Closed isocyanate curing agent, preparation method thereof and single-component coating

A technology of blocked isocyanate and blocked isocyanate, applied in the field of coatings, can solve the problems affecting the water resistance and chemical resistance of the paint film, the limited cross-linking density of the paint film, and the insufficient cross-linking density of the paint film. Improved water and chemical resistance, easy-to-achieve results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] Another embodiment of the present invention is to provide a method for preparing the above-mentioned blocked isocyanate curing agent, which includes the following steps S1-S3.

[0054] S1. Mixing the chain extender and the polyisocyanate trimer to extend the chain to obtain a prepolymer.

[0055] Wherein, the polyisocyanate trimer is selected from at least one of isophorone diisocyanate trimer, hexamethylene diisocyanate trimer and toluene diisocyanate trimer, and the chain extender is selected from At least one of polyfunctional compounds containing hydroxyl and / or amino groups and water, the polyfunctional compound having an alkyl group with 2 to 12 carbon atoms.

[0056] In one embodiment, water or a diol chain extender with 2-12 carbon atoms is used, and the temperature for chain extension is 40°C-90°C.

[0057] In one embodiment, diamine or alcoholamine having 2-12 carbon atoms is used as the chain extender, and the temperature for chain extension is 5°C-10°C.

...

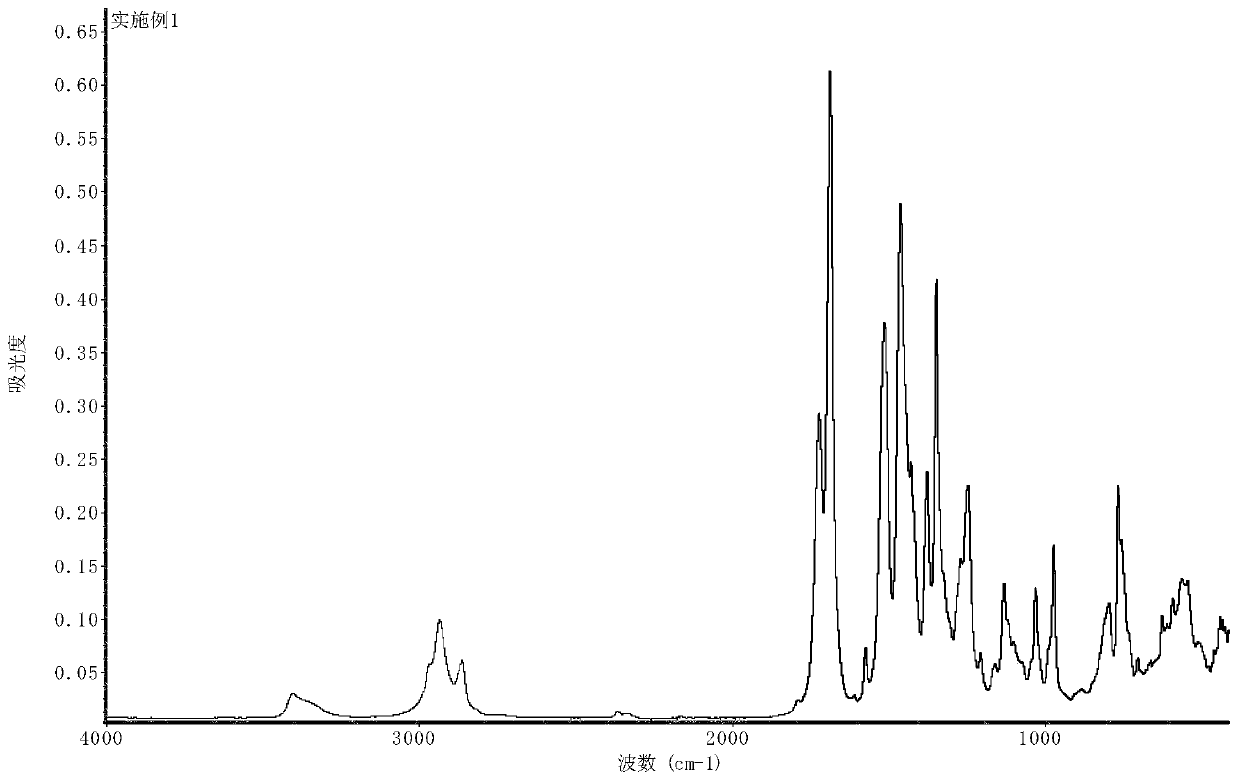

Embodiment 1

[0091] (1) Install a reflux condenser, a thermocouple, a thermometer, and a nitrogen tube on a four-necked round-bottomed flask, and add 50% cosolvent (a mixed cosolvent composed of trimethylbenzene and PMA), IPDI trimer , blowing in nitrogen at the same time, stirring and dispersing for 15min, then raising the temperature to 80°C, stopping blowing in nitrogen, adding H 2 O and 30% co-solvent were reacted for 2 hours to obtain a urea-based prepolymer.

