Periscope Detection Mechanism, Prediction System and Method for Cyclone Milling Tool

A detection mechanism and whirlwind milling technology, applied in general control systems, neural learning methods, control/regulation systems, etc., can solve the problems of low efficiency, increased labor, and increased errors in mechanical contact detection, and achieve high precision. The effect of online inspection, improving surface quality and liberating labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

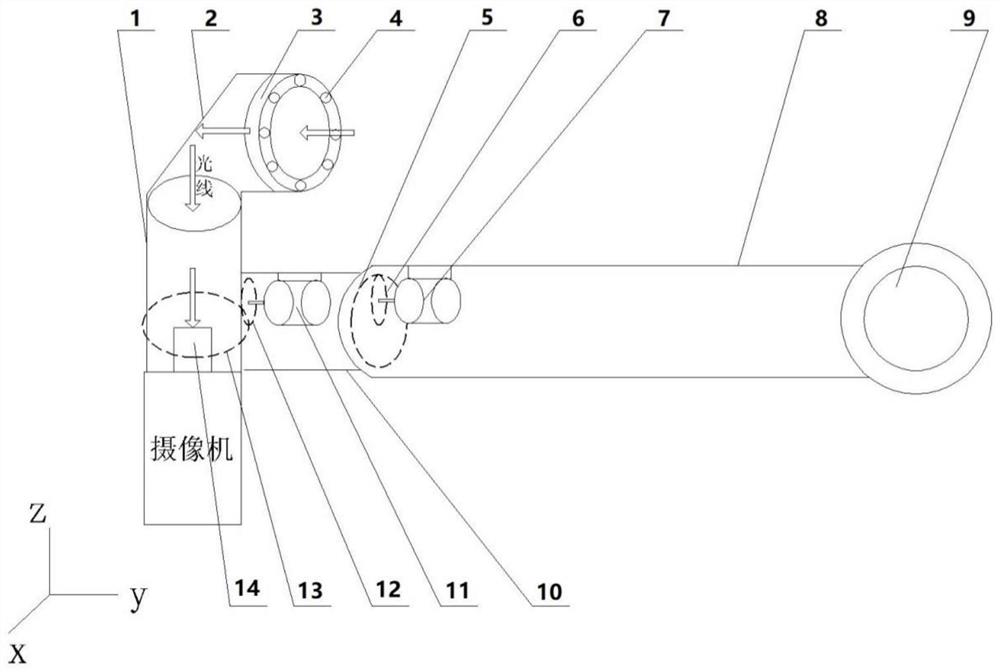

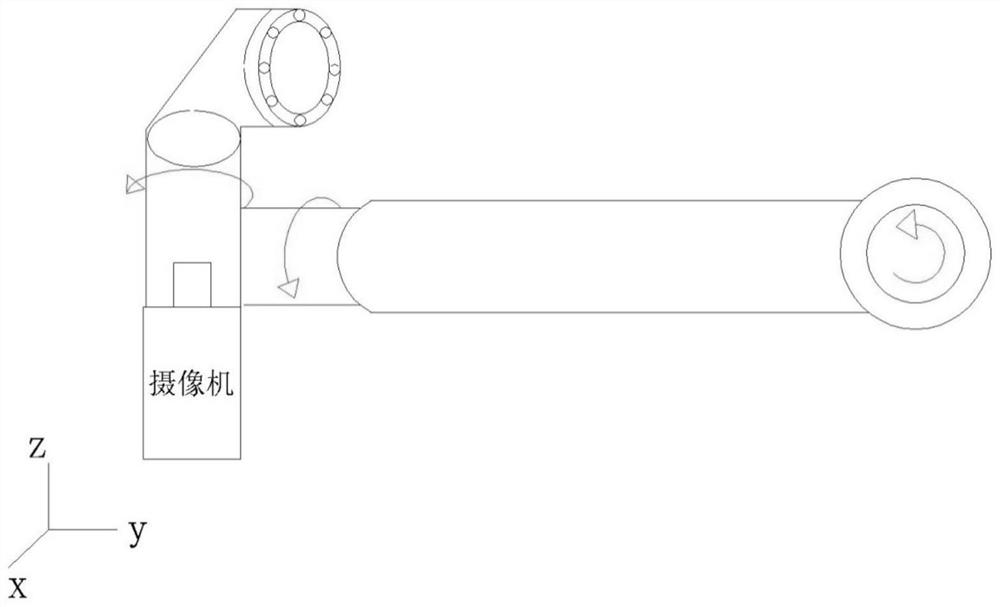

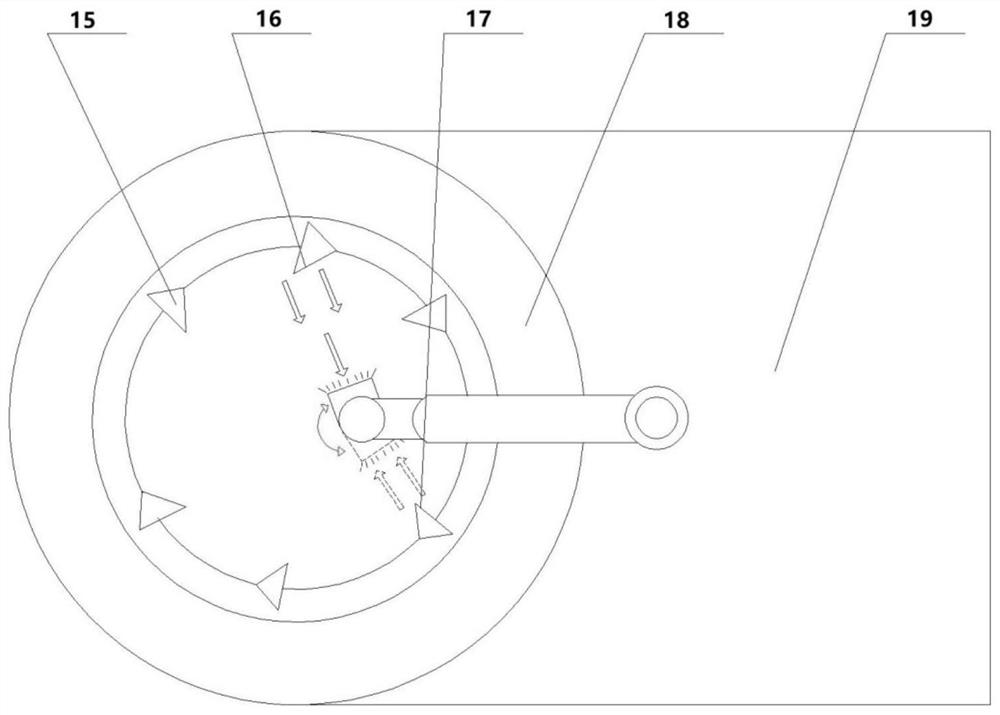

[0045] In a typical embodiment of the present invention, such as Figure 1-Figure 3 As shown, a periscope detection mechanism for whirlwind milling tools includes a mechanical arm, which is rotatably mounted on the whirlwind milling head housing 19, and a hollow lens barrel 1 is arranged at the end of the mechanical arm, and one side of the lens barrel 1 is bent. In order to make the lens barrel 1 be periscope type, one end of the lens barrel 1 is provided with an objective lens 3, and a plurality of supplementary light lamps 4 are arranged on the peripheral side of the objective lens 3, and a plurality of supplementary light lamps 4 are evenly arranged at the end of the lens barrel 1, and inside the other end A video camera is installed (or the lens 14 of the camera is arranged at the end of the lens barrel, the body of the camera is connected with the lens 14, and the body of the camera is arranged outside the lens barrel 1 to avoid damage to the lens 14), and a mirror is arr...

Embodiment 2

[0061] In order to overcome the deficiencies in the prior art, the present invention also provides a periscope prediction system for whirl milling cutter, comprising:

[0062] A kind of cyclone milling cutter described in embodiment 1 uses periscope detection mechanism;

[0063] The controller, the controller and a whirlwind milling tool use periscope detection mechanism data transmission to obtain the initial wear value of the milling tool, and the controller is connected with the whirlwind milling tool processing machine tool to obtain the spindle speed value, the tool feed speed value and Cutting depth value of the tool; in the milling process, for the same material, the wear rate of the tool mainly depends on the amount of milling, including the spindle speed, feed speed, depth of cut, etc. Therefore, through the input of these data, it can be Improve the accuracy of tool wear predictions.

[0064] In this prediction system, the machine vision mechanism mainly collects th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com