A kind of low silicon sapo-34 molecular sieve and its preparation method and application

A molecular sieve, silica sol technology, applied in the direction of molecular sieve and alkali exchange phosphate, molecular sieve catalyst, molecular sieve characteristic silicoaluminophosphate, etc., can solve the problem of pure phase SAPO-34 molecular sieve difficult to directly synthesize and so on, achieve the inhibition of heterocrystalline Generation, usage reduction, grain size reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

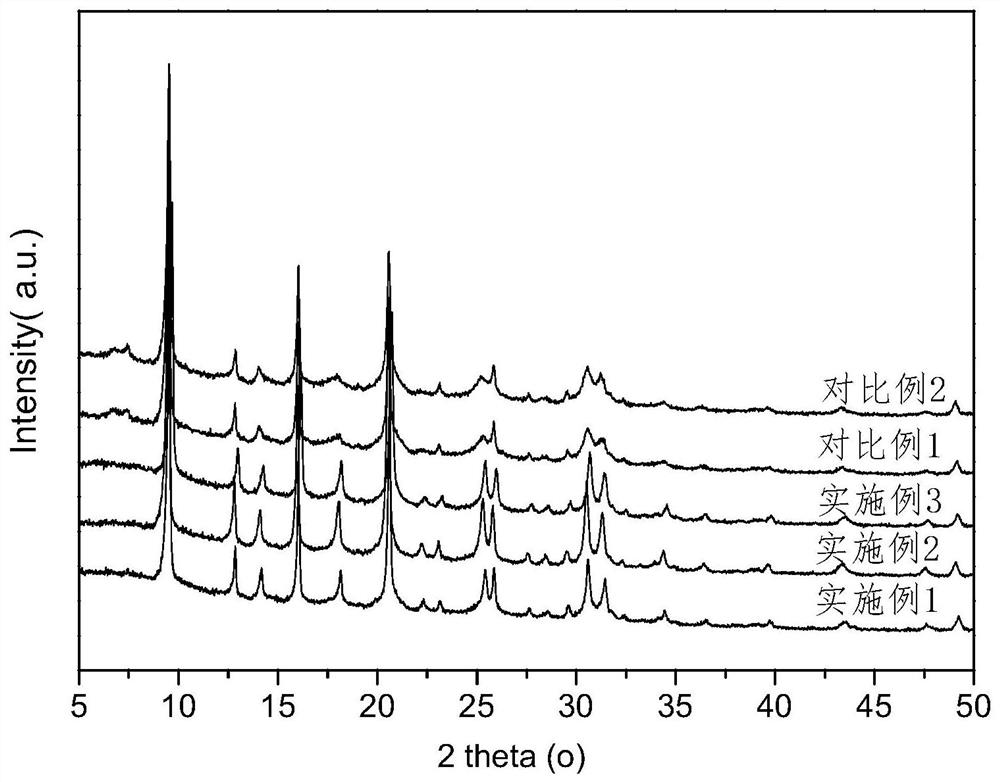

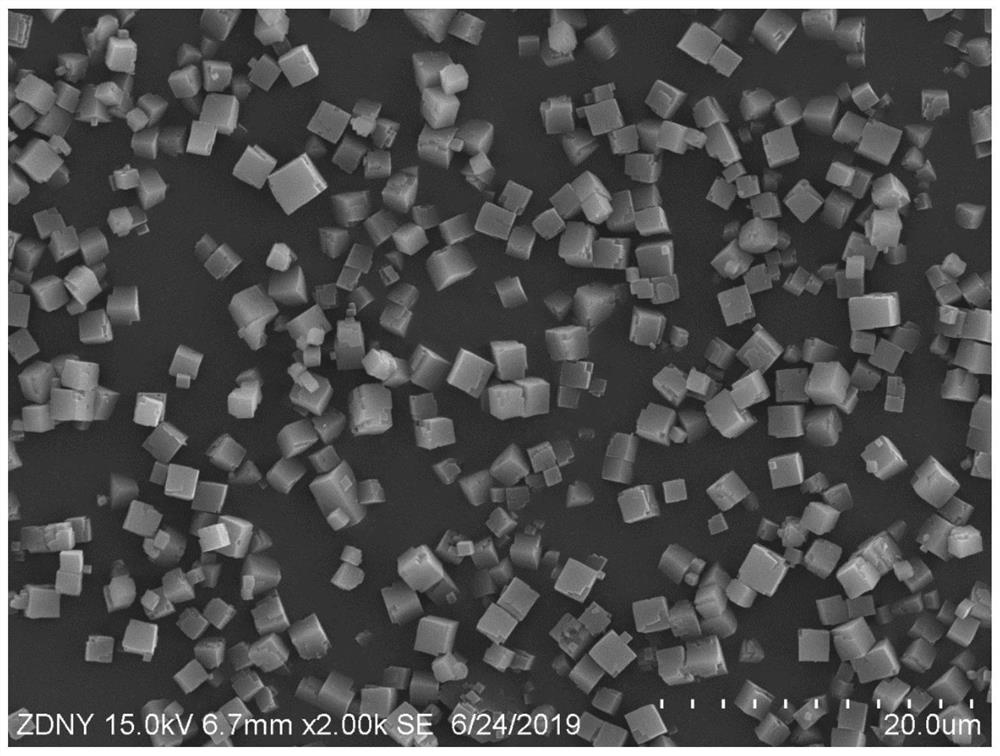

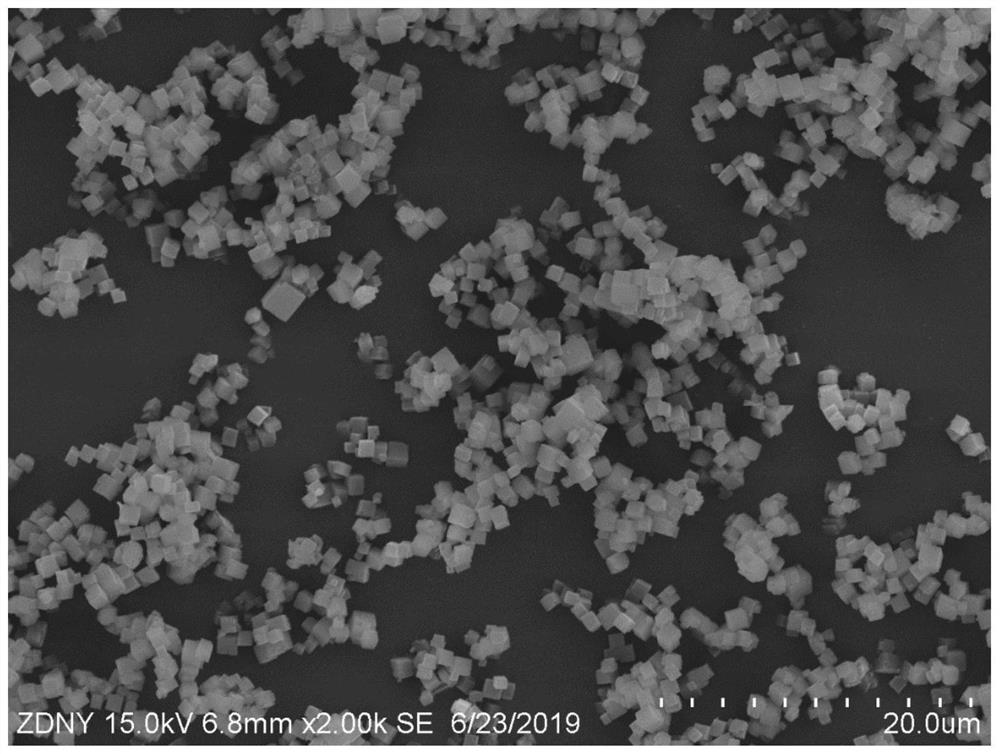

Embodiment 1

[0024] Disperse 25g of pseudo-boehmite, 1.7g of ethyl silicate and SAPO-34 seed crystals into an appropriate amount of water, add 16g of triethylamine, 16g of diisopropylamine and 7g of tetraethylammonium hydroxide mixed template and stir for 10min to Disperse evenly, slowly add 40g of phosphorus source to the above mixture, after the reaction is sufficient, add 1.8g of silica sol to form a uniform gel, and transfer it to a stainless steel reactor, aging at room temperature for 1 hour, and raising the temperature at a rate of 1°C / min to Crystallize at 170°C for 12 hours, then heat up to 200°C for 10 hours in 90 minutes. After the crystallization, the mixture was cooled to room temperature, and the crystallized product was separated and washed repeatedly with deionized water until the filter cake was neutral. The molecular sieve crystallized product was dried in an oven at 110°C for 8 hours to obtain the original powder of SAPO-34 molecular sieve, which was calcined at 300°C fo...

Embodiment 2

