Emulsified oil compound agent and preparation method, emulsified oil prepared therefrom and application thereof

A technology of emulsified oil and compounding agent, which is applied in chemical instruments and methods, petroleum industry, lubricating compositions, etc., can solve the problems of high cost and achieve the effects of long time, quality improvement, emulsification performance and stability performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] According to the mass ratio of ancient oil: oleic acid triethanolamine soap: water=6:1:3, the three are compounded to obtain the emulsifier of the present invention, and the more commonly used naphthenic acid soap is selected as a comparison, and the two are added respectively 9 times the mass of water is made into 10% aqueous solution, and the stability of each aqueous solution is measured. The results are shown in the table below:

[0049] Table 1

[0050] name Aqueous solution stability Sodium naphthenate soap solution Oil analysis 0.3%; soap analysis 0.2% The aqueous solution of the compounded emulsifier of the present invention Oil separation

[0051] As can be seen from the above table, the emulsifier obtained by compounding the three of the present invention is much more stable than the aqueous solution of naphthenic acid soap.

Embodiment 2

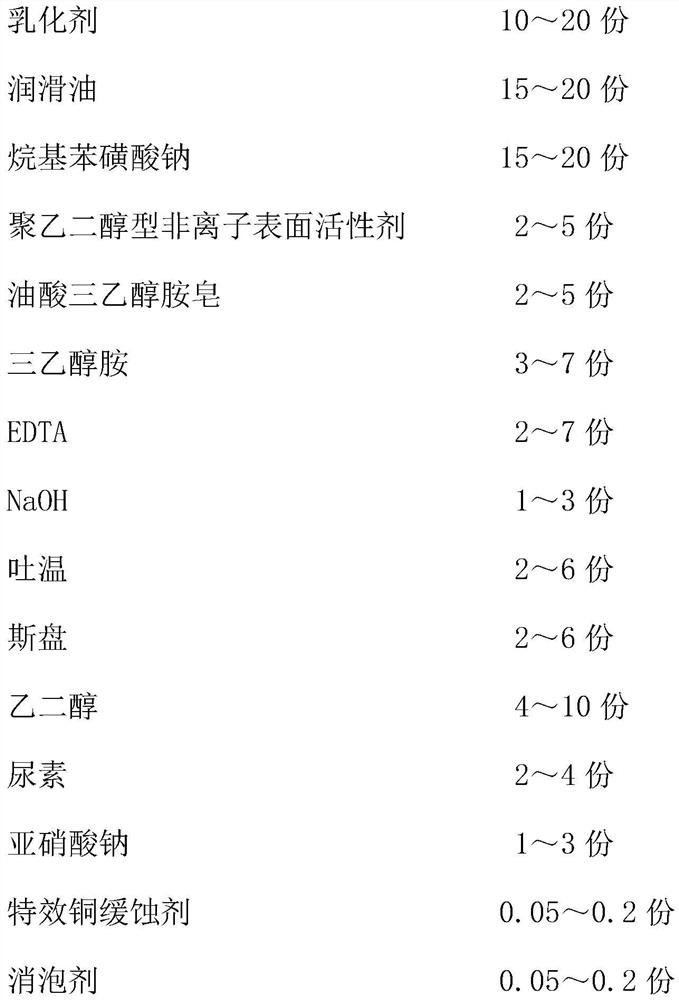

[0053] (1) prepare emulsified oil compound, the emulsified oil compound of the present embodiment is made by following raw material by weight:

[0054]

[0055]

[0056] The emulsifier is made of the following three raw materials in a mass ratio of ancient oil: oleic acid triethanolamine soap: water = 6:1:3.

[0057] The preparation method of the emulsified oil compound agent of the present embodiment is through the following steps:

[0058] 1) prepare an emulsifier in the ratio of Swire oil: oleic acid triethanolamine soap: water=6:1:3 by mass ratio;

[0059] 2) Mix and stir the prepared emulsifier, OP-10 and sodium alkylbenzene sulfonate for 20 minutes at room temperature until the solution is clear;

[0060] 3) Add lubricating oil (this embodiment is mechanical oil) and triethanolamine, stir evenly, and stir at room temperature for 20 minutes until the solution is clear;

[0061] 4) Add EDTA, NaOH, and Tween and stir evenly, then add triethanolamine oleic acid soap ...

Embodiment 3

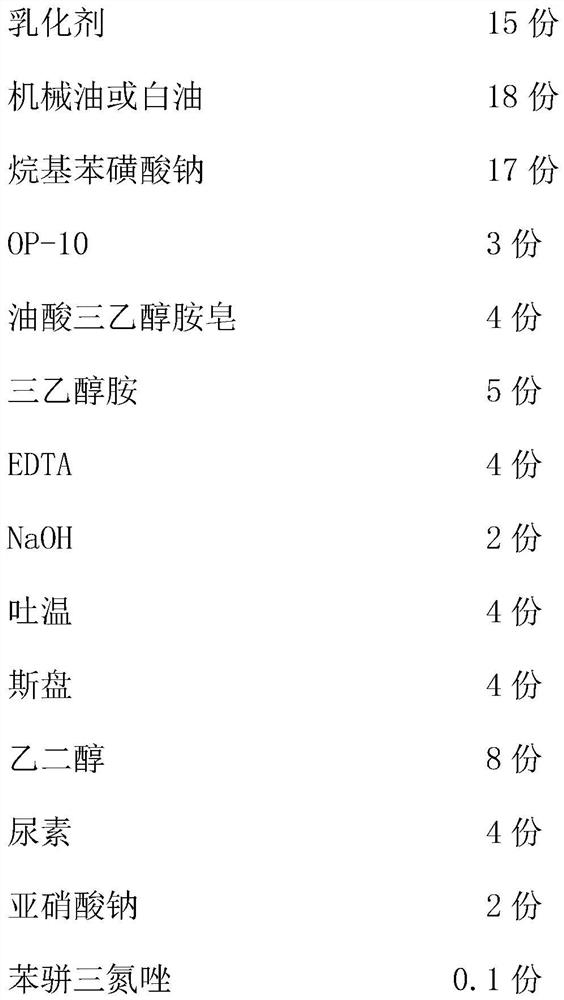

[0074] (1) prepare emulsified oil compound, the emulsified oil compound of the present embodiment is made by following raw material by weight:

[0075]

[0076] The emulsifier is composed of the following three raw materials: Swire oil: oleic acid triethanolamine soap: water=6:1:3 by mass ratio.

[0077] The preparation method of the emulsified oil compound agent of this embodiment is the same as that of Embodiment 2.

[0078] (2) Prepare emulsified oil: add the emulsified oil compound prepared in this example and mechanical oil into the container according to the mass ratio of 1:2, and then stir at room temperature for about 30 minutes until uniform to obtain the oil base Emulsified oil products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com