[0092] (2) After the reaction is completed, cool down to 30°C, add 3,5-dimethylpyrazole, 20% co-solvent for capping reaction, the reaction temperature is 60°C, and the capping time is 1h, until NCO≤0.1% is measured , end capping, stop the reaction.

[0093] (3) Detect and adjust the solid content of the mixture obtained in step (2) to 85%, add diatomaceous earth to filter and discharge, and obtain a blocked isocyanate curing agent with a crosslinked structure.

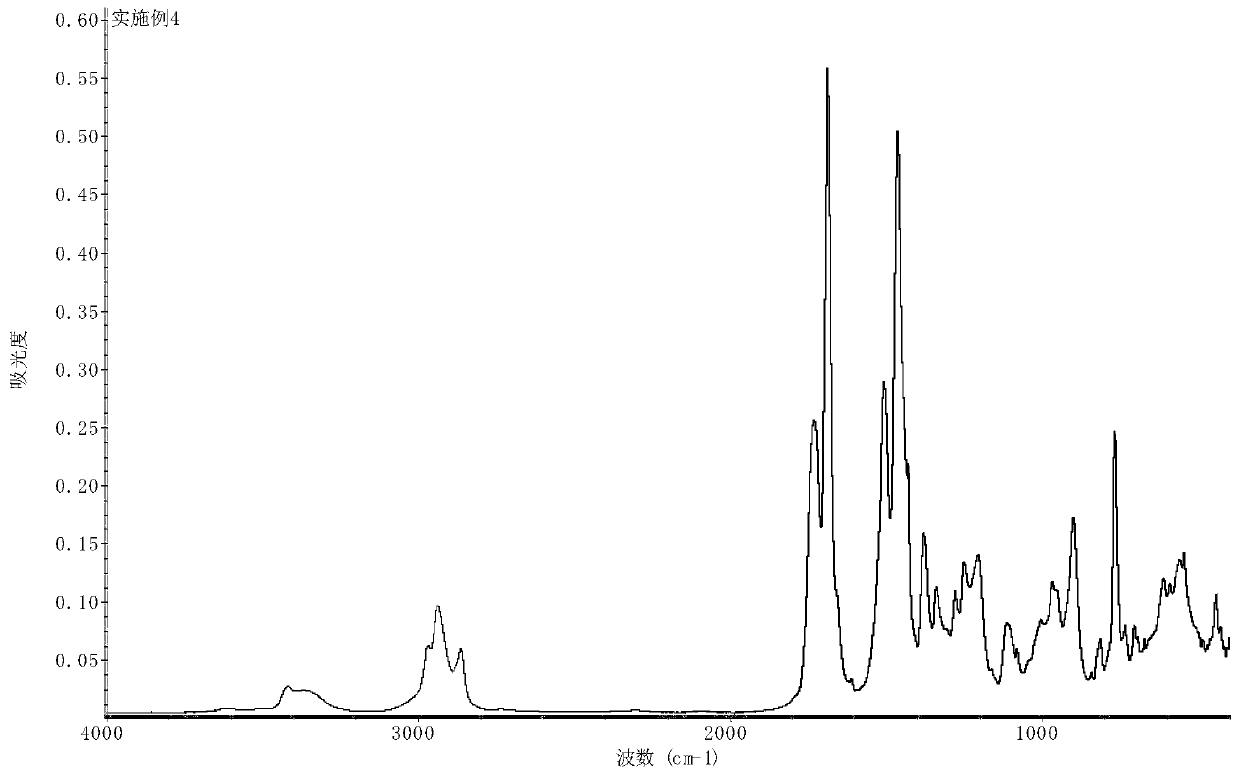

Embodiment 2

[0095] (1) Install a reflux condenser, a thermocouple, a thermometer, and a nitrogen tube on the four-necked round-bottomed flask, add 50% cosolvent and HDI trimer under stirring, blow into nitrogen simultaneously, stir and disperse for 15min, and then Raise the temperature to 80° C., stop blowing nitrogen, add ethylene glycol and 30% co-solvent, and react for 2 hours to obtain a urethane prepolymer.

[0096] (2) After the reaction is completed, cool down to 30°C, add 1,2,4-triazole and 20% co-solvent (trimethylbenzene / PMA) for capping reaction, the reaction temperature is 80°C, and the capping time is 0.5h, until When NCO≤0.1% is measured, the capping is completed and the reaction is stopped.

[0097] (3) Detect the solid content, adjust the solid content to 75%, add diatomaceous earth to filter the material, and obtain a blocked isocyanate curing agent with a cross-linked structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com