A method for preparing high-quality bio-oil from pig manure

A high-quality, bio-oil technology, applied in the field of pig manure treatment, achieves the effects of low energy consumption, reduced dependence, and strong industrial potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A method of preparing high quality biological oil as principles, including the following steps:

[0053] a, pretreatment: dry fresh pig manure to a water content of 10%, then pulverizing pig manure over 80 mesh sieve;

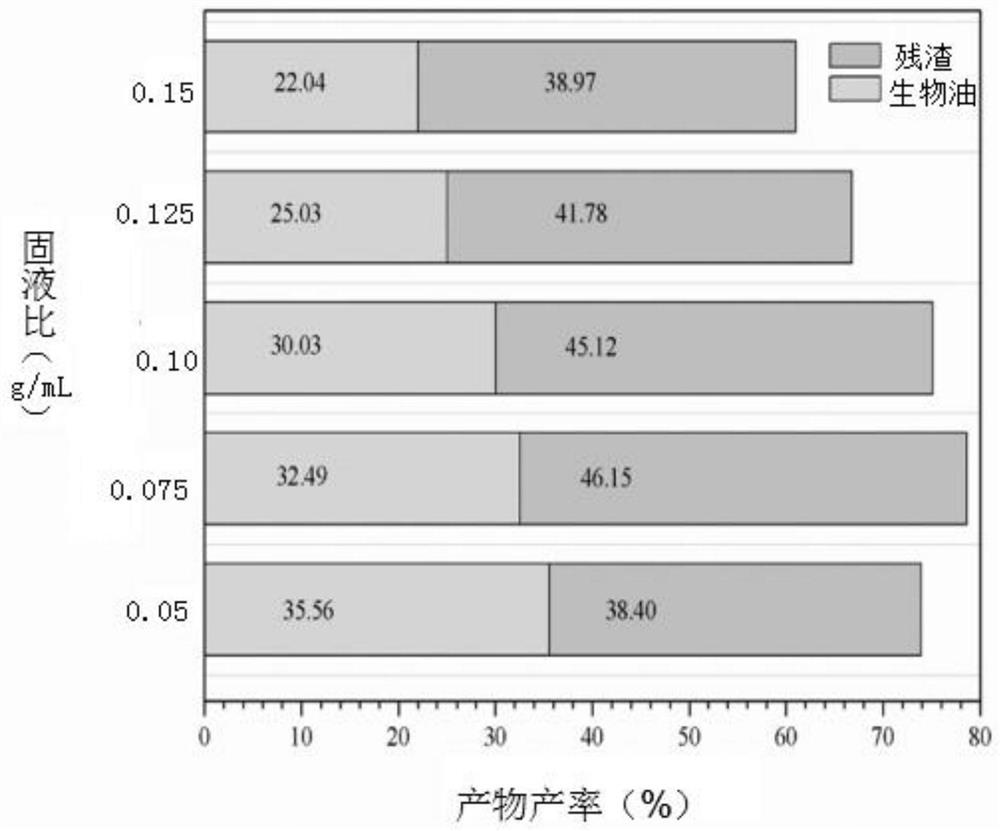

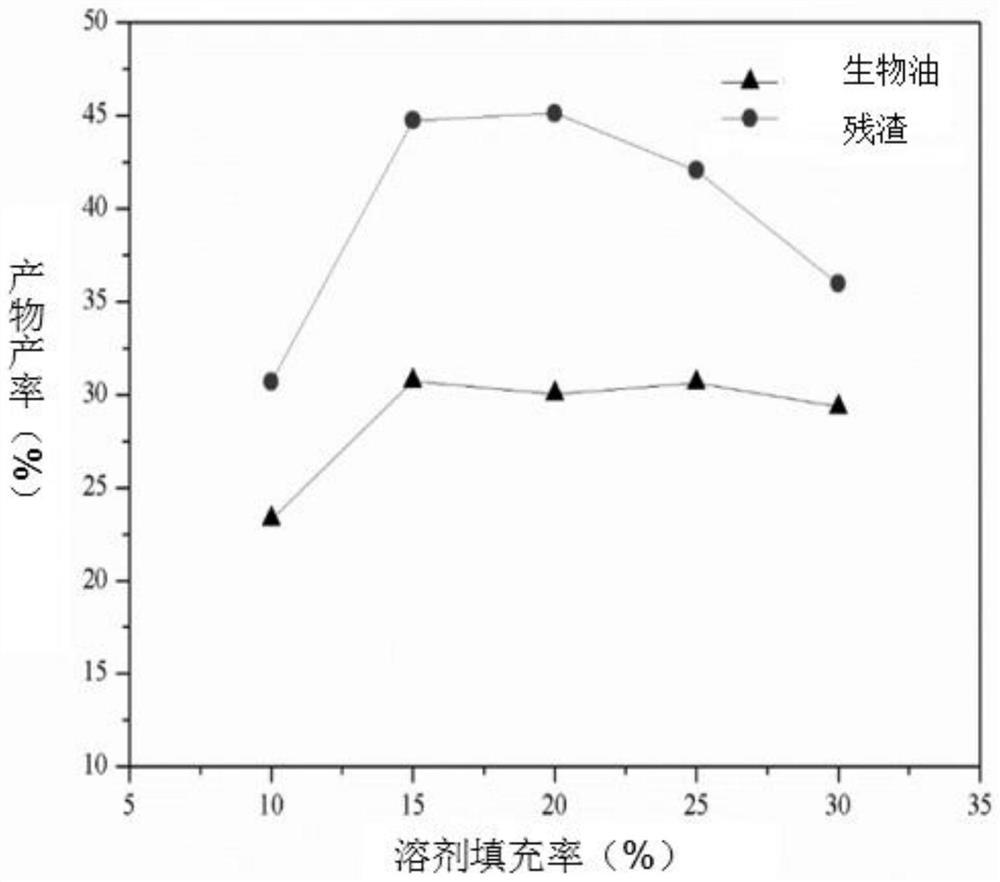

[0054] B, sub / ultra-critical liquefaction: the treatment after the treatment of pig manure and anhydrous ethanol are 0.1 g / ml of solid flow ratio, and the filler rate of solvent-free ethanol is 20% mixed into the reactor; sealed reactor, design The pressure is 12.5 MPa, the heating voltage is 