Solid-state fluorescent carbon quantum dot with variable luminous color and preparation method thereof

A technology of carbon quantum dots and luminescent color, applied in the field of fluorescent luminescent materials, which can solve the problems of few reports and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Add 0.4054 g of phloroglucinol dihydrate and 2.4024 g of urea into 10 mL of distilled water, and sonicate for 3 min to obtain a uniformly dispersed reaction solution.

[0041] The reaction solution was placed in a 100 mL glass beaker, and reacted in a 288W microwave oven for 15 min. After the reaction is finished, cool to room temperature, take out the reaction product, and grind to obtain a crude product of carbon quantum dot powder.

[0042] Transfer the crude product of carbon quantum dot powder to a centrifuge tube, centrifuge with distilled water as the eluent, wash off the reaction by-products, collect the precipitate at the bottom of the centrifuge tube, and dry it in a vacuum oven at 80°C for 2 hours to obtain green purified carbon Quantum dot solid powder.

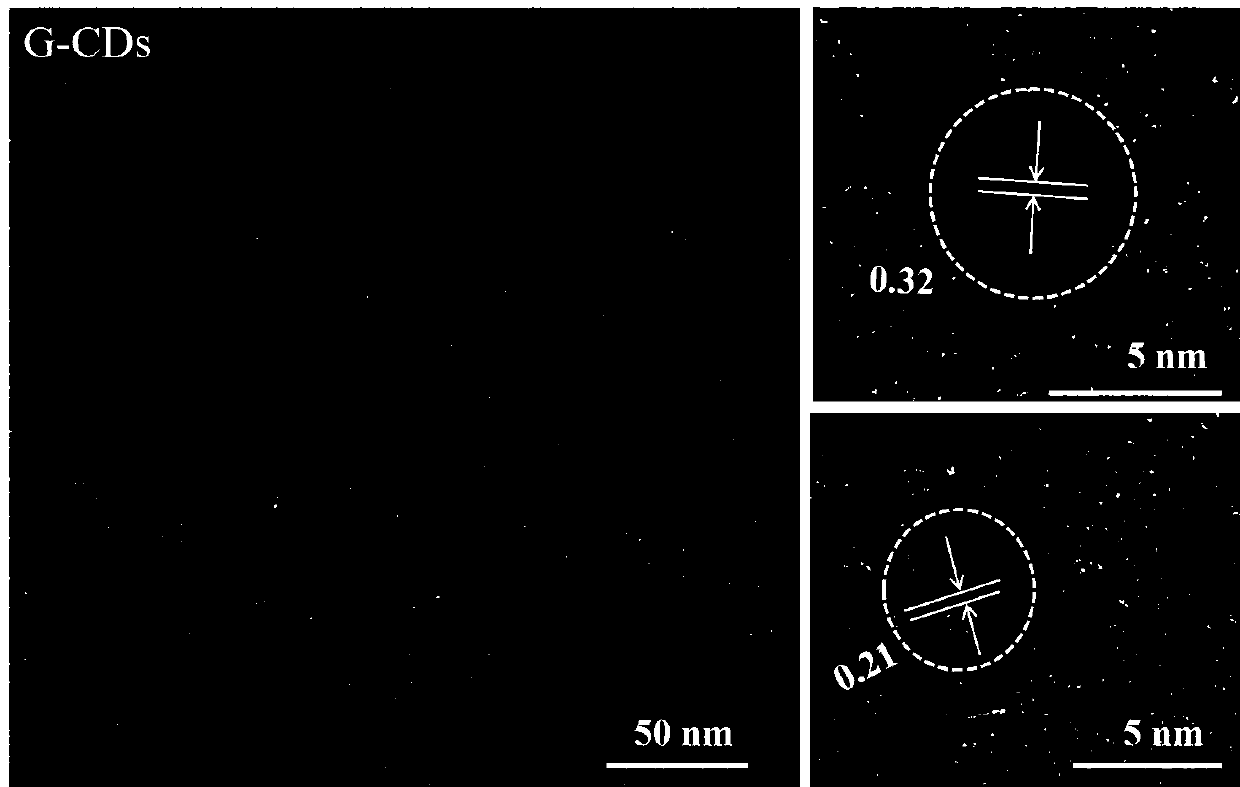

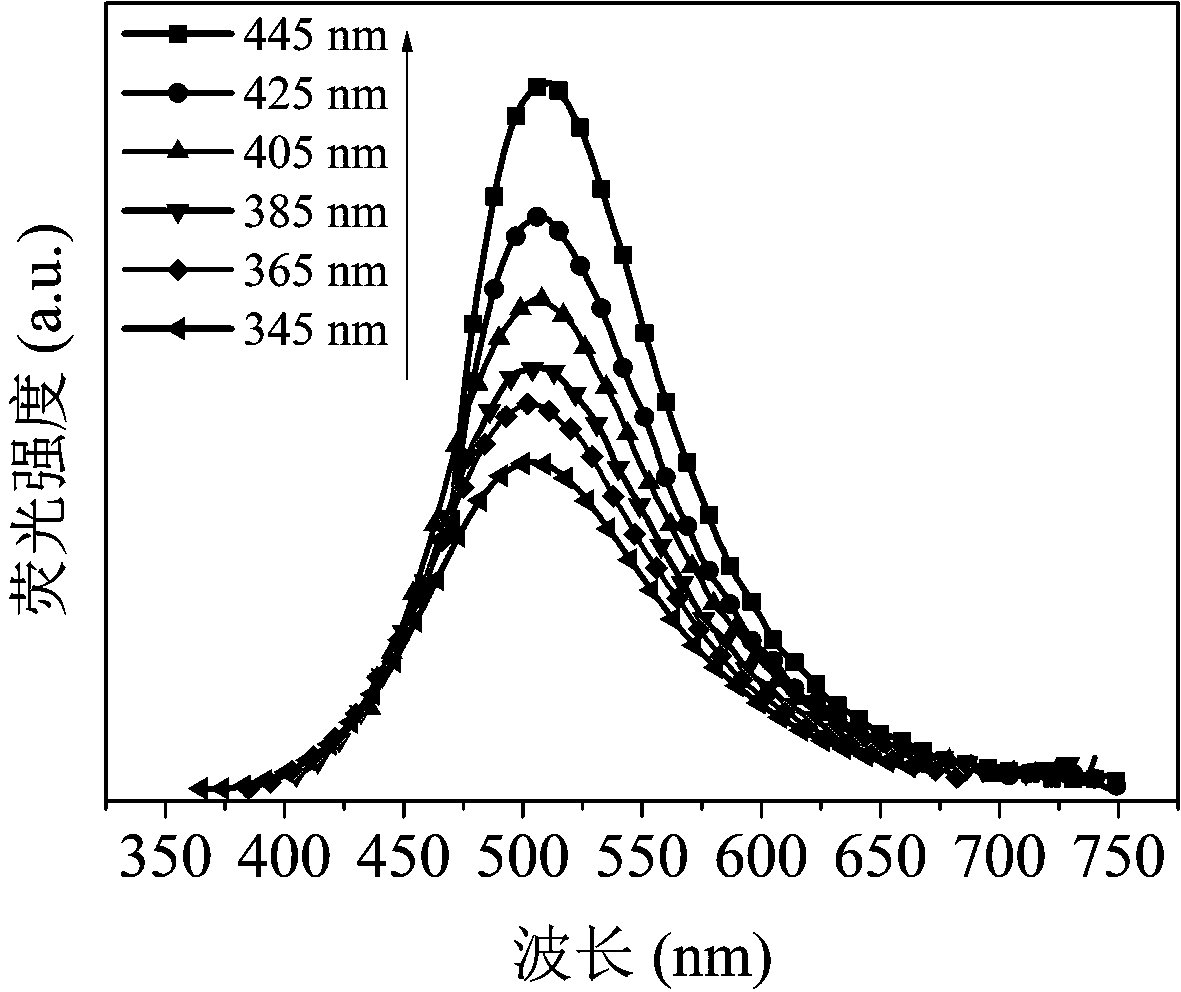

