Brown impregnated bond paper and manufacturing process thereof

A preparation process and technology of brown paper, applied in the field of papermaking, can solve the problems affecting the use of construction template paper, high water absorption of construction template paper, poor antibacterial properties, etc., and achieve the effects of reducing water absorption, reducing water absorption, and improving wet strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

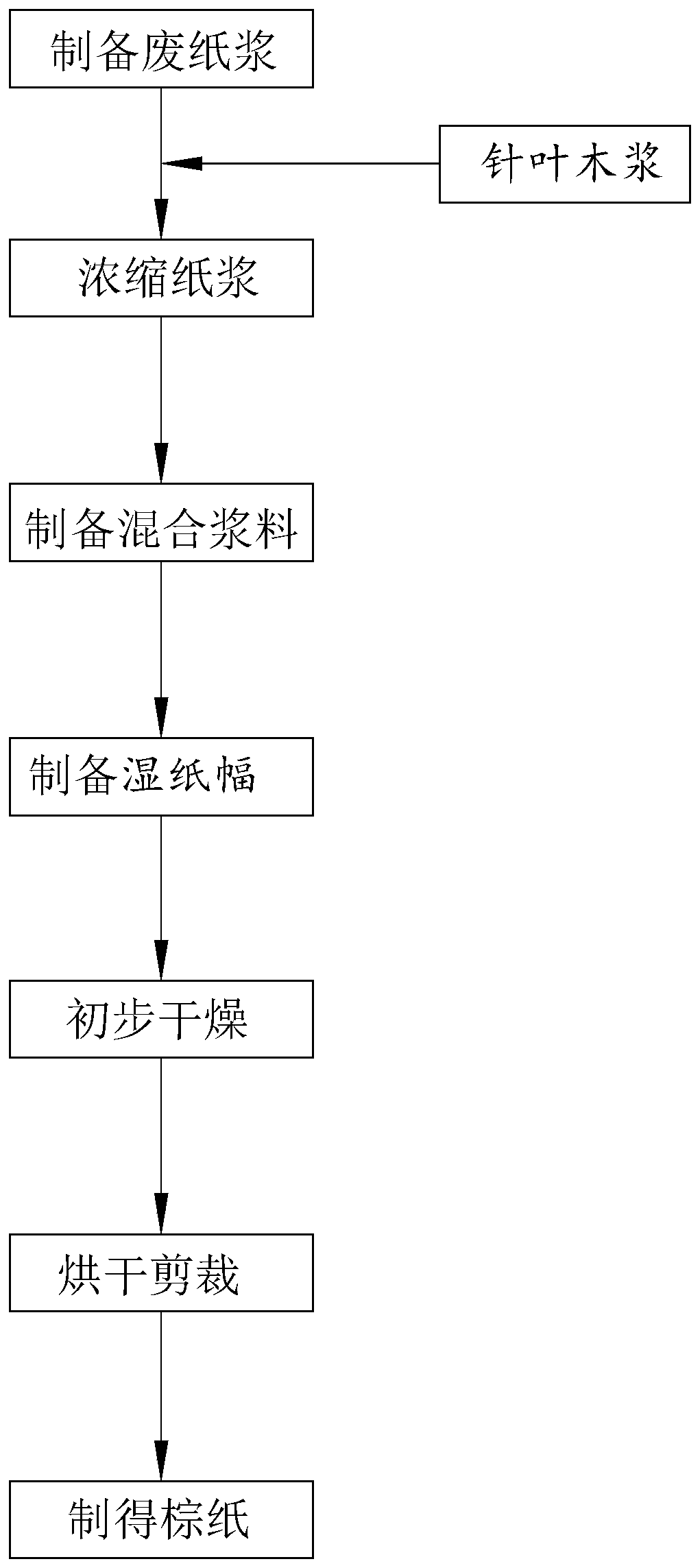

[0077] refer to figure 1 , is a kind of palm paper preparation process disclosed by the present invention, comprises following preparation process:

[0078] S1: Make waste paper pulp from waste printed paper: put the waste printed paper into a container, pour water at 75°C, soak for 25 minutes, and then crush the soaked printed paper into pulp fragments with a diameter of 50-100nm. Waste paper pulp with a mass concentration of 4% was obtained.

