Modified nano iron oxide particles and application thereof in anaerobic fermentation

A technology of nano-iron oxide and iron oxide particles, which is applied in the field of nano-materials, can solve the problems of low gas production rate and unsatisfactory effect, and achieve the effect of promoting methane production, promoting interaction, and promoting production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

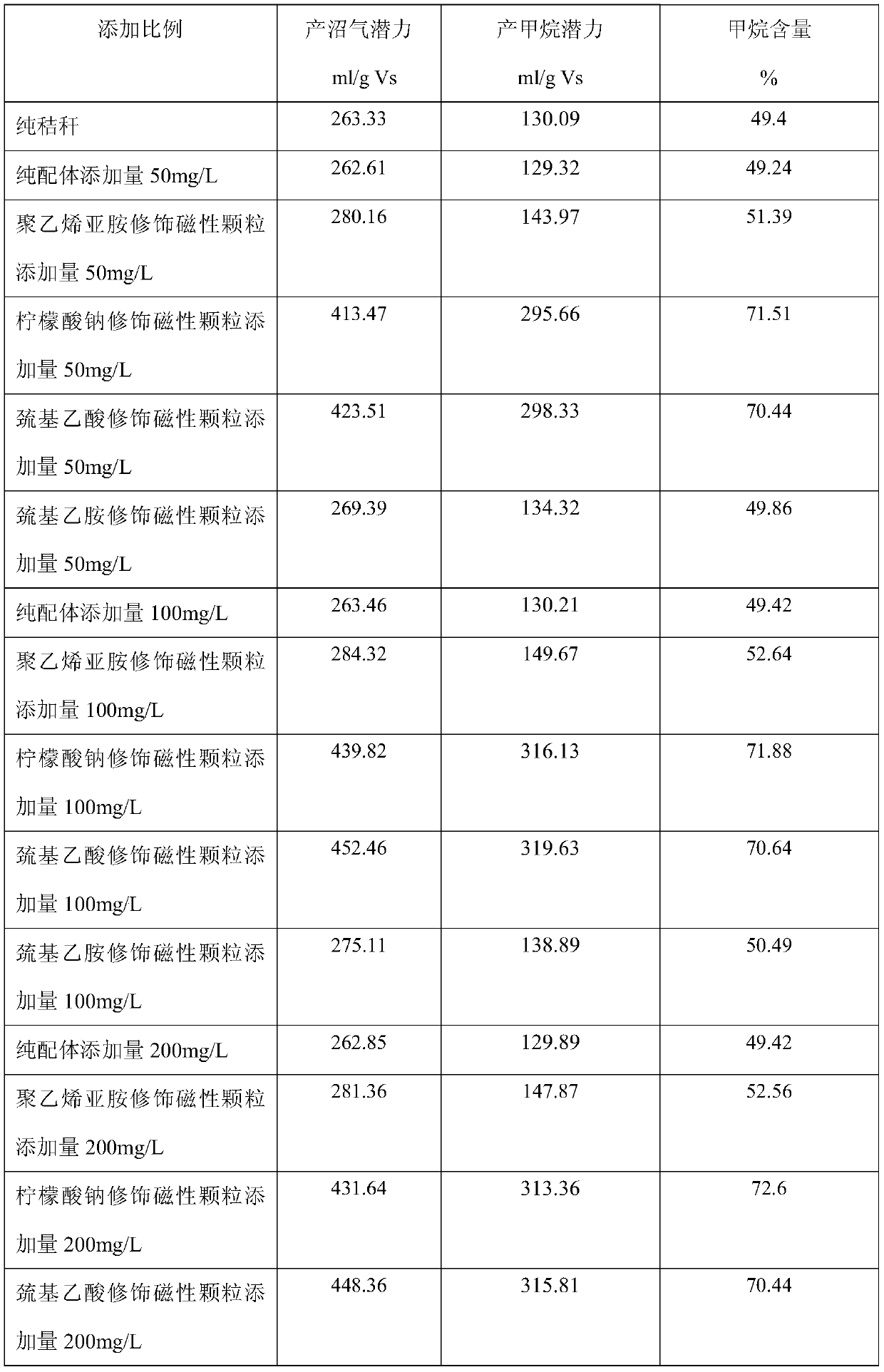

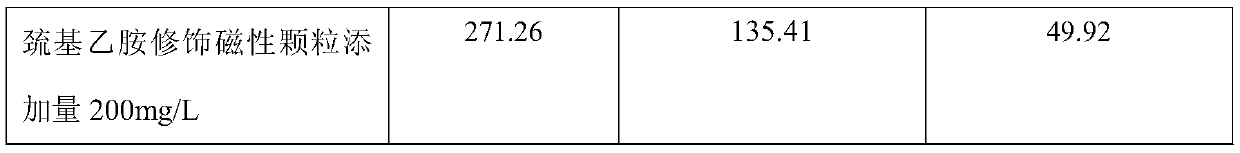

Examples

Embodiment 1

[0024] Embodiment 1 Preparation of modified nano-iron oxide particles

[0025] FeCl 3 and FeCl 2 Dissolve in a certain amount of distilled water at a molar ratio of 2:1 and heat to 60°C. Under the protection of argon, concentrated ammonia water was slowly added to make the pH of the solution 9 and kept for 2 h. After the reaction, the sample was washed three times with deionized water and ethanol to obtain bare-core magnetic nanoparticles.

[0026] Take a certain amount of nano-Fe 3 o 4 Dissolve the magnetic particles in 100ml of distilled water, and ultrasonically treat them for 15-30 minutes to completely disperse them. Then slowly add 50-70 mg of surface ligand molecule polyethyleneimine into the solution. After stirring for 24-48 hours, the ligand-modified Fe 3 o 4 The nanoparticles are separated from the solution, washed repeatedly with distilled water and methanol, and dried in vacuum to obtain the final magnetic nanoparticles.

Embodiment 2

[0027] The preparation of embodiment 2 modified nano-iron oxide particles

