Ammonia gas molecularly-imprinted adsorbent for separating gas mixture produced in aerobic composting of sludge and recovering ammonia gas, and preparation method thereof

A molecularly imprinted and adsorbent technology, applied in the field of ammonia molecularly imprinted adsorbent and its preparation, can solve the problems of unresearched ammonia separation in mixed components, unknown ammonia adsorption and separation effect, unknown ammonia dynamic adsorption amount, etc. , to achieve good adsorption selectivity, no need for high temperature and high pressure, and easy to obtain effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

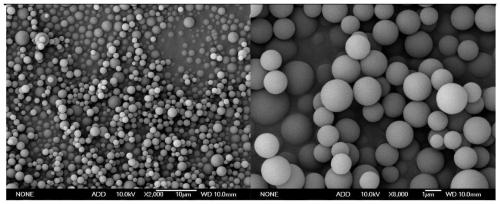

[0044] Example 1, Preparation of Ammonia Molecularly Imprinted Adsorbent

[0045] Add 48.66 μl of ammonia water and 219.84 μl of methacrylic acid functional monomer into a three-neck flask containing 60ml of toluene, pre-mix for 10min with the assistance of a magnetic stirrer, then add 1.22ml of ethylene glycol dimethacrylate crosslinking agent and 10mg of azobisisobutyronitrile initiator, stirred and mixed. After the reagents are mixed evenly, open the nitrogen bottle, pass nitrogen gas into the three-necked flask, and exhaust for 10 minutes. The three-necked flask exhausted of air was sealed and then heated continuously for 12 hours in a water bath at 60° C. to carry out free radical polymerization. After the reaction was completed, the suspension was removed, and the precipitated substance was repeatedly washed with deionized water, ultrasonically for half an hour, until the ammonium ion was no longer detected in the filtrate (the adsorption performance test method in Exam...

Embodiment 2

[0047] Example 2. Adsorption Performance Test of Ammonia Molecularly Imprinted Adsorbent

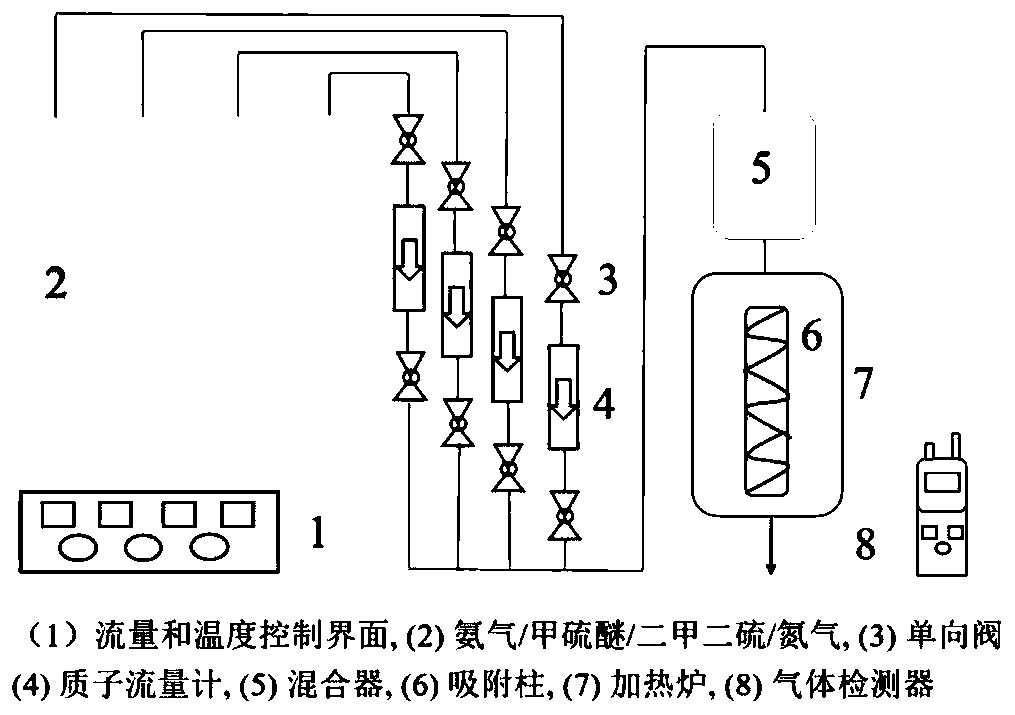

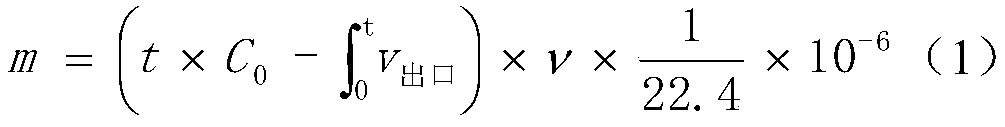

[0048] (1) Take 0.2 g of the ammonia molecularly imprinted adsorbent prepared in Example 1 and place it on the adsorption column of the dynamic adsorption device to carry out the ammonia dynamic adsorption experiment (the schematic diagram of the dynamic adsorption device is as follows figure 2 shown), the adsorption conditions and ammonia adsorption capacity are shown in Table 1.

[0049] (2) The maximum discharge ratio of ammonia, methyl sulfide and dimethyl disulfide detected by sludge aerobic composting is about 10:1:1, which is the ratio of the intake concentration of the mixed gas. The selective adsorption test of ammonia gas to methyl sulfide and dimethyl disulfide (ammonia adsorption capacity / methyl sulfide or dimethyl disulfide adsorption capacity) is shown in Table 1.

[0050] The adsorption capacity of ammonia molecularly imprinted polymers on ammonia / methyl sulfide / dimethyl...

Embodiment 3

[0069] Investigate the ammonia adsorption capacity of the product obtained by hydrolysis (step 5) under different acid-base conditions, as shown in table 3:

[0070] table 3

[0071] Adsorbents prepared in different pH solutions Adsorption capacity (mmol / g) pH=13.5 alkaline solution 0.03 pH=12 alkaline solution 0.29 pH=2 acid solution 0.71 pH=0.5 acid solution 7.54 Not hydrolyzed 0.42

[0072] Among them, the detection conditions of the adsorption amount are: the gas flow rate is 200ml / min, the temperature is 20°C, the ammonia gas inlet concentration is 100ppm, and the relative humidity is 0%.

[0073] It can be seen from Table 3 that the ammonia adsorption capacity of the prepared adsorbent varies greatly when hydrolyzed under different pH conditions, and the ammonia adsorption capacity of the adsorbent prepared by hydrolysis in an acid solution with a pH of 0.5 is the highest, up to 7.54mmol / g, therefore, the ammonia molecularl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com