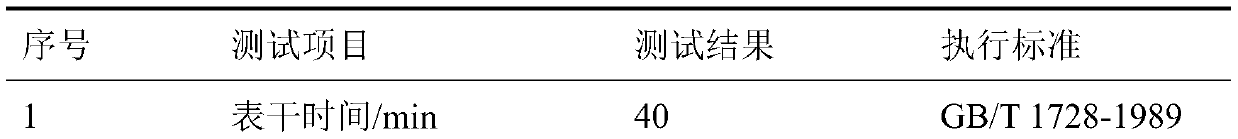

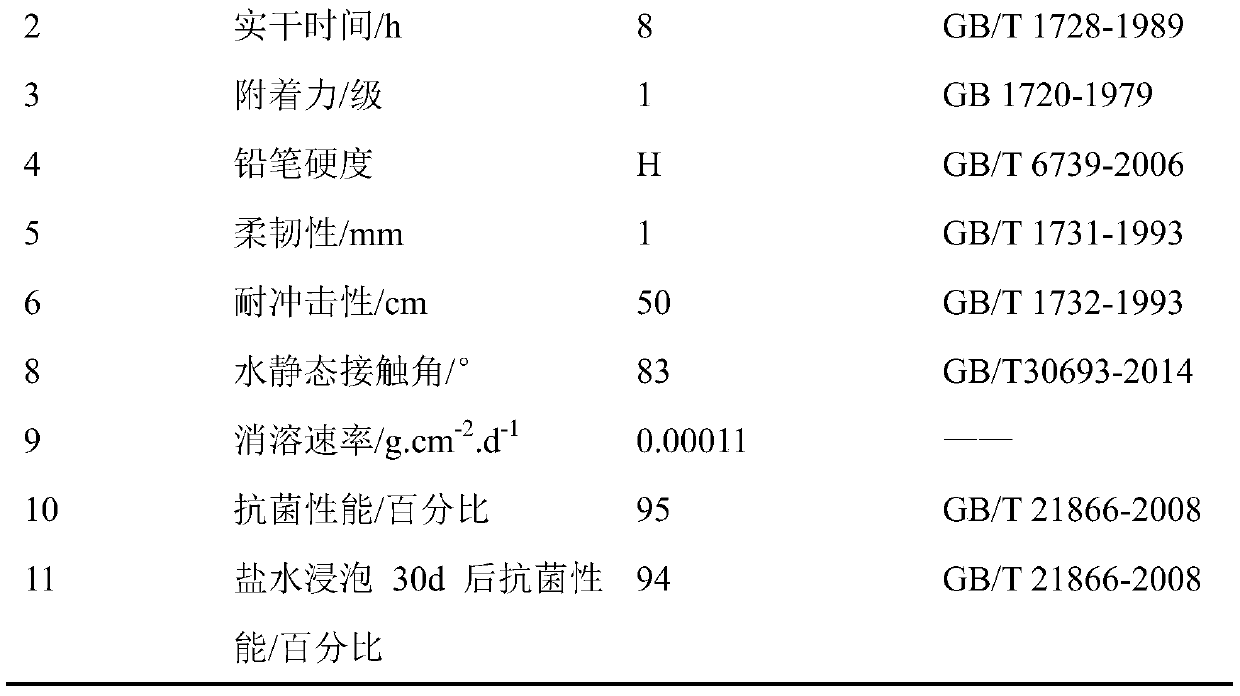

Embodiment 2

[0031] In the present embodiment, the organosilicon-modified zinc acrylate / zinc pyrithione composite antifouling coating comprises the following steps in terms of mass:

[0032] 1. Preparation of organosilicon-modified zinc acrylate emulsion: wash acrylate monomers with 5% NaOH solution and deionized water for 3 times to obtain refined monomers; weigh 18.6g methyl methacrylate, 18.6g n-butyl acrylate ester, 6.43 glycidyl methacrylate mixed evenly to obtain a monomer mixture, weighed 1.50g polyethylene glycol octylphenyl ether dissolved in 5g deionized water to obtain an emulsifier solution, weighed 0.17g ammonium persulfate dissolved in 2.5g deionized water to obtain initiator aqueous solution; take 2 / 3 of the monomer mixture, 1 / 2 of the emulsifier solution, 0.7g of acrylic acid and 24.5g of deionized water, mix them and pre-emulsify for 40min with magnetic stirring to obtain a pre-emulsion ; Take 1 / 3 of the pre-emulsion and add 1.48g of dodecyltrimethoxysilane, magnetically s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tack-free time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com