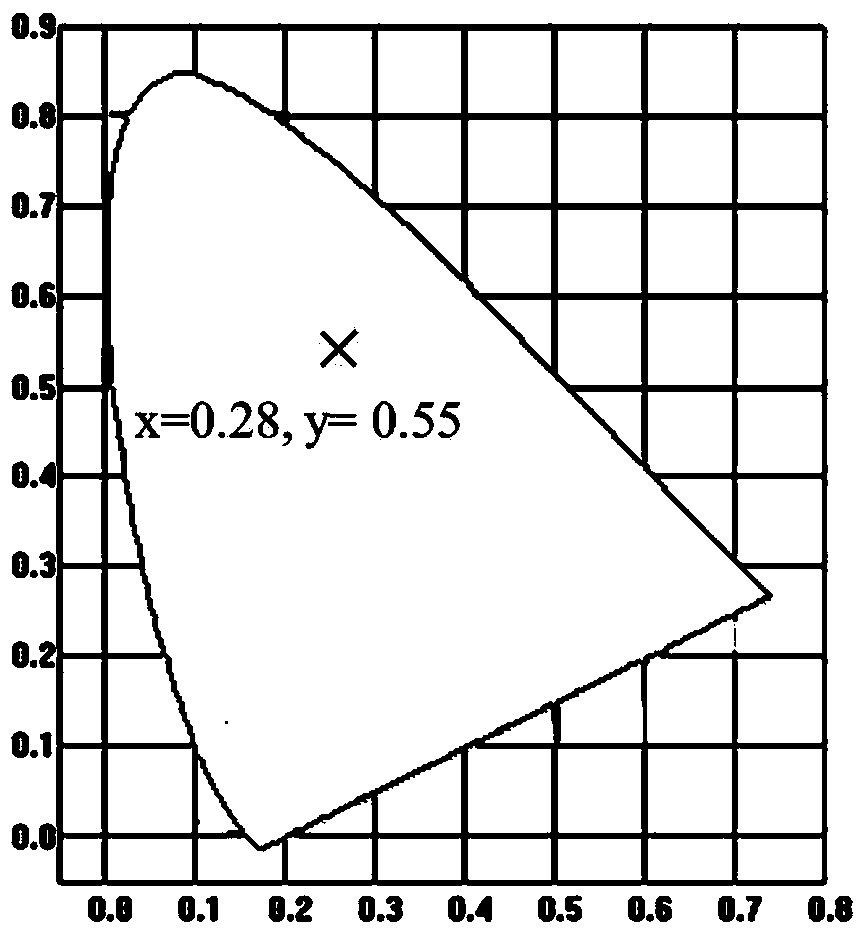

[0043] figure 1 It is the TEM photo of the prepared green fluorescent carbon quantum dots. It can be seen from the figure that the green fluorescent carbon quantum dots are uniformly dispersed, the parti...

Embodiment 2

[0047] Add 1.6214 g of phloroglucinol dihydrate and 1.2012 g of urea into 10 mL of distilled water, and sonicate for 3 min to obtain a uniformly dispersed reaction solution.

[0048] The reaction solution was placed in a 100 mL glass beaker, and reacted in a 288W microwave oven for 15 min. After the reaction is finished, cool to room temperature, take out the reaction product, and grind to obtain a crude product of carbon quantum dot powder.

[0049] Transfer the crude product of carbon quantum dot powder to a centrifuge tube, centrifuge with distilled water as the eluent, wash off the reaction by-products, collect the precipitate at the bottom of the centrifuge tube, and dry it in a vacuum oven at 80°C for 2 hours to obtain yellow purified carbon Quantum dot solid powder.

[0050] Figure 4 It is the TEM photo of the prepared yellow fluorescent carbon quantum dots. It can be seen from the figure that the yellow fluorescent carbon quantum dots are uniformly dispersed, the par...

Embodiment 3

[0054] Add 1.6214 g of phloroglucinol dihydrate and 0.3003 g of urea into 10 mL of distilled water, and sonicate for 3 min to obtain a uniformly dispersed reaction solution.

[0055] The reaction solution was placed in a 100 mL glass beaker, and reacted in a 288W microwave oven for 15 min. After the reaction is finished, cool to room temperature, take out the reaction product, and grind to obtain a crude product of carbon quantum dot powder.

[0056] Disperse the crude product of carbon quantum dot powder in ethanol to form a uniform dispersion, and filter it with a 0.22 μm polyvinylidene fluoride microporous membrane to obtain a purified carbon quantum dot ethanol dispersion, which is placed in a spinner bottle of a rotary evaporator , dried at 45° C. for 20 minutes to evaporate ethanol to obtain carbon quantum dot solids.

[0057] Transfer the above-mentioned carbon quantum dot solid to a centrifuge tube, and centrifuge with a mixed solution of petroleum ether and absolute ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com