Cement-based adsorbent, and preparation method and application thereof

An adsorbent and cement-based technology, applied in the field of adsorbent preparation, can solve the problems of general adsorption effect, long adsorption time of heavy metal ions, restrictions on application and promotion, etc., and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

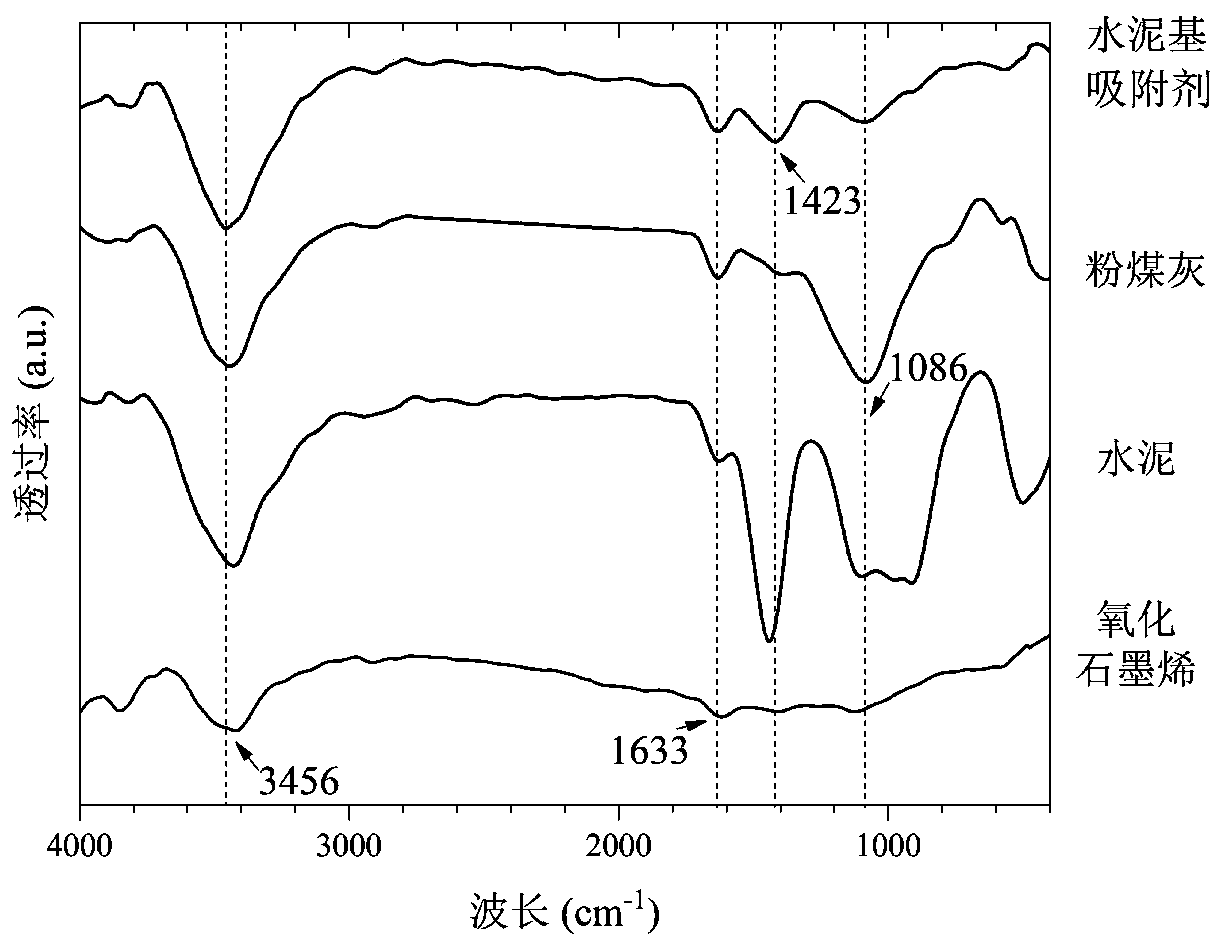

[0039] The present invention also provides a preparation method of the cement-based adsorbent described in the above technical solution, comprising the following steps:

[0040] Combine fly ash powder with Ca(OH) 2 The solutions are mixed to carry out modification reaction to obtain modified fly ash;

[0041] After mixing the modified fly ash, graphene oxide powder, polycarboxylate water reducer, cement, foaming agent and water, curing is carried out to obtain the cement-based adsorbent.