[0030] Disperse 25g of pseudo-boehmite, 3.4g of ethyl silicate and SAPO-34 seed crystals into an appropriate amount of water, add 16g of triethylamine, 16g of diisopropylamine and 7g of tetraethylammonium hydroxide mixed template and stir for 10min to Disperse evenly, slowly add 40g of phosphorus source to the above mixture, after the reaction is sufficient, add 3.6g of silica sol to form a uniform gel, and transfer it to a stainless steel reactor, aging at room temperature for 1 hour, and raising the temperature at a rate of 0.5°C / min to Crystallize at 170°C for 10 hours, then heat up to 200°C for 8 hours in 90 minutes. After the crystallization, the mixture was cooled to room temperature, and the crystallized product was separated and washed repeatedly with deionized water until the filter cake was neutral. The molecular sieve crystallized product was dried in an oven at 110°C for 8 hours to obtain the original powder of SAPO-34 molecular sieve, which was calcined at 300°C f...

Embodiment 3

[0032] Disperse 25g of pseudo-boehmite, 4.4g of ethyl silicate and SAPO-34 seed crystals into an appropriate amount of water, add 32g of triethylamine and 7g of tetraethylammonium hydroxide mixed template agent and stir for 10min until the dispersion is uniform. Slowly add 40g of phosphorus source to the mixture. After the reaction is sufficient, add 3.6g of silica sol to form a uniform gel, and transfer it to a stainless steel reaction kettle, aging at room temperature for 2 hours, and crystallize at 170°C at a heating rate of 0.3°C / min. After 90 minutes, the temperature was raised to 200°C for 12 hours of crystallization. After the crystallization, the mixture was cooled to room temperature, and the crystallized product was separated and washed repeatedly with deionized water until the filter cake was neutral. The molecular sieve crystallized product was dried in an oven at 110°C for 8 hours to obtain the original powder of SAPO-34 molecular sieve, which was calcined at 300°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com