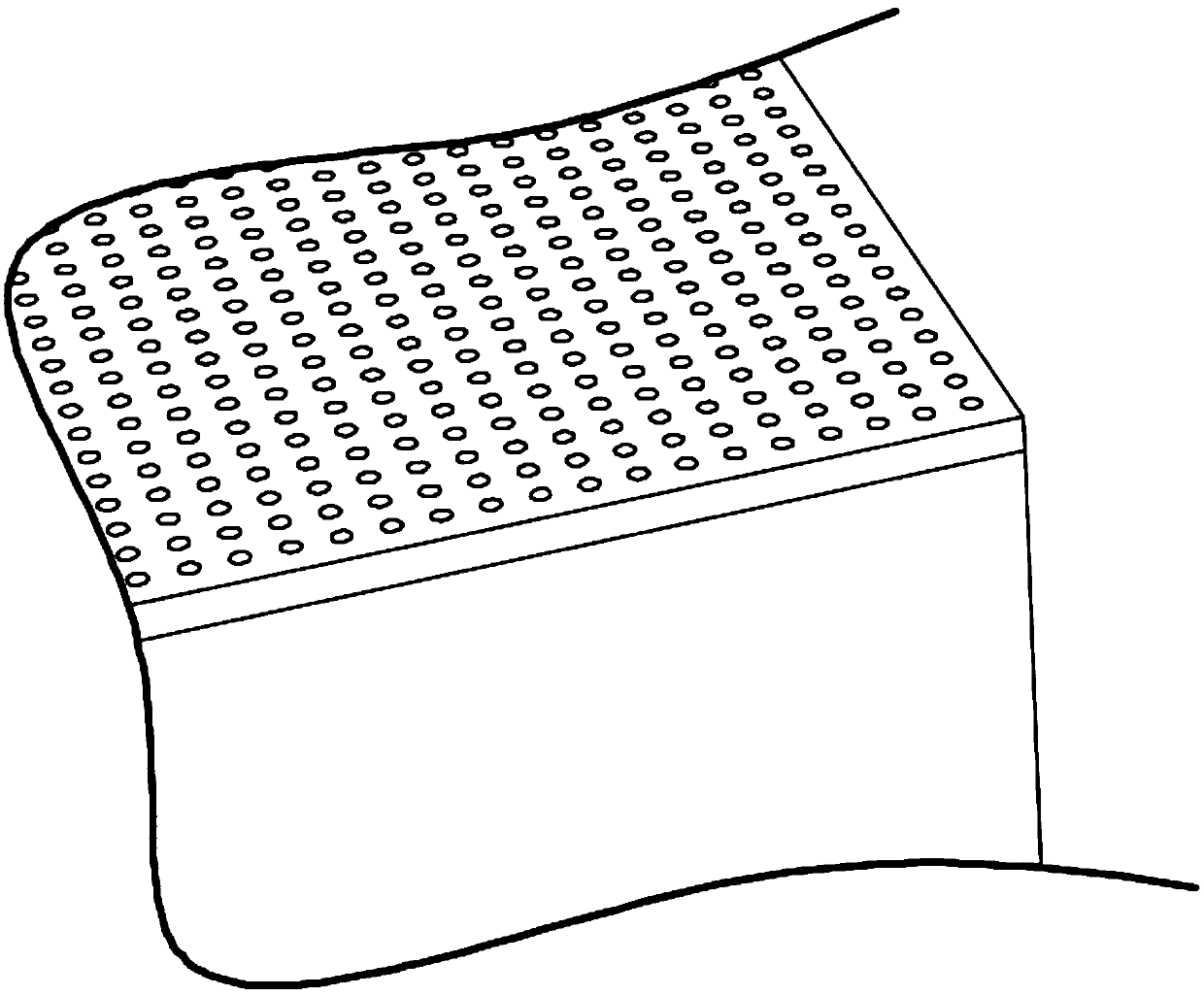

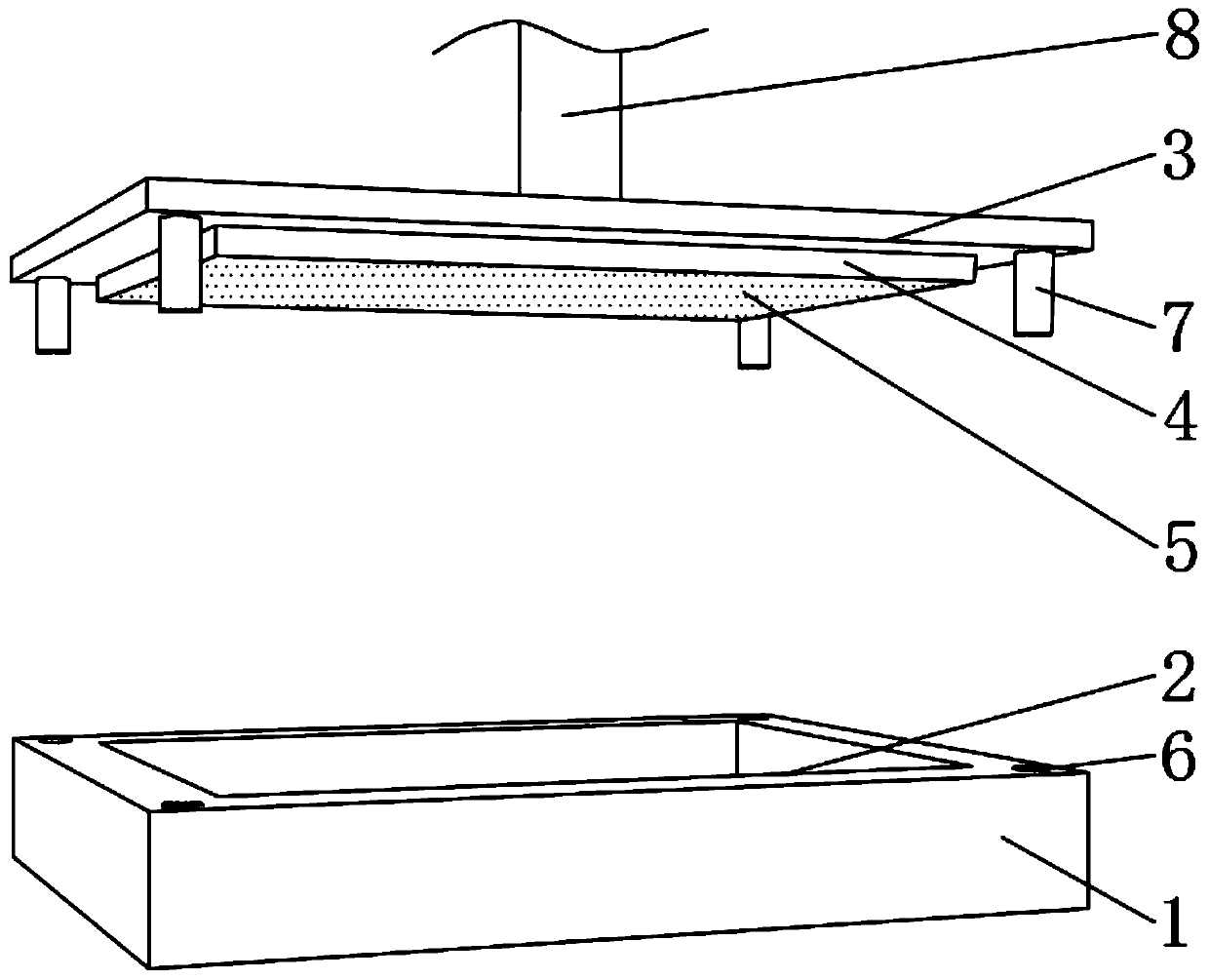

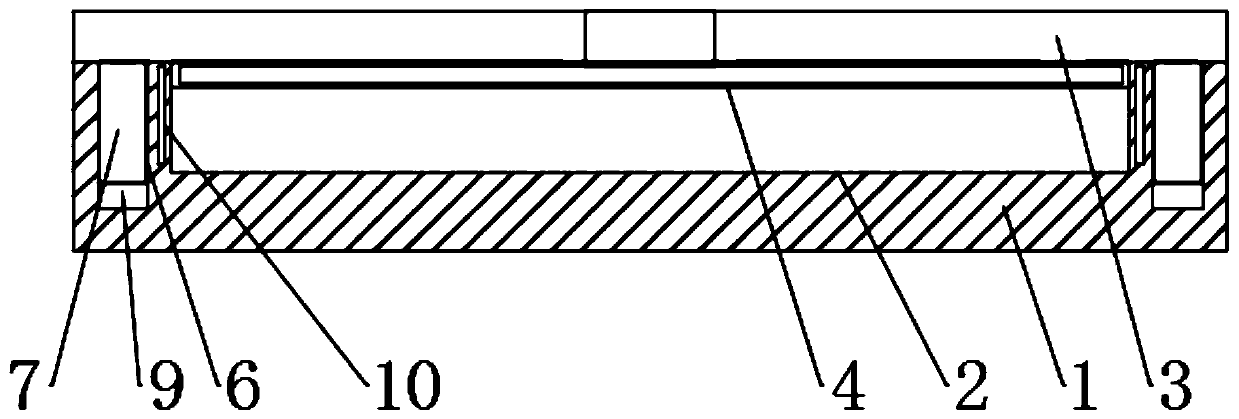

Quick-frozen honeycomb coating for plate and smearing method thereof

A quick-freezing honeycomb and board technology, applied in coatings, polyurea/polyurethane coatings, devices for coating liquid on the surface, etc., can solve the problems of low utilization rate of refrigerator quick-freezing, low quick-freezing efficiency, high difficulty, etc., and achieve the improvement of quick-freezing Efficiency, improved uniformity, improved thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A quick-frozen honeycomb coating for plates, including base material, filler, gain material, organic solvent and additives, the parts by weight of each component of the base material are as follows: 15 parts of fluorocarbon resin, 10 parts of acrylic resin, 5 parts of chlorosulfonated Polyethylene resin, 3 parts of silicon alkyd resin and 5 parts of polyurethane, the parts by weight of each component of the filler are as follows: 20 parts of nano-graphene, 12 parts of carbon fiber and 6 parts of cubic boron nitride, the parts by weight of each component of the gain material are as follows : 15 parts nano silicon dioxide, 15 parts nano titanium dioxide and 3 parts surfactant.