[0042] In the present invention, the fly ash powder is preferably ball-milled with Ca(OH) 2 The solution is mixed. In the present invention, the ball milling is preferably carried out in a ball mill, the speed of the ball milling is preferably 250-350r / min, more preferably 300r / min; the time of the ball milling is preferably 2h, and the particle size after the ball milling is Preferably it is 80 mesh. In the present invention, there is no special limitation on the specific operation of t...

Embodiment 1

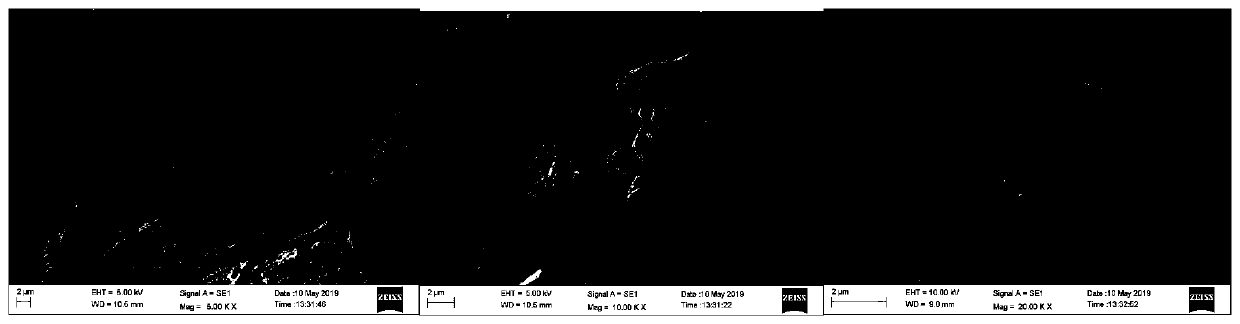

[0059] The fly ash was ball milled on a ball mill at a speed of 300r / min for 2h and passed through an 80-mesh sieve to obtain a fly ash powder; 7g of the fly ash powder was mixed with a mass concentration of 2moL / LCa(OH) 2 The solution is 1g: 6mL according to the dosage ratio, stirred in a 90°C water bath at a speed of 300r / min for 30min, then centrifuged, washed until neutral, dried, and ground through a 100-mesh sieve to obtain modified fly ash;

[0060] Weigh 0.5g graphene oxide, add it into 8mL distilled water, and ultrasonicate for 2 hours to obtain a uniformly dispersed graphene oxide suspension, mix it with 1mL PCAQ8081 polycarboxylate superplasticizer, and stir at 40°C and 200r / min 20min, obtain graphene oxide / polycarboxylate superplasticizer mixed solution;

