Ammonia-modified carbon quantum dot and preparation method thereof, and application of ammonia-modified carbon quantum dot in lithium-sulfur battery electrolyte

A technology of carbon quantum dots and lithium-sulfur batteries, applied in the application of ammonia-modified polymer carbon quantum dots as an electrolyte additive for lithium-sulfur batteries, ammonia-modified polymer carbon quantum dots and their preparation, and the field of ammonia-modified carbon quantum dots , which can solve the problems of high application cost, insignificant effect, and large amount of addition, and achieve the effect of low cost of raw materials, improved cycle performance, and small amount of addition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Preparation of ammonia-modified polymer carbon quantum dots:

[0041] (1) Mix 40mL of acetaldehyde with sodium hydroxide to prepare a 1.5mol / L sodium hydroxide / acetaldehyde mixture, let it stand for 2 hours, add an appropriate amount of concentrated hydrochloric acid, adjust its pH to neutral, and set the temperature at 10000r / min Centrifuge for 10 min, wash with deionized water for 5 times, and vacuum dry at 80° C. for 24 h to obtain carbon quantum dots.

[0042] (2) Dissolve the 200 mg of carbon quantum dots in 30 ml of water, add 30 ml of ammonia water, reflux for 12 hours, and centrifugally dry to obtain ammonia-modified carbon quantum dots with a nitrogen content of 5%.

[0043] This example is basically the same as the comparative example, the only difference is that 0.01wt% ammonia-modified polymer carbon quantum dots are added to the electrolyte.

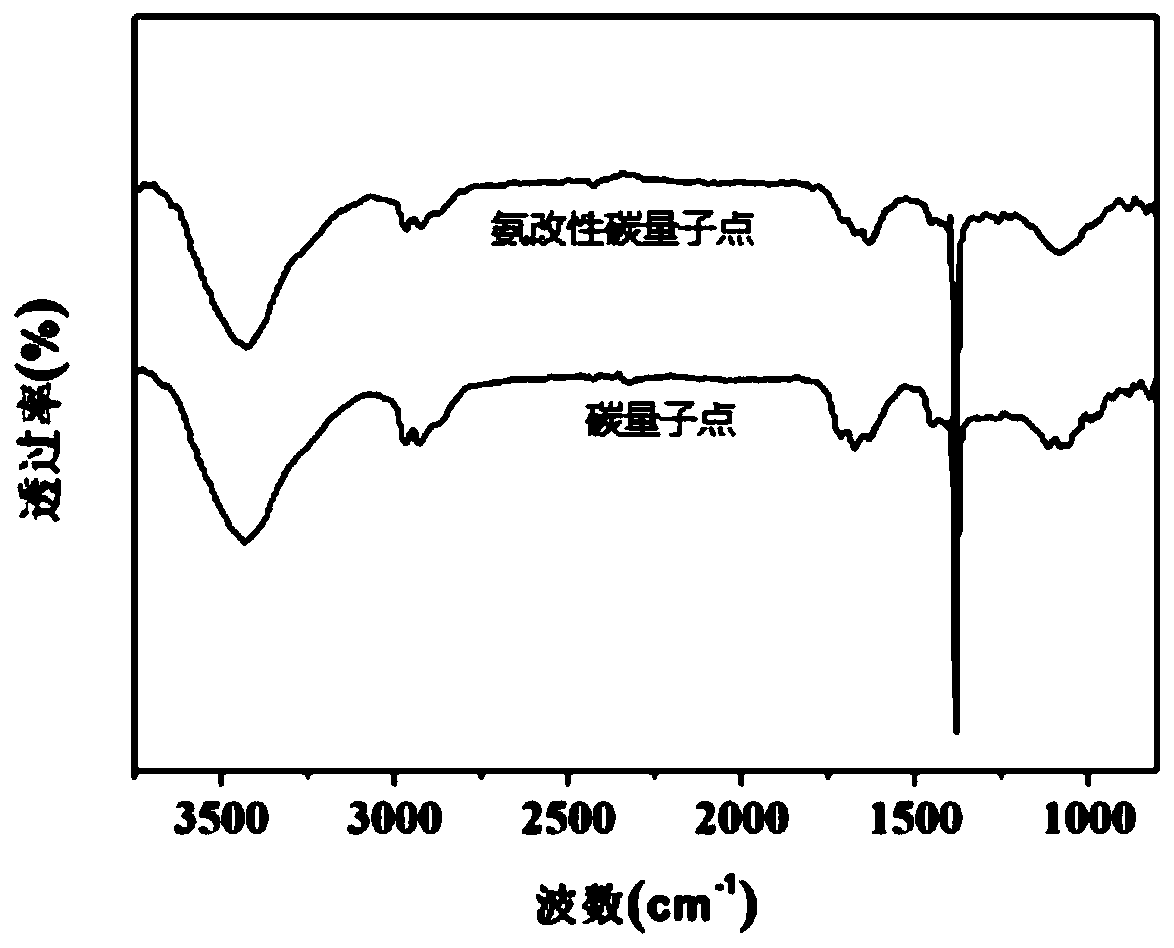

[0044] figure 1 It is the comparison of infrared images of polymer carbon quantum dots modified with ammonia and ...

Embodiment 2

[0047] This embodiment is basically the same as Embodiment 1, the only difference is that 0.05 wt% ammonia-modified polymer carbon quantum dots are added to the electrolyte.

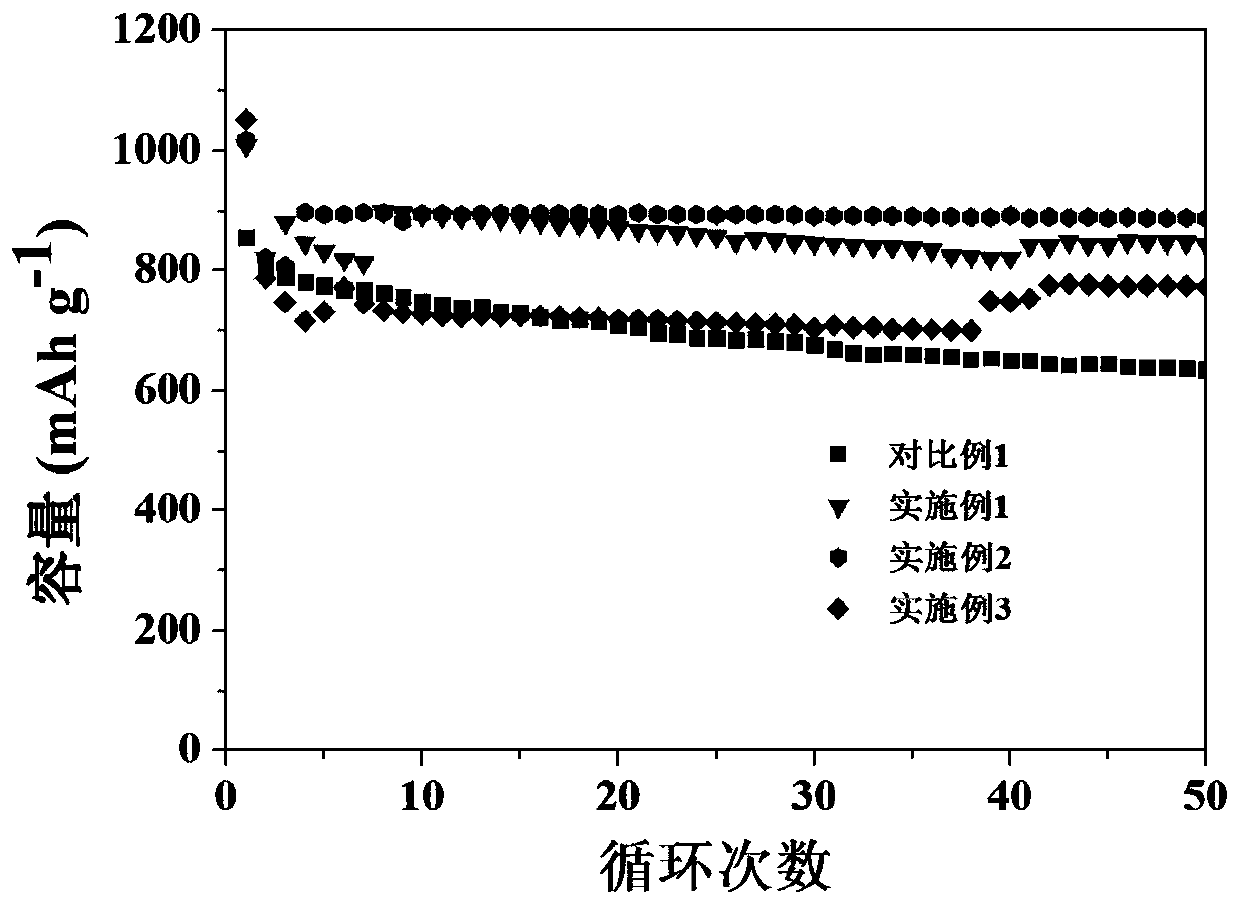

[0048] from image 3 It can be seen that at a current density of 837.5mAg -1 The capacity remains at 887.0mAh g for 50 laps of the next cycle -1 . Compared with Comparative Example 1, it exhibits high capacity and cycle stability.

Embodiment 3

[0050] This embodiment is basically the same as Embodiment 1, the only difference is that 0.1 wt% ammonia-modified polymer carbon quantum dots are added to the electrolyte.

[0051] from image 3 It can be seen that at a current density of 837.5mAg -1 The capacity remains at 773.7mAh g for 50 laps under the next cycle -1 . Compared with Comparative Example 1, it exhibits high capacity and cycle stability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com