Acrylic fiber-based lithium-sulfur battery interlayer material and preparation method thereof

A technology for interlayer materials and sulfur batteries, which is applied to secondary batteries, battery pack components, circuits, etc., can solve the problems of difficult electrochemical reactions, poor LiPS capture and conversion efficiency, and poor performance, and achieves a simple preparation method. , The preparation process is simple and green

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A method for preparing a lithium-sulfur battery interlayer material based on acrylic yarn as a carbon source with excimer ultraviolet lamp irradiation modification of ZnO, the specific steps of the method are as follows:

[0039](1) Accurately weigh the acrylic fiber dissolved in N-N dimethylformamide (DMF) with an analytical balance, and the total concentration of solute is 10%. Stir at room temperature for 48 h, then raise the temperature to 85° C., and stir for 2 h to obtain a uniform and stable electrospinning solution.

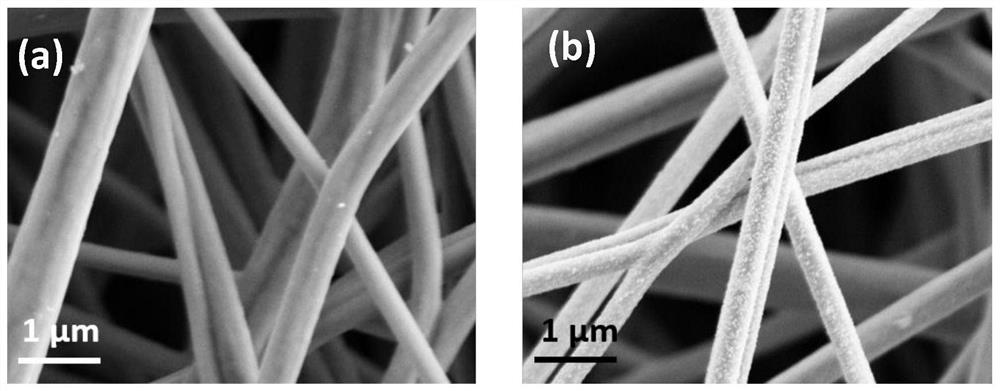

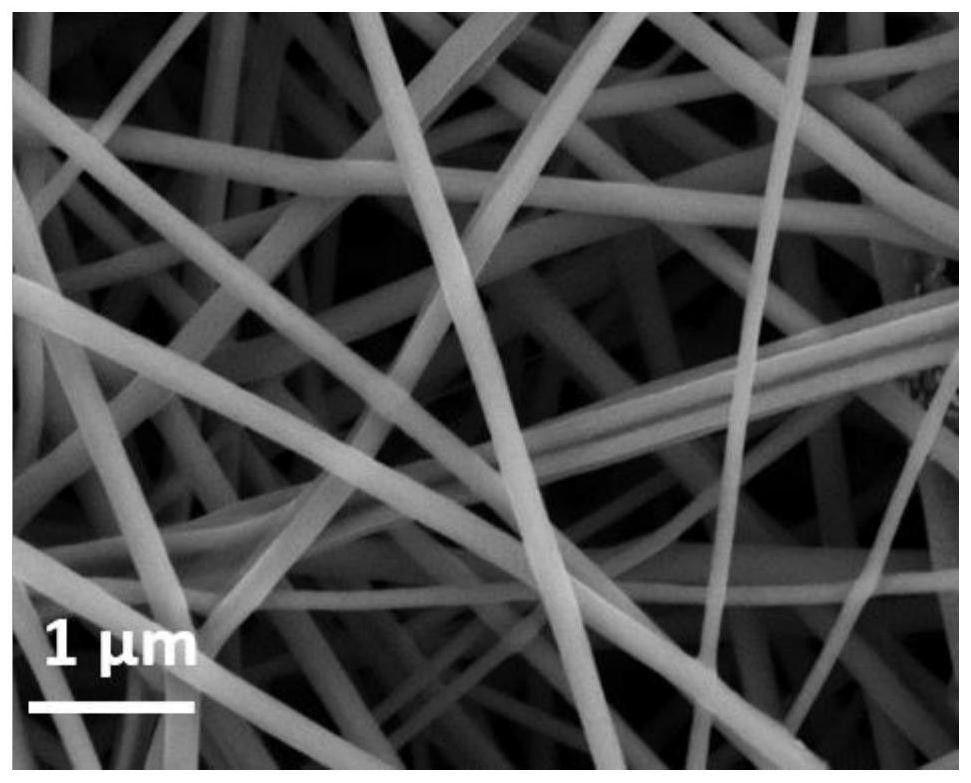

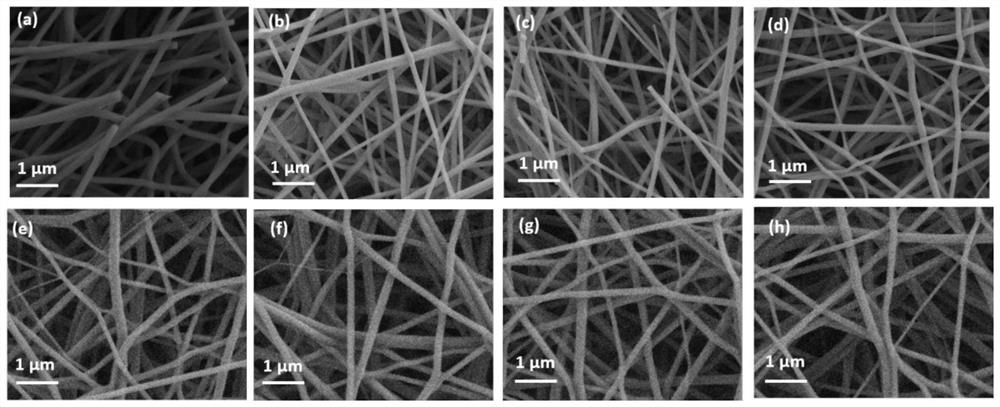

[0040] (2) Electrospinning equipment was used to prepare nanofiber membranes, the spinning voltage was 10 kV, the receiving distance was 20 cm, and the air humidity was 50%. The evenly stirred spinning solution was electrospun.

[0041] (3) High-temperature carbonization: Pre-oxidize at 190°C for 90 minutes, and then carbonize at 800°C for 3 hours. Carbonization needs to be in an argon atmosphere to obtain a carbon nanofiber film with acrylic fiber...

Embodiment 2

[0045] A method for preparing a lithium-sulfur battery interlayer material based on acrylic yarn as a carbon source with excimer ultraviolet lamp irradiation modification of ZnO, the specific steps of the method are as follows:

[0046] (1) Accurately weigh the acrylic fiber dissolved in N-N dimethylformamide (DMF) with an analytical balance, and the total concentration of solute is 10%. Stir at room temperature for 48 h, then raise the temperature to 85° C., and stir for 2 h to obtain a uniform and stable electrospinning solution.

[0047] (2) The nanofiber membrane was prepared by electrospinning equipment, the spinning voltage was 10 kV, the receiving distance was 20 cm, and the air humidity was 50%.

[0048] (3) High-temperature carbonization: Pre-oxidize at 190°C for 90 minutes, and then carbonize at 800°C for 3 hours. Carbonization needs to be in an argon atmosphere to obtain a carbon nanofiber film with acrylic fiber as the carbon source.

[0049] (4) Put the carbon na...

Embodiment 3

[0052] A method for preparing a lithium-sulfur battery interlayer material based on acrylic yarn as a carbon source with excimer ultraviolet lamp irradiation modification of ZnO, the specific steps of the method are as follows:

[0053] (1) Accurately weigh the acrylic fiber dissolved in N-N dimethylformamide (DMF) with an analytical balance, and the total concentration of solute is 10%. Stir at room temperature for 48 h, then raise the temperature to 85° C., and stir for 2 h to obtain a uniform and stable electrospinning solution.

[0054] (2) The nanofiber membrane was prepared by electrospinning equipment, the spinning voltage was 10 kV, the receiving distance was 20 cm, and the air humidity was 50%.

[0055] (3) High-temperature carbonization: Pre-oxidize at 190°C for 90 minutes, and then carbonize at 800°C for 3 hours. Carbonization needs to be in an argon atmosphere to obtain a carbon nanofiber film with acrylic fiber as the carbon source.

[0056] (4) Put the carbon na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com