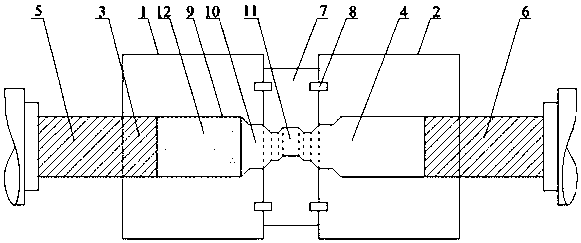

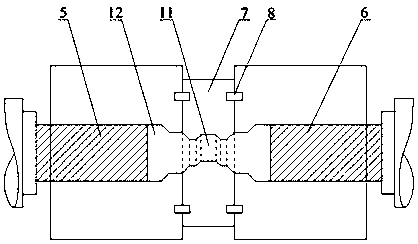

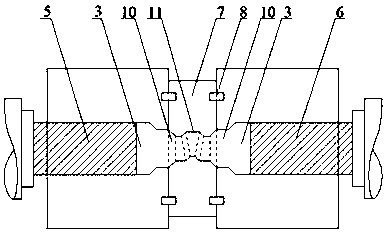

Rotary reciprocating extrusion device for superfine crystal magnesium alloy and processing method

A reciprocating extrusion and magnesium alloy technology, applied in metal extrusion, metal processing equipment, metal extrusion dies, etc., can solve the problems of unfavorable batch production, etc., and achieve the effect of simple structure, fine grain and uniform structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] All parts of the reciprocating extrusion die in the present invention are made of chromium tungsten-manganese steel, and the left and right extrusion die cavities and the internal die cavities of the rotating wheel have smooth surfaces with a roughness of Ra0.16-0.32 μm.

[0038] Materials and chemical reagents used: magnesium alloy profile: AZ31 magnesium alloy block blank; sandpaper: SiC, 600 mesh, 2 sheets; 1000 mesh, 2 sheets; 1200 mesh, 2 sheets; 2500 mesh, 2 sheets; high temperature graphite oil solution: C, 30ml; absolute ethanol: CH 3 CH 2 OH, 1200ml; Acetone: C 3 h 6 O, 800ml.

[0039] A variable channel rotary reciprocating extrusion processing technology and method for magnesium alloys, using the following steps:

[0040] (1) Install the rotary reciprocating extrusion device on the horizontal hydraulic extrusion machine, the installation is firm, the position and connection relationship of each part must be correct, and the operation should be done in seq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com