[0028] FeCl 3 and FeCl 2 Dissolve in a certain amount of distilled water at a molar ratio of 2:1 and heat to 60°C. Under the protection of argon, concentrated ammonia water was slowly added to make the pH of the solution 9 and kept for 2 h. After the reaction, the sample was washed three times with deionized water and ethanol to obtain bare-core magnetic nanoparticles.

[0029] Take a certain amount of nano-Fe 3 o 4 Dissolve the magnetic particles in 100ml of distilled water, and ultrasonically treat them for 15-30 minutes to completely disperse them. Then slowly add 60-80 mg of sodium citrate containing surface ligand molecules into the solution. After stirring for 24-36 hours, the ligand-modified Fe 3 o 4 The nanoparticles are separated from the solution, washed repeatedly with distilled water and methanol, and dried in vacuum to obtain the final magnetic nanoparticles.

Embodiment 3

[0030] Embodiment 3 Preparation of modified nano iron oxide particles

[0031] FeCl 3 and FeCl 2 Dissolve in a certain amount of distilled water at a molar ratio of 2:1 and heat to 60°C. Under the protection of argon, concentrated ammonia water was slowly added to make the pH of the solution 9 and kept for 2 h. After the reaction, the sample was washed three times with deionized water and ethanol to obtain bare-core magnetic nanoparticles.

[0032] Take a certain amount of nano-Fe 3 o 4 Dissolve the magnetic particles in 100ml of distilled water, and ultrasonically treat them for 15-25 minutes to completely disperse them. Then slowly add 65-85 mg of thioglycolic acid containing surface ligand molecules into the solution. After stirring for 12-24 hours, the ligand-modified Fe 3 o 4 The nanoparticles are separated from the solution, washed repeatedly with distilled water and methanol, and dried in vacuum to obtain the final magnetic nanoparticles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com