Compound amino acid injection and preparation method thereof

A compound amino acid and injection technology, which is applied in the direction of medical formula, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc., can solve the safety hazards of compound amino acid injections and reduce the degradation of tryptophan, etc. Achieve stable properties, reduce degradation, and simplify the prescription process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

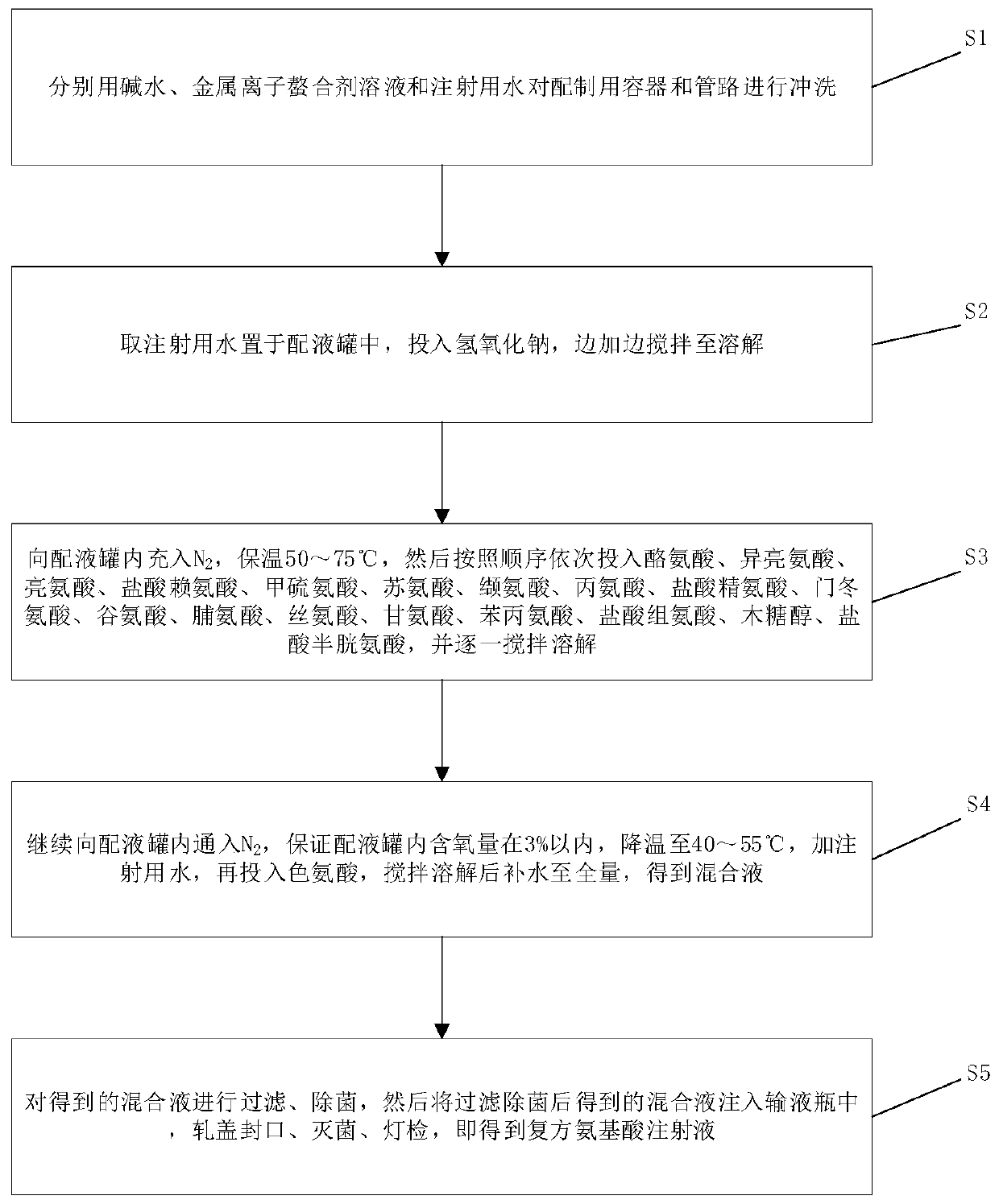

[0017] Please refer to figure 1 , the embodiment of the present invention provides a kind of preparation method of compound amino acid injection, comprises the following steps:

[0018] Step S1, pre-production treatment: wash the preparation container and pipeline with alkaline water, metal ion chelating agent solution and water for injection respectively;

[0019] Step S2, take 40% of the water for injection and put it in the liquid mixing tank, put in the prescribed amount of sodium hydroxide, stir while adding, and stir until dissolved;

[0020] Step S3, filling the liquid distribution tank with N 2 , keep warm at 50-75°C, and then put in the prescribed amount of tyrosine, isoleucine, leucine, lysine hydrochloride, methionine, threonine, valine, alanine, Arginine hydrochloride, aspartic acid, glutamic acid, proline, serine, glycine, phenylalanine, histidine hydrochloride, xylitol, cysteine hydrochloride, and stir to dissolve one by one;

[0021] Step S4, continue to fe...

