Amidoxime-modified silica nano-microsphere composite material and preparation method thereof

A technology of silicon dioxide and nano-microspheres, applied in the field of materials, can solve the problem of less adsorption sites, and achieve the effects of increasing the saturated adsorption capacity, selecting good adsorption performance, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

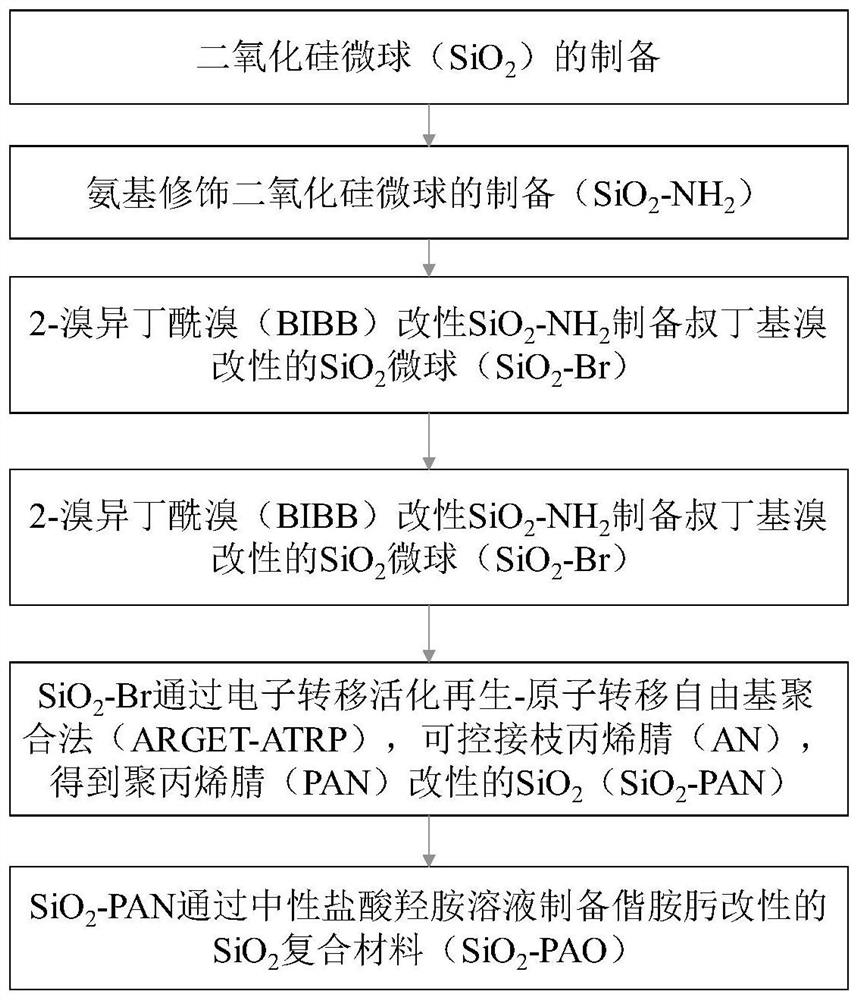

[0061] Preferably, the preparation method of amidoxime modified silica nano-microsphere composite material of the present invention comprises:

[0062] (1) SiO 2 -NH 2 preparation of

[0063] Take SiO with a particle size of 280-320nm in anhydrous state 2 Microspheres, preferably 300nm SiO 2 Mix microspheres, toluene and APTES, stir and react at 95-100°C for 18-20 hours to obtain SiO 2 -NH 2 ; the SiO 2 The mass ratio of microspheres, toluene and APTES is: 1.0~1.2:17.32~19.05:1.89~2.08;

[0064] (2) BIBB modified SiO 2 -NH 2 Preparation of SiO 2 -Br

[0065] Take SiO 2 -NH 2 , toluene and triethylamine, stirred at 0°C (in an ice-water mixture water bath) and added a uniform mixed solution of BIBB and toluene, reacted for 3 to 6 hours, raised the temperature to room temperature and reacted for 12 to 14 hours to obtain SiO 2 -Br;

[0066] Step (2) described SiO 2 -NH 2 1. The mass ratio of toluene and triethylamine is: 1.0~1.2:12.99~17.32:1.46~1.60; the mass rati...

