Method for preparing crystalline wine bottle cap

A technology for wine bottle caps and crystals, applied in glass pressing, glass manufacturing equipment, manufacturing tools, etc., can solve problems such as difficulty in O2 discharge, increase in optical density of glass, decrease in optical density of glass, etc., and achieve collection and ornamental value Effects of lifting, less loss of dust and exhaust gas, and stable generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033]A crystal wine bottle cap, the material used in the wine bottle cap includes: 10g glass; 100g quartz sand; 70g soda ash; 20g potassium carbonate; 4g barium carbonate; 50g calcite; 10g borax; 4g sodium nitrate; Sodium; 2g clarifying agent; 4g alumina; 0.5g antimony oxide; 0.8g copper oxide; 0.04g cobalt oxide; 0.01g zirconia.

[0034] Described clarifying agent is a kind of organic-inorganic hybrid glass clarifying agent, and its preparation method is as follows:

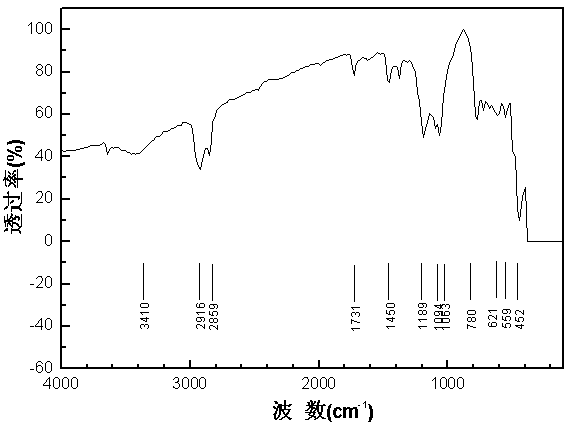

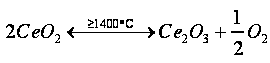

[0035] After mixing 5g of rubidium oxide and 1g of cerium oxide uniformly, calcining at high temperature for 5min, then mixing the calcined rare earth oxide with 10g of fumed silica, 15g of bentonite, 0.03g of perfluoroalkylsilyl mica, 3g of sodium fluorosilicate and 0.5g of nano-zinc oxide were stirred and mixed uniformly to obtain an inorganic solid material, and then 3g of N,N-dimethyldithioformamide propane sulfonate and 0.8g of hexadecyl trimethyl dihydrogen phosphate Ammonium, 0.3g of sodium triacetoxybo...

Embodiment 2

[0049] A kind of crystal wine bottle cap, the material that described wine bottle cap adopts comprises: 15g glass; 300g quartz sand; 80g soda ash; 25g potassium carbonate; 7g barium carbonate; 60g calcite; 13g borax; 6g sodium nitrate; Sodium; 5g clarifying agent; 6g alumina; 0.8g antimony oxide; 1g copper oxide; 0.06g cobalt oxide; 0.05g zirconia.

[0050] Described clarifying agent is a kind of organic-inorganic hybrid glass clarifying agent, and its preparation method is as follows:

[0051] After mixing 8g of rubidium oxide and 4g of cerium oxide uniformly, calcining at high temperature for 10min, then mixing the calcined rare earth oxide with 15g of fumed silica, 20g of bentonite, 0.01g of perfluoroalkylsilyl mica, 6g of sodium fluorosilicate and 2.5g of nano-zinc oxide were stirred and mixed uniformly to obtain an inorganic solid material, and then 5g of N,N-dimethyldithioformamide propane sulfonate and 2.6g of hexadecyl trimethyl dihydrogen phosphate Ammonium, 0.05g of...

Embodiment 3

[0063] A crystal wine bottle cap, the material used in the wine bottle cap includes: 15g glass; 200g quartz sand; 80g soda ash; 25g potassium carbonate; 6g barium carbonate; 60g calcite; 13g borax; 6g sodium nitrate; Sodium; 5g clarifying agent; 6g alumina; 0.9g antimony oxide; 1.2g copper oxide; 0.08g cobalt oxide; 0.09g zirconium oxide.

[0064] Described clarifying agent is a kind of organic-inorganic hybrid glass clarifying agent, and its preparation method is as follows:

[0065] After mixing 10g of rubidium oxide and 8g of cerium oxide uniformly, calcining at high temperature for 15min, then mixing the calcined rare earth oxide with 20g of fumed silica, 30g of bentonite, 0.05g of perfluoroalkylsilyl mica, 9g of sodium fluorosilicate and 5g of nano-zinc oxide were stirred and mixed uniformly to obtain an inorganic solid material, and then 8g of N,N-dimethyldithioformamide propane sulfonate and 3.6g of hexadecyl trimethyl ammonium dihydrogen phosphate , 0.9g of sodium tri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com