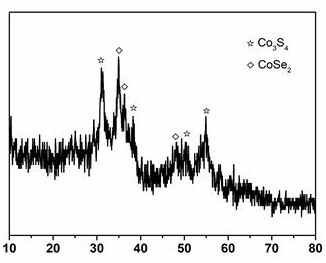

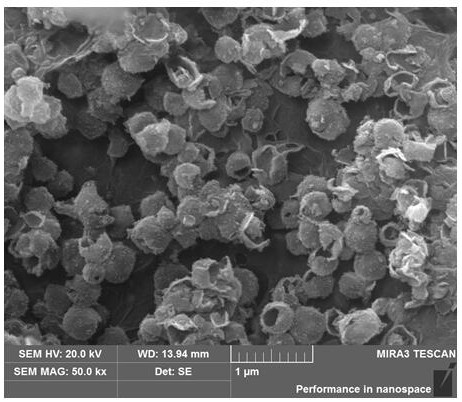

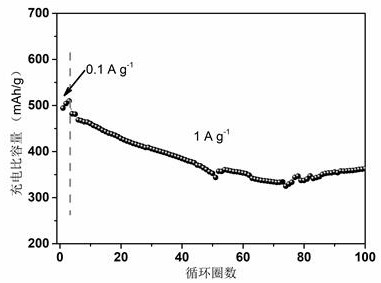

A kind of transition metal selenium sulfur complex and preparation method thereof

A transition metal and composite technology, applied in the direction of active material electrodes, structural parts, electrical components, etc., can solve the problems that the specific capacity and cycle performance cannot achieve the expected results, the selenium metal particles are easy to agglomerate, and the composite material has irregular morphology. , to achieve excellent cycle and rate performance, improve structural stability and conductivity, and excellent rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Preparation of the transition metal selenium sulfur complex of the present invention comprises the following steps:

[0041] (1) Weigh 1.1508 g of cobalt nitrate and dissolve it in 100 mL of methanol to form a cobalt nitrate solution; weigh 1.6231 g of 2-methylimidazole and dissolve it in 100 mL of methanol to form a 2-methylimidazole solution; Pour the 2-methylimidazole solution into the cobalt nitrate solution, and let it stand at room temperature for 20 hours, centrifuge, wash, and blow dry to obtain the metal organic framework;

[0042] (2) performing heat treatment on the metal organic framework to obtain the precursor, the heat treatment temperature is 600°C, the heat treatment time is 2 hours, and the heat treatment atmosphere is nitrogen atmosphere;

[0043](3) Weigh 0.5 mmol of selenium powder, disperse it in 15 mL of absolute ethanol at 0°C, add 1 mmol of sodium borohydride, and fully react until no bubbles are generated to obtain a selenium source solution; ...

Embodiment 2

[0048] Preparation of the transition metal sulfide of the present invention comprises the following steps:

[0049] (1) Weigh 1.1508 g of cobalt nitrate and dissolve it in 100 mL of methanol, weigh 1.6231 g of 2-methylimidazole and dissolve it in 100 mL of methanol, after fully dissolving, pour the 2-methylimidazole solution into the cobalt nitrate solution , and stood at room temperature for 20 hours, centrifuged, washed, and blast-dried to obtain a metal-organic framework;

[0050] (2) Perform heat treatment on the metal organic framework to obtain the precursor, the heat treatment temperature is 500°C, the heat treatment time is 2h, and the heat treatment atmosphere is argon and hydrogen (hydrogen content 5%) atmosphere;

[0051] (3) Weigh 0.5 mmol of selenium powder, disperse it in 15 mL of absolute ethanol at 0°C, add 1 mmol of sodium borohydride, and fully react until no bubbles are generated to obtain a selenium source solution;

[0052] (4) Dissolve 3.5 mmol of thioac...

Embodiment 3

[0055] Preparation of the transition metal sulfide of the present invention comprises the following steps:

[0056] (1) Weigh 0.4569 g of zinc nitrate and dissolve it in 100 mL of methanol, weigh 8.8274 g of 2-methylimidazole and dissolve it in 100 mL of methanol, after fully dissolving, pour the 2-methylimidazole solution into the cobalt nitrate solution , and stood at room temperature for 20 hours, centrifuged, washed, and blast-dried to obtain a metal-organic framework;

[0057] (2) Perform heat treatment on the metal organic framework to obtain the precursor, the heat treatment temperature is 600°C, the heat treatment time is 1h, and the heat treatment is an argon atmosphere;

[0058] (3) Weigh 0.5 mmol of selenium powder, disperse it in 15 mL of absolute ethanol at 0°C, add 1 mmol of sodium borohydride, and fully react until no bubbles are generated to obtain a selenium source solution;

[0059] (4) Dissolve 3.5 mmol of thioacetamide in 10 mL of ultrapure water as a sulf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com