Embodiment 1

[0097] A kind of amidoxime polymer brush modified SiO 2 The specific steps of the preparation method of the nano-microsphere composite material are as follows:

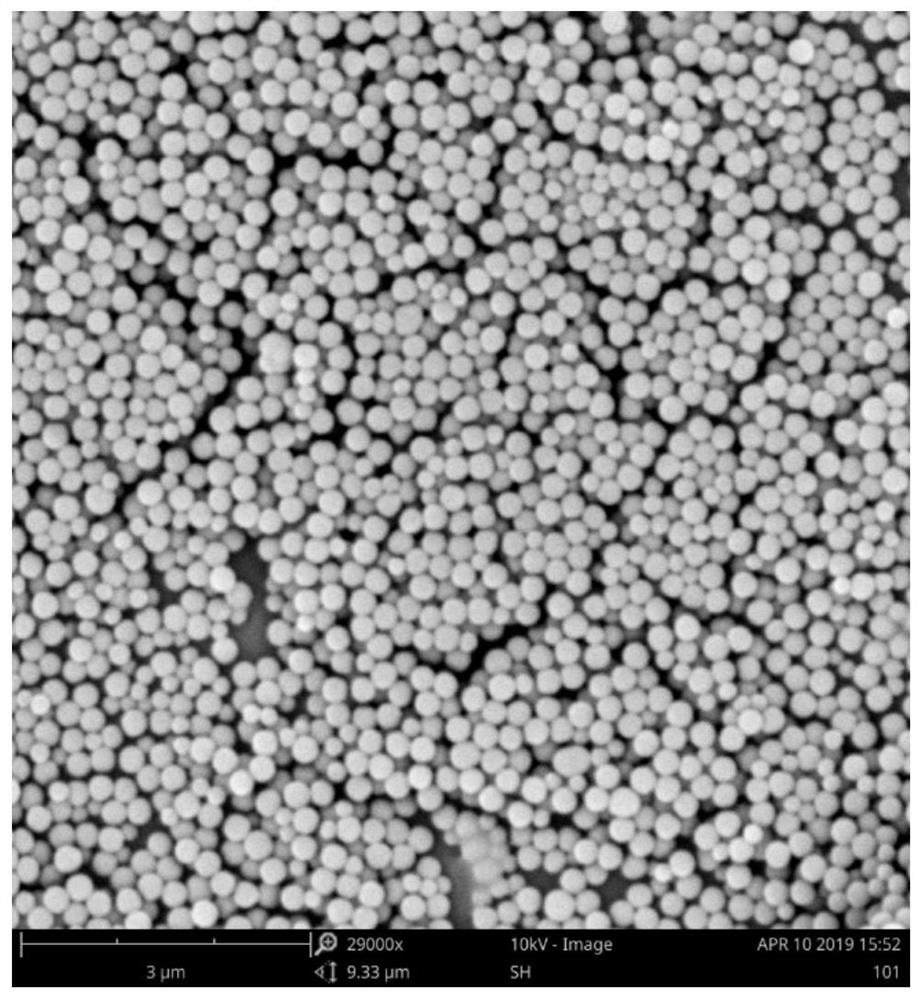

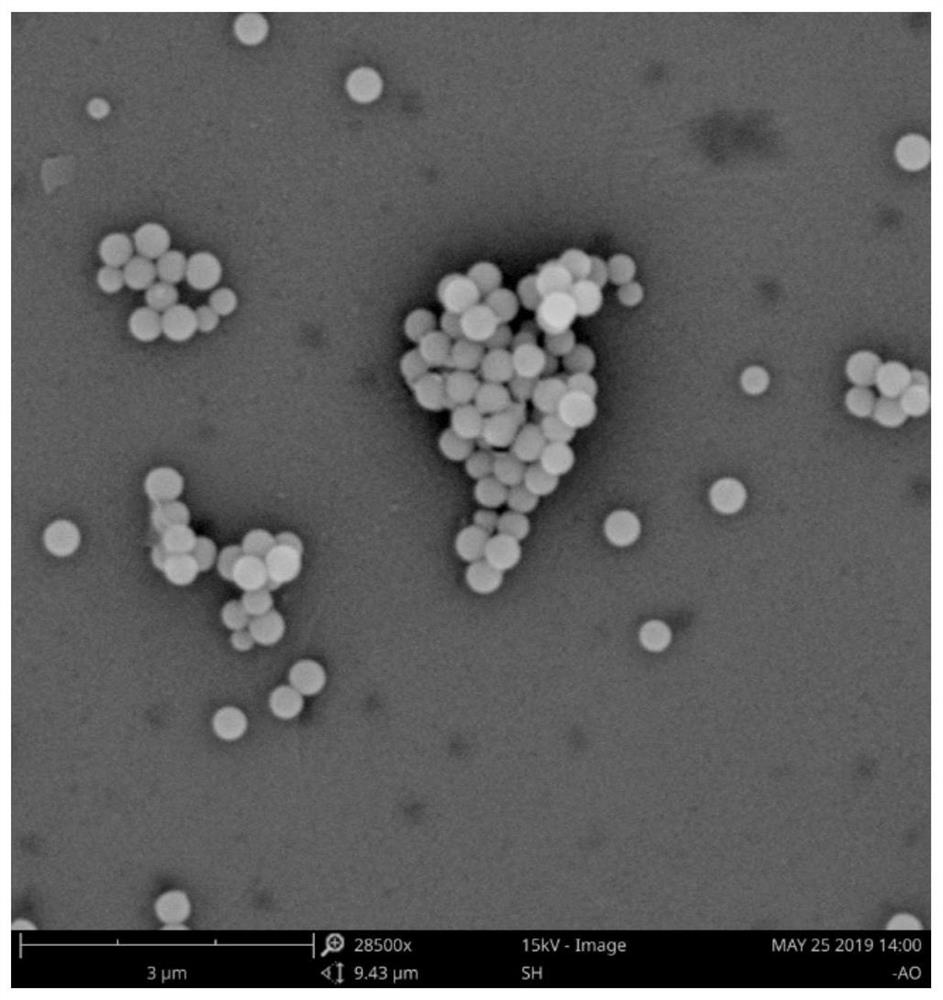

[0098] (1) SiO 2 Preparation of nanospheres: Take 100mL of absolute ethanol, 6.0mL of distilled water, and 8.0mL of ammonia water in a beaker in sequence, stir evenly, place in a 40°C oil bath, and stir magnetically for 2 hours to fully stir the system, then take Slowly add 6.0mL tetraethyl orthosilicate into the three-neck flask drop by drop at a rate of 0.1mL / min, and then continue to stir for 12 hours to obtain a milky white colloidal solution; take out the prepared colloidal solution of silica microspheres and centrifuge at 8000rmp , Pour out the supernatant, add deionized water and absolute ethanol to wash twice by centrifugation, put the final product in a vacuum drying oven at 60°C for 24 hours, and then prepare silica microspheres SiO 2.

[0099] (2) SiO 2 -NH 2 preparation, the specific operations are as...

Embodiment 2

[0116] A kind of amidoxime polymer brush modified SiO 2 The specific steps of the preparation method of the nano-microsphere composite material are as follows:

[0117] (1) SiO 2 Preparation of nanospheres: Take 110mL of absolute ethanol, 6.5mL of distilled water, and 8.2mL of ammonia water in a beaker in sequence, stir evenly, place in an oil bath at 45°C, and stir magnetically for 3 hours to fully stir and mix the system, then take Add 8.0mL tetraethyl orthosilicate slowly into the three-neck flask drop by drop at a rate of 0.2mL / min, and then continue to stir for 12 hours to obtain a milky white colloidal solution; take out the prepared colloidal solution of silica microspheres and centrifuge at 8000rmp , Pour out the supernatant, add deionized water and absolute ethanol to wash twice by centrifugation, put the final product in a vacuum drying oven at 65°C for 36h, and then prepare silica microspheres SiO 2 .

[0118] (2) SiO 2 -NH 2 preparation, the specific operation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com