Pomelo peel porous carbon material and preparation methodand application thereof

A porous carbon material, grapefruit peel technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of limited application of supercapacitors, complex production process, long production cycle, etc., to solve the problem of low recycling rate , the raw materials are easy to obtain, the production method is simple and effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] To prepare grapefruit peel charcoal:

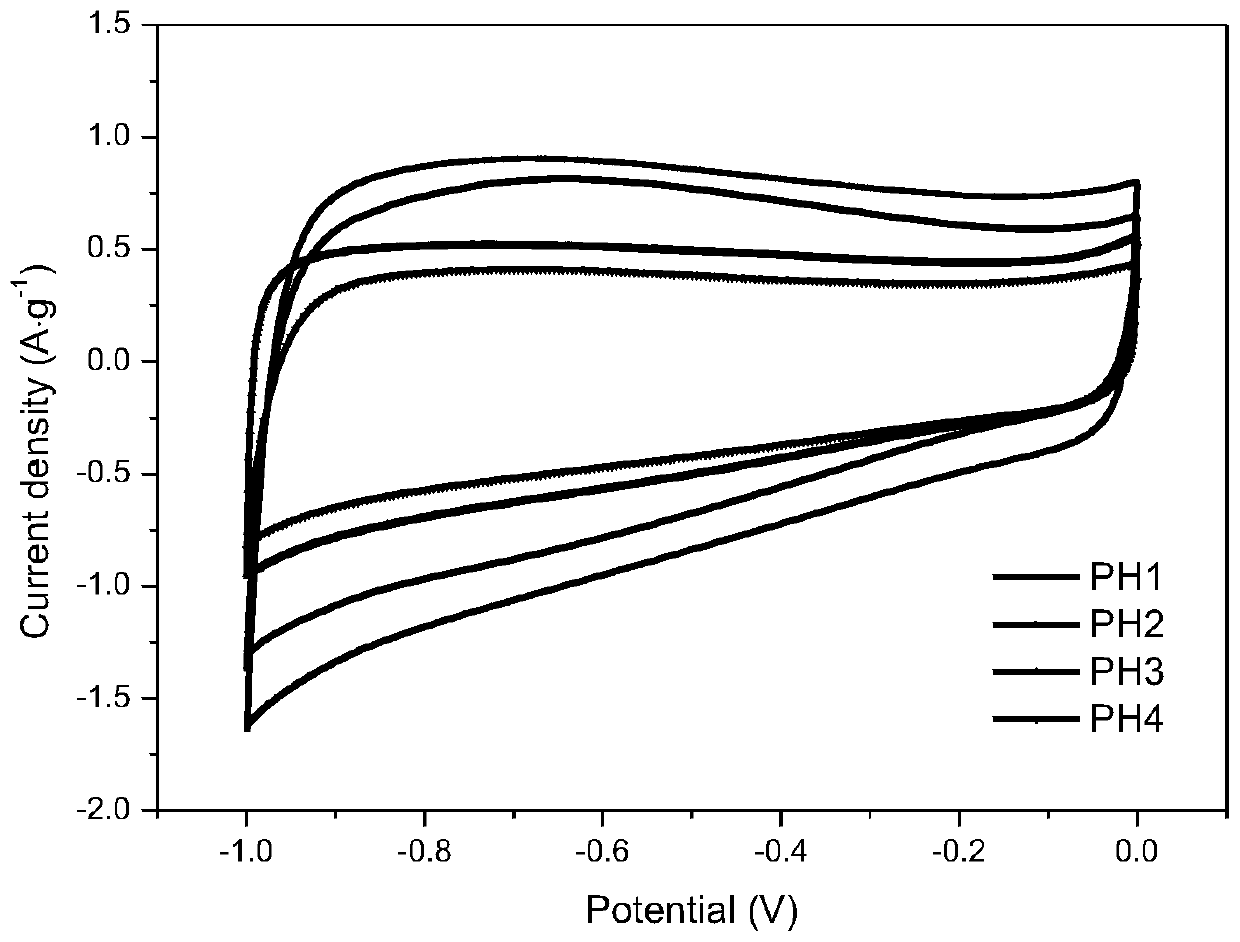

