High-saturation-magnetic ultra-fine grain nano two-phase permanent magnet material and preparation method thereof

A technology of permanent magnetic materials and ultra-fine crystals, which is applied in the direction of magnetic materials, inorganic materials, magnetic objects, etc., can solve the problem of limiting the exchange coupling effect and magnetic energy product of nano-two-phase materials, difficulty in reaching ultra-fine nanoscale, complicated procedures, etc. problem, to achieve the effect of avoiding the growth and coarsening of soft magnetic particles, avoiding high temperature treatment process, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] Another aspect of the embodiments of the present invention provides a method for preparing a high-saturated ultrafine-grained nano-dual-phase permanent magnet material, comprising:

[0030] The hard magnetic particles are surface activated with an acidic substance to obtain activated hard magnetic particles;

[0031] In a protective atmosphere, at a temperature of 20-70 °C, the activated hard magnetic particles are uniformly dispersed in the mixture of oil phase solvent and co-surfactant to form a dispersion of activated hard magnetic particles, and then slowly Add soft magnetic precursor material, and add alkaline agent and reducing agent at the same time, mix and react to form a water-in-oil microemulsion with ultra-fine bubbles, so that soft magnetic particles self-assemble on the surface of activated hard magnetic particles to obtain high saturation magnetic ultrafine Crystal nano duplex permanent magnet material.

[0032] As one of the preferred solutions, the pre...

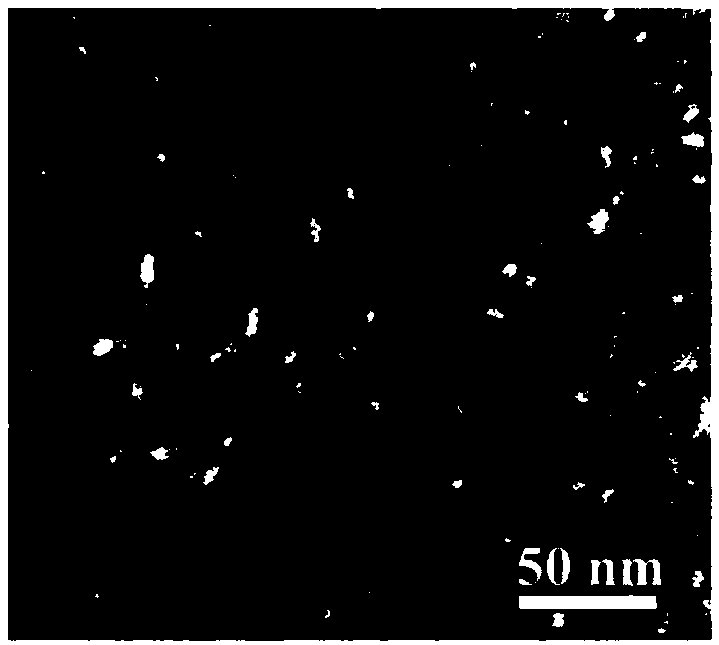

Embodiment 1

[0069] (1) Under the protection of high-purity Ar gas, 0.12g of SmCo with a saturation magnetization of 90emu / g 5 The magnetic powder and 60 ml of anhydrous ethanol were put into a four-necked flask, and the hard magnetic powder was uniformly dispersed by ultrasonic and mechanical stirring in a 60°C water bath, and then 0.5 ml of dilute hydrochloric acid was added to activate the hard magnetic powder. After activating for 10 minutes, the acid solution was removed to obtain Activated hard magnetic particles.

[0070] (2) Under the protection of high-purity Ar gas, select oleic acid as the oil phase solvent and absolute ethanol as the co-surfactant, and use ultrasonic and mechanical stirring to remove the activated SmCo 5 The hard magnetic powder is uniformly dispersed in the mixed solution of oil phase solvent and co-surfactant with a ratio of 1:60. FeCl 2 ·4H 2 O and CoCl 2 ·6H 2 O soft magnetic raw material, NaOH alkaline agent, and hydrazine hydrate reducing agent with a...

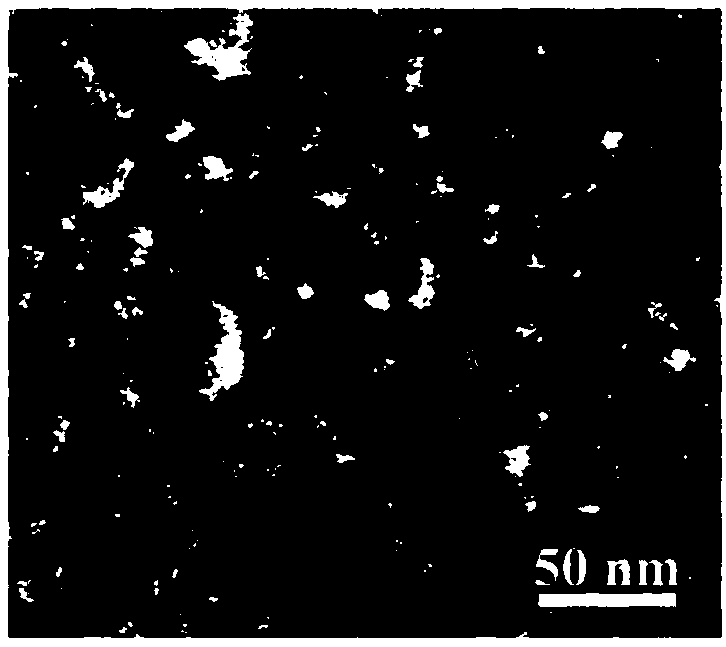

Embodiment 2

[0074] In the present embodiment, the raw materials are exactly the same as the raw materials in Example 1, as follows:

[0075] (1) identical with the step (1) of embodiment 1;

[0076] (2) It is basically the same as step (2) in Example 1, except that when the soft magnetic phase is assembled by the mixed reaction, the ratio of the oil phase solvent to the cosurfactant is 1:30.

[0077] This example obtains SmCo 5 / Fe-Co nano-dual-phase composite permanent magnetic particles, the size and magnetic properties of the soft magnetic particles are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com