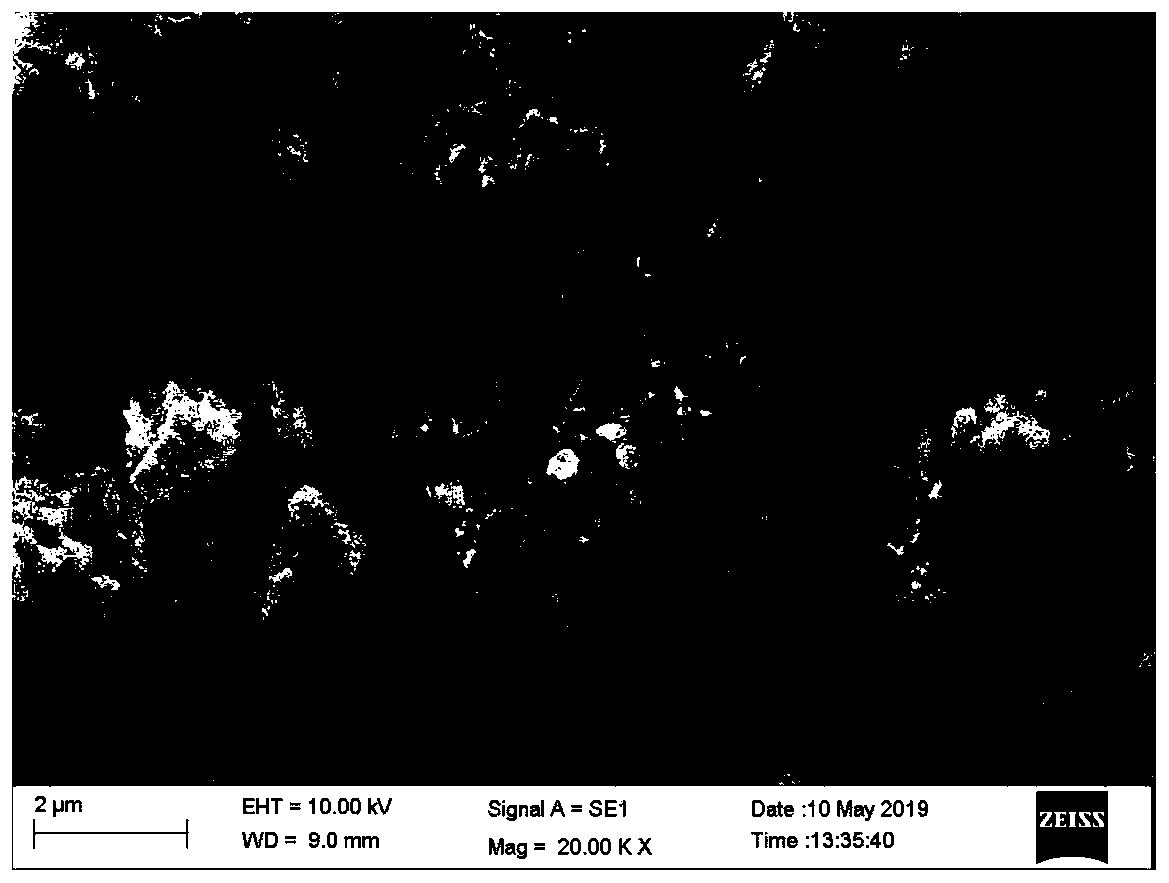

[0061] Weigh 10g of cement and the obtained modified fly ash in a stirrer, add 4.5mL graphene oxide / polycarboxylate superplasticizer mixed solution and 0.5mL sodium dodecylbenzene sulfonate foaming agent successi...

Embodiment 2

[0068] The fly ash was ball milled on a ball mill at a speed of 300r / min for 2h and passed through an 80-mesh sieve to obtain fly ash powder; 2 The solution is 1g: 5mL according to the dosage ratio, stirred in a 90°C water bath at a speed of 300r / min for 30min, then centrifuged, washed until neutral, dried, and ground through a 100-mesh sieve to obtain modified fly ash;

[0069]Weigh 1g of graphene oxide, add it into 10mL of distilled water, and ultrasonicate for 2 hours to obtain a uniformly dispersed graphene oxide suspension, mix it with 2mL of PCAQ8081 polycarboxylate superplasticizer, and stir for 20min at 30°C and 200r / min. Obtain graphene oxide / polycarboxylate superplasticizer mixed solution;

[0070] Weigh 10g of cement and the obtained modified fly ash in a stirrer, add 7mL graphene oxide / polycarboxylate superplasticizer mixed solution and 0.6mL sodium dodecylbenzene sulfonate foaming agent in turn, at 30r / At a stirring speed of 1 min, stir for 1 min, then add the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com