[0040] Chlorosulfonated polyethylene resin has good chemical corrosion resistance, physical and mechanical properties, aging resistance, heat resistance and low temperature resistance.

[0041] The organic solvent is divided into two parts with the same components, the weight ratio of one part to ...

Embodiment 2

[0058] A quick-frozen honeycomb coating for plates, including base material, filler, gain material, organic solvent and additives, the parts by weight of each component of the base material are as follows: 25 parts of fluorocarbon resin, 15 parts of acrylic resin, 7 parts of chlorosulfonated polystyrene Vinyl resin, 4 parts of silicon alkyd resin and 6 parts of polyurethane, the parts by weight of each component of the filler are as follows: 25 parts of nano-graphene, 15 parts of carbon fiber and 8 parts of cubic boron nitride, the parts by weight of each component of the gain material are as follows: 20 parts of nano silicon dioxide, 20 parts of nano titanium dioxide and 4 parts of surfactant.

[0059] Chlorosulfonated polyethylene resin has good chemical corrosion resistance, physical and mechanical properties, aging resistance, heat resistance and low temperature resistance.

[0060] The organic solvent is divided into two parts with the same components, the weight ratio of...

Embodiment 3

[0073]A quick-frozen honeycomb coating for plates, including base material, filler, gain material, organic solvent and additives, the parts by weight of each component of the base material are as follows: 35 parts of fluorocarbon resin, 20 parts of acrylic resin, 10 parts of chlorosulfonated Polyethylene resin, 5 parts of silicon alkyd resin and 8 parts of polyurethane, the parts by weight of each component of the filler are as follows: 30 parts of nano-graphene, 18 parts of carbon fiber and 10 parts of cubic boron nitride, the parts by weight of each component of the gain material are as follows : 30 parts nano silicon dioxide, 30 parts nano titanium dioxide and 6 parts surfactant.

[0074] Chlorosulfonated polyethylene resin has good chemical corrosion resistance, physical and mechanical properties, aging resistance, heat resistance and low temperature resistance.

[0075] The organic solvent is divided into two parts with the same components, the weight ratio of one part to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com