250V, and the liquidation temperature is 220 ° C; the reaction kettle is heated, and the temperature is allowed to stop 40 min, and the heating is stopped after the reaction is completed. When the reaction kettle temperature is about 100 ° C. Condensate cools the reaction kettle to room temperature;

[0055] C. Solid-Liquid Separation: Directly discharged directly from the gas phase product of the reaction without further analysis, opening the reactor cover, takes t...

Embodiment 2

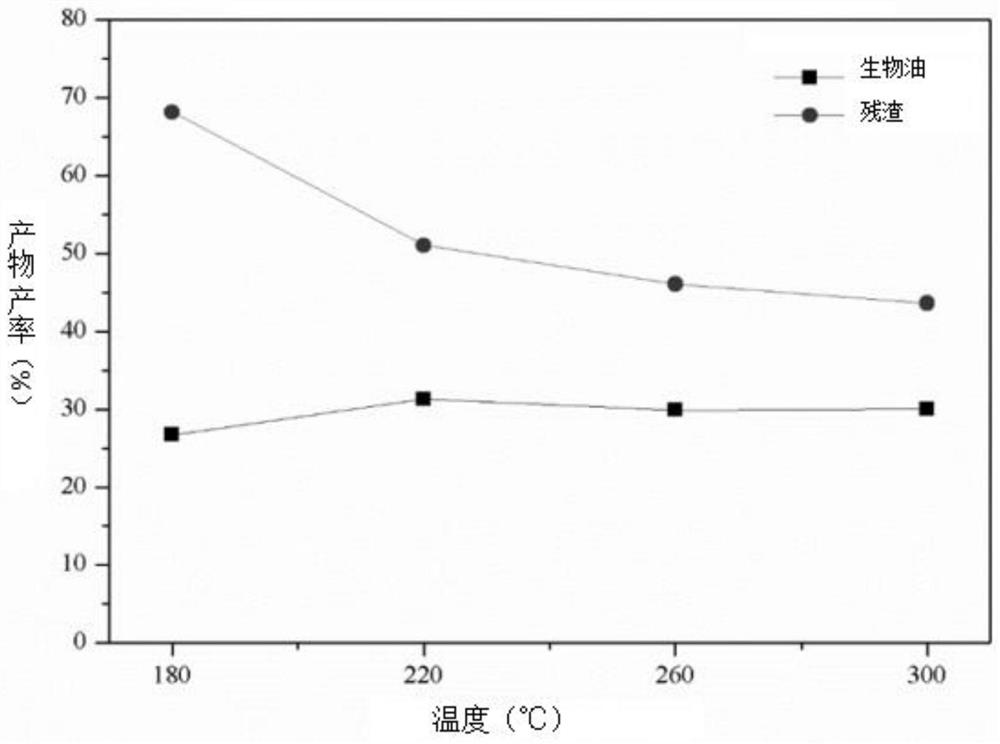

[0058] The difference from the first embodiment is that the liquefied temperature is 260 ° C, and the obtained bio-oil sample is S2.

Embodiment 3

[0060] The difference between the present embodiment and the first embodiment is that the liquefied temperature is 300 ° C and the resulting bio-oil sample is S3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com