High-temperature cooking-resistant easy-peeling high-barrier nylon composite film and preparation method thereof

A high-barrier, high-temperature-resistant technology, applied in the field of high-barrier nylon composite film and its preparation, can solve the problems of inconvenient operation, the need to improve the oxygen barrier performance, and the high cost of the composite process, and achieve the effect of zero emission reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

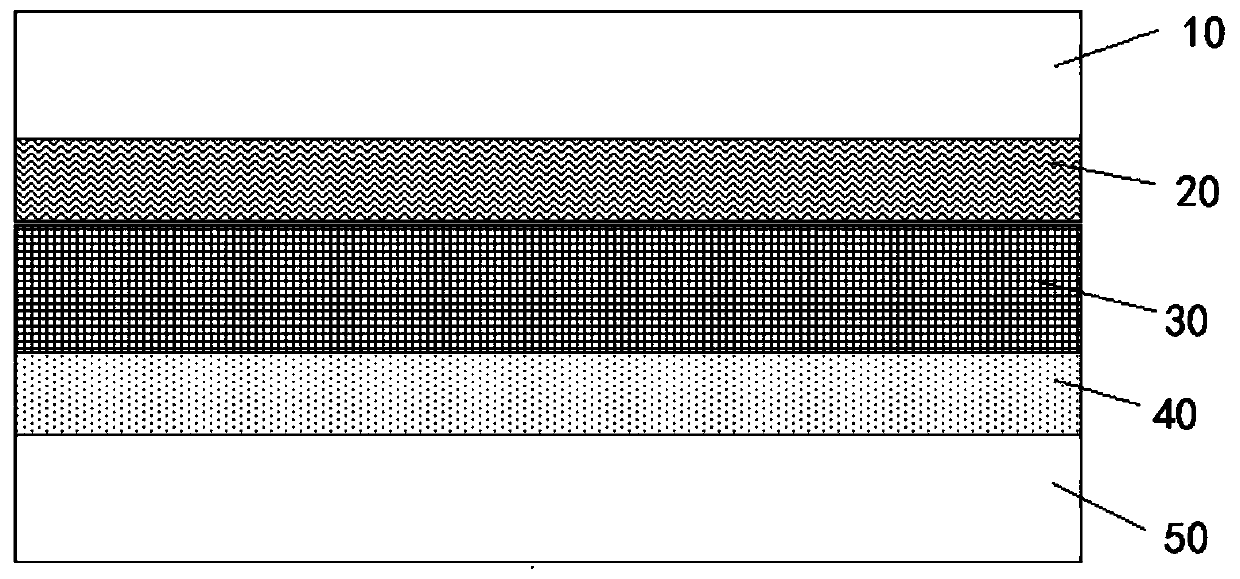

[0040] The composite film sequentially includes a modified polypropylene layer 10, an adhesive layer 20, a first barrier layer 30, a second barrier layer 40 and a nylon layer 50 from top to bottom; the total thickness is 45 μm.

[0041] The composition of the modified polypropylene layer is 78% high temperature resistant homopolypropylene, 1% ethylene acrylic acid copolymer, 20% styrene block copolymer, 0.5% poly-4-methyl-1-pentene, 0.5% anti-blocking agent; the thickness is 10μm.

[0042] The adhesive layer is made of maleic anhydride-modified random polypropylene; the thickness is 5 μm.

[0043] The first barrier layer consists of 95% copolymerized nylon 6 / 66 and 5% modified polyvinyl alcohol resin composition; the thickness is 10 μm; wherein, the modified polyvinyl alcohol resin composition is: using vinyl modified polyethylene Alcohol and nano magnesium oxide for modification.

[0044] The composition of the second barrier layer is 95% EVOH and 5% PA6I / 6T; the thickness ...

Embodiment 2

[0048] The composite film sequentially includes a modified polypropylene layer 10, an adhesive layer 20, a first barrier layer 30, a second barrier layer 40 and a nylon layer 50 from top to bottom; the total thickness is 35 μm.

[0049] The composition of the modified polypropylene layer is 73% high temperature resistant homopolypropylene, 10% ethylene acrylic acid copolymer, 15% styrene block copolymer, 1% 4-methyl-1-pentene random Copolymer, 1% slip agent; thickness 6 μm.

[0050] The adhesive layer is made of maleic anhydride-modified ethylene-acrylate; the thickness is 5 μm.

[0051] The composition of the first barrier layer is 90% copolymerized nylon 66 / 6 and 10% modified polyvinyl alcohol resin composition; the thickness is 10 μm; wherein, the modified polyvinyl alcohol resin composition is: using carboxy-modified polyvinyl alcohol and Nano-magnesium oxide was modified.

[0052] The composition of the second barrier layer is 90% EVOH and 10% PA6I / 6T; the thickness is ...

Embodiment 3

[0056] The composite film sequentially includes a modified polypropylene layer 10, an adhesive layer 20, a first barrier layer 30, a second barrier layer 40 and a nylon layer 50 from top to bottom; the total thickness is 20 μm.

[0057] The composition of the modified polypropylene layer is 70.5% high temperature resistant homopolypropylene, 25% ethylene acrylic acid copolymer, 1% styrene block copolymer, 2% 4-methyl-1-pentene and α- Olefin copolymer, 1% slip agent, 0.5% antistatic agent; thickness 4μm.

[0058] The adhesive layer is made of maleic anhydride-modified ethylene vinyl acetate; the thickness is 2 μm.

[0059] The composition of the first barrier layer is a modified polyvinyl alcohol resin composition of 75% nylon 66 / 610 and 25%; the thickness is 5 μm; wherein, the modified polyvinyl alcohol resin composition is: glycidyl methacrylate Modified polyvinyl alcohol and nano magnesium oxide are used for modification.

[0060] The composition of the second barrier laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com