Li2FeSiO4@mesoporous carbon lithium ion battery positive electrode material and preparation method thereof

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, positive electrodes, secondary batteries, etc., can solve the problems of large particles, poor carbon matrix dispersion, and low purity, and achieve low calcination temperature, short holding time, and increased The effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

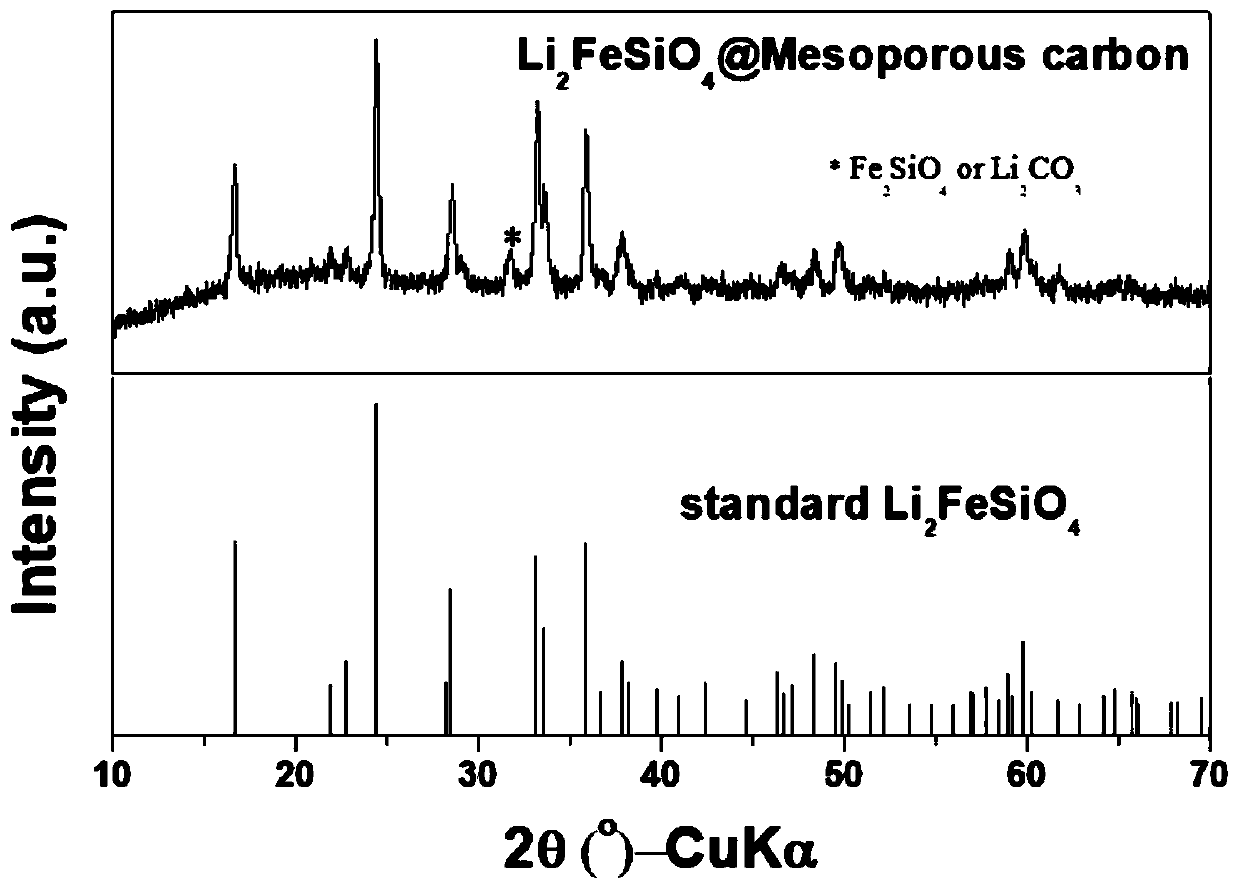

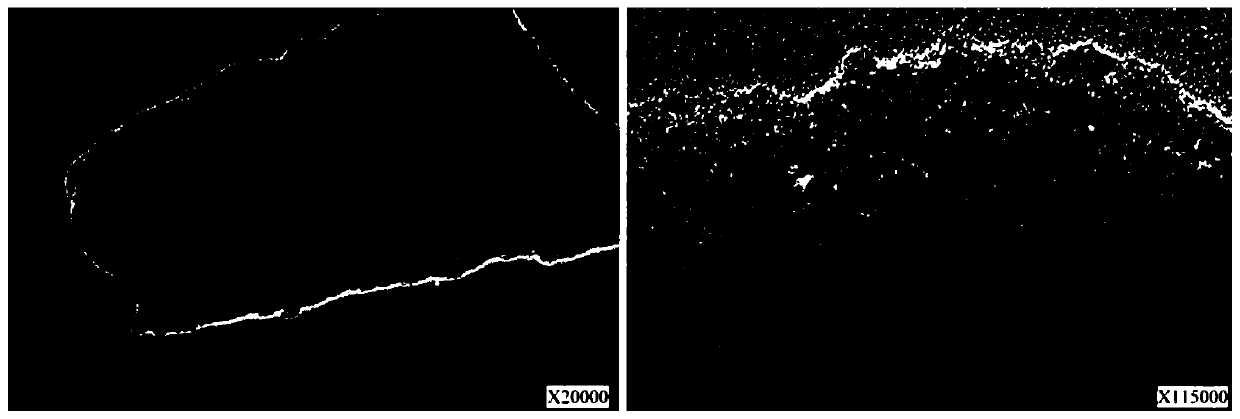

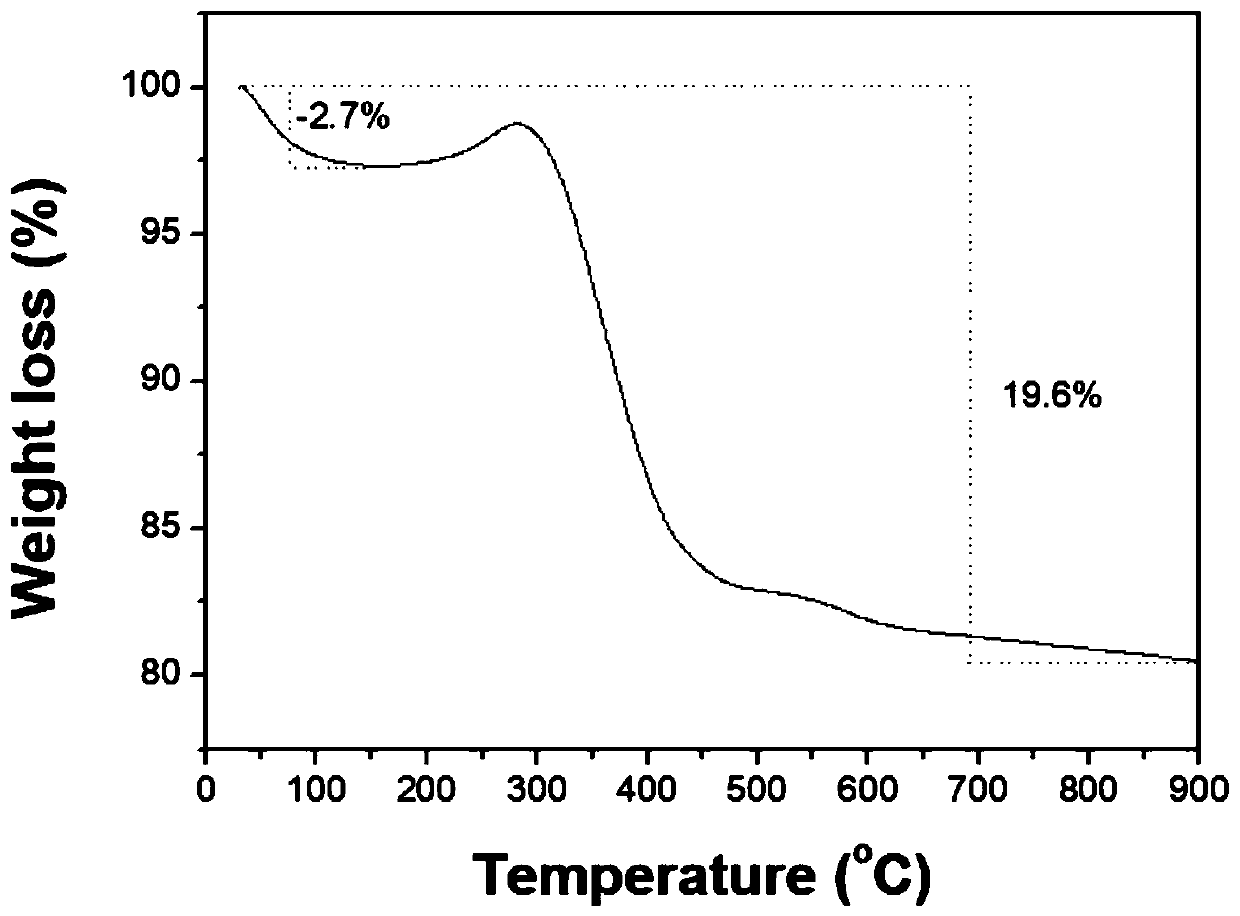

[0031] Dissolve 0.82g phloroglucinol, 0.61g glyoxylic acid monohydrate, and 1.61g F127 in 40mL ethanol, add 1.2784g lithium nitrate, 3.7451g ferric nitrate nonahydrate, 1.9312g ethyl orthosilicate, and stir to dissolve. The mixed solution was evenly transferred to 4 petri dishes. After evaporating the solvent at room temperature in the fume hood, it was dried at 80°C to obtain a xerogel. Rise to 800°C at 2°C / min and hold for 2 hours to obtain Li 2 FeSiO 4 @Mesoporous Carbon Composites.

Embodiment 2

[0033]Dissolve 0.82g phloroglucinol, 0.61g glyoxylic acid monohydrate, and 1.61g F68 in 50mL ethanol, add 1.8898g lithium acetate, 1.6130g ferrous acetate, and 1.4111g methyl orthosilicate successively, stir and dissolve, and obtain The mixed solution was evenly transferred to 5 petri dishes. After evaporating the solvent at room temperature in the fume hood, it was then dried at 60°C to obtain a xerogel. Rise to 700°C at 3°C / min and hold for 3h to obtain Li 2 FeSiO 4 @Mesoporous Carbon Composites.

Embodiment 3

[0035] Dissolve 1.8358g of phenol, 0.61g of glyoxylic acid monohydrate, and 1.61g of P123 in 60mL of ethanol, add 1.2784g of lithium nitrate, 3.7451g of ferric nitrate nonahydrate, and 1.9312g of ethyl orthosilicate in turn, stir and dissolve, and the resulting mixed solution Evenly transfer to 6 Petri dishes, evaporate the solvent at room temperature in the fume hood, and then dry at 70°C to obtain dry gels, and dry the obtained dry gels at 1°C / min up to 600°C and hold for 4 hours to obtain Li 2 FeSiO 4 @Mesoporous Carbon Composites.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com