[0079] S2: a. Preparation of wet strength agent: mix 8% sodium dihydrogen phosphate, 6% disodium hydrogen phosphate and 36% water evenly to prepare a buffer;

[0080] Mix 25% amine epichlorohydrin resin, 25% ester core-shell emulsion and buffer uniformly to prepare wet strength agent;

[0081] b. Prepare antibacterial agent: mix 12% green tea extract, 12% Scherichia safflower extract, 12% mugwort extract, 12% chitosan, 3% coupling agent and 27% water After uniformity, add 22% calcined bentonite and mix uniformly to obtain the first ...

Embodiment 1

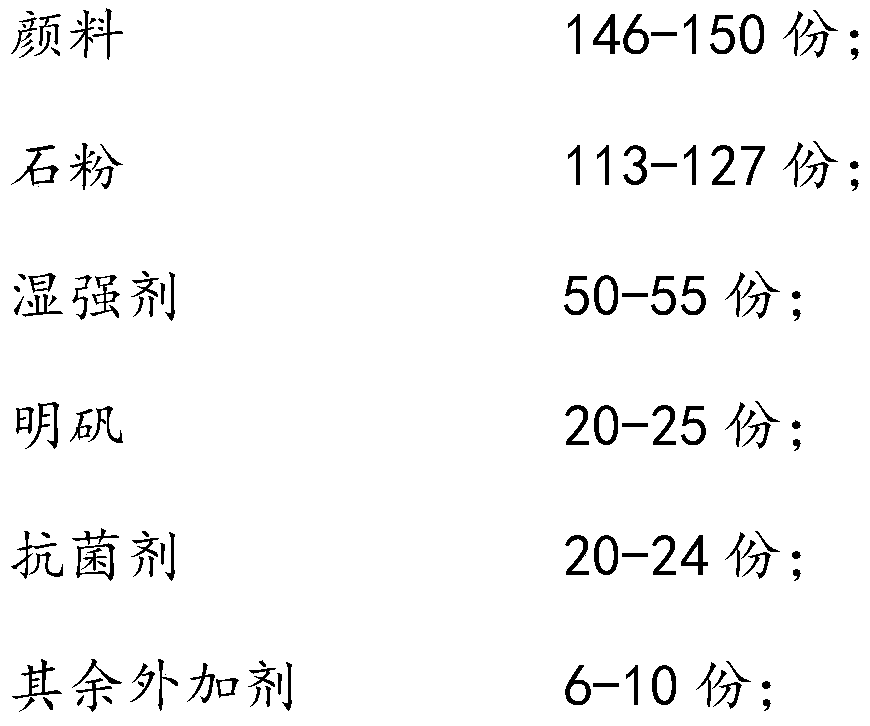

[0097] The difference between embodiments 10-13 and embodiment 1 is that the wet strength agent comprises the following raw materials in weight percentage:

[0098]

[0099] The difference between Embodiment 14-17 and Embodiment 1 is that the pigment comprises the following raw materials in weight percent:

[0100]

[0101] The difference between Embodiment 18-21 and Embodiment 1 is that the stone powder comprises the following raw materials in weight percent:

[0102]

[0103] The difference between embodiment 22-25 and embodiment 1 is that all the other admixtures include the following raw materials in weight percentage:

[0104]

[0105] The difference between Embodiment 26-29 and Embodiment 1 is that the mass concentration of softwood pulp is as shown in the following table:

[0106] Example Example 26 Example 27 Example 28 Example 29 Concentration / (%) 3 4 6 7

[0107] The difference between Examples 30-33 and Example 1 is that ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com