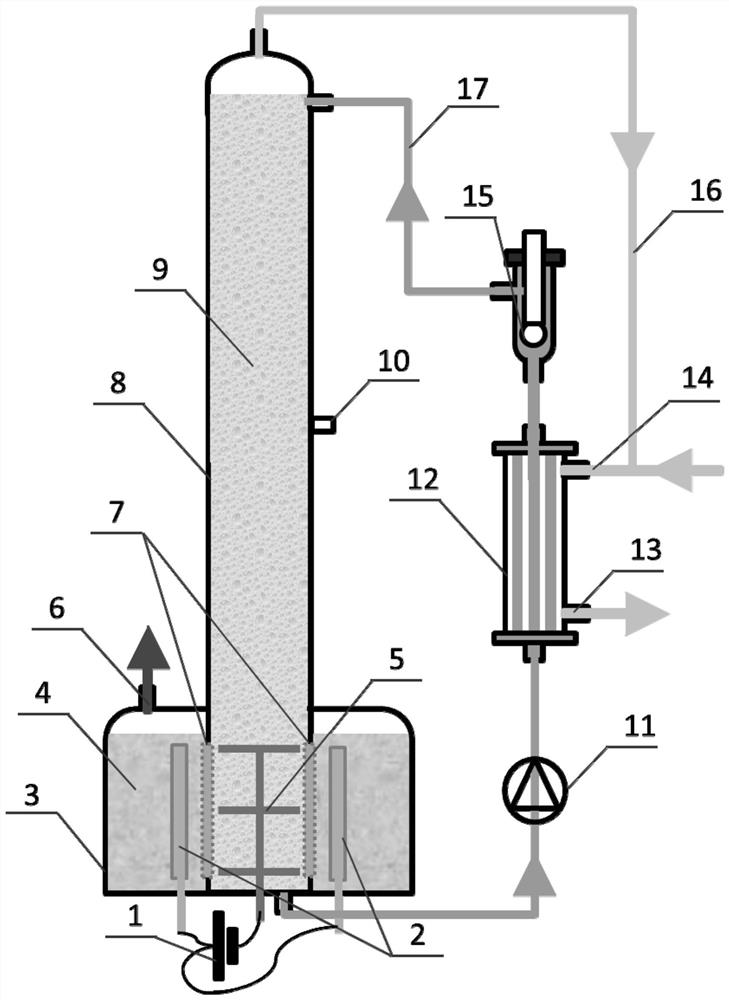

A kind of electrolytic hydrogen bubble tower microbial electrosynthesis reactor and using method thereof

A technology of microbial electrosynthesis and bubble tower, applied in the direction of bioreactor/fermenter combination, stress-stimulated microbial growth method, specific-purpose bioreactor/fermenter, etc., can solve the high current density and high current density of microbial electrosynthesis High coulombic efficiency cannot be achieved at the same time, so as to avoid the loss of bacteria, shorten the start-up time, and increase the biomass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

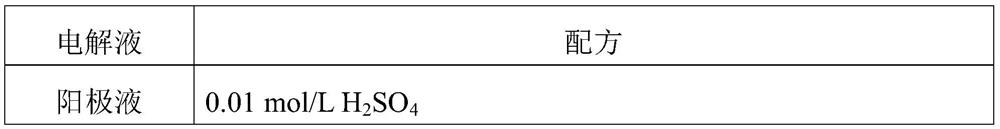

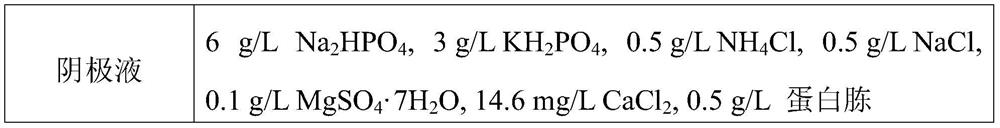

Method used

Image

Examples

Embodiment 1

[0035] The external current is 1000mA, CO 2 The gas inlet rate was 2mL / min, and the pH of the reactor was controlled at around 7. The cathode of the reactor was inoculated with the mixed flora of homoacetogenic bacteria enriched in the laboratory, and the cumulative concentration of acetic acid in the reactor reached 30g / L during the 30d operation period, the average acetogenic rate reached 0.9g / L / d, and the average coulomb The efficiency reaches 70%.

Embodiment 2

[0037] As in the reactor and operating conditions of implementation 1, when the reactor is inoculated with the enriched mixed flora of hydrogenophilic methanogens, the methane production rate of the reactor increases rapidly to 0.35L / L / d within 5 days, and then stabilizes Around this value, the coulombic efficiency of the reactor remains around 65% during the stationary phase.

Embodiment 3

[0039] Such as implementing the reactor and operating conditions of 2, when the operating current of the reactor and the CO 2 When the gas inlet rate increased to 2200mA and 4.4mL / min, the methane production rate of the reactor increased to 0.92L / L / d, and the Coulombic efficiency also increased to 78%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com