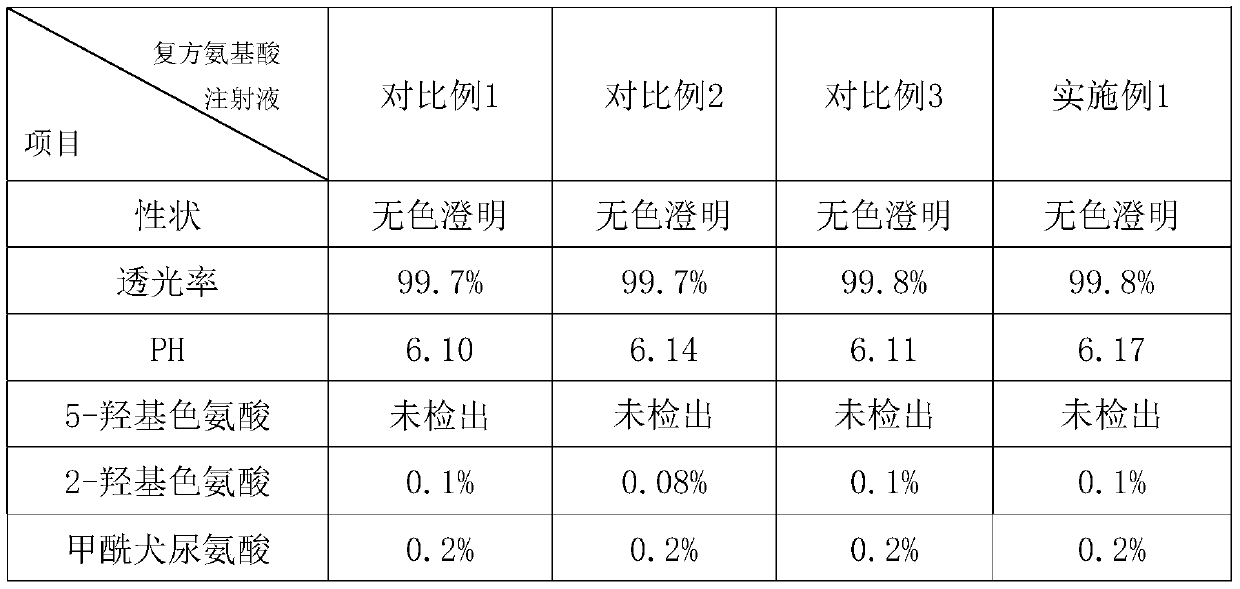

Embodiment 1

[0026] Rinse the preparation container and pipeline with alkaline water, metal ion chelating agent solution and water for injection respectively; take 350ml of water for injection and place it in the liquid mixing tank, put in 1.1g of sodium hydroxide, and stir until dissolved while adding; Fill the liquid tank with N 2 , keep warm at 65°C, then add 1.03g tyrosine, 1.74g isoleucine, 3.75g leucine, 3.33g lysine hydrochloride, 1.06g methionine, 1.95g threonine, 1.35g g valine, 1.82g alanine, 2.76g arginine hydrochloride, 1.26g aspartic acid, 1.87g glutamic acid, 0.98g proline, 0.75g serine, 3.22g glycine, 2.76g phenylalanine acid, 2.43g histidine hydrochloride, 52g xylitol, 0.46g cysteine hydrochloride, and stir and dissolve one by one; 2 , ensure that the oxygen content in the liquid mixing tank is within 3%, cool down to 45°C, add 420ml of water for injection, and then add 0.41g of tryptophan, stir and dissolve, replenish water to 1000ml, and obtain a mixed solution; use 0....

Embodiment 2

[0038] Rinse the preparation container and pipeline with alkaline water, metal ion chelating agent solution and water for injection respectively; take 400ml water for injection and place it in the liquid mixing tank, drop in 1.3g sodium hydroxide, and stir until dissolved while adding; Fill the liquid tank with N 2 , kept at 70°C, and then put in 1.13g tyrosine, 1.64g isoleucine, 3.68g leucine, 3.27g lysine hydrochloride, 1.03g methionine, 1.90g threonine, 1.25g g valine, 1.85g alanine, 2.72g arginine hydrochloride, 1.12g aspartic acid, 1.81g glutamic acid, 0.87g proline, 0.67g serine, 3.18g glycine, 2.83g phenylalanine acid, 2.41g histidine hydrochloride, 48g xylitol, 0.41g cysteine hydrochloride, and stir and dissolve one by one;2 , ensure that the oxygen content in the liquid mixing tank is within 3%, lower the temperature to 50°C, add 300ml of water for injection, and then add 0.35g of tryptophan, stir and dissolve, replenish water to 1000ml, and obtain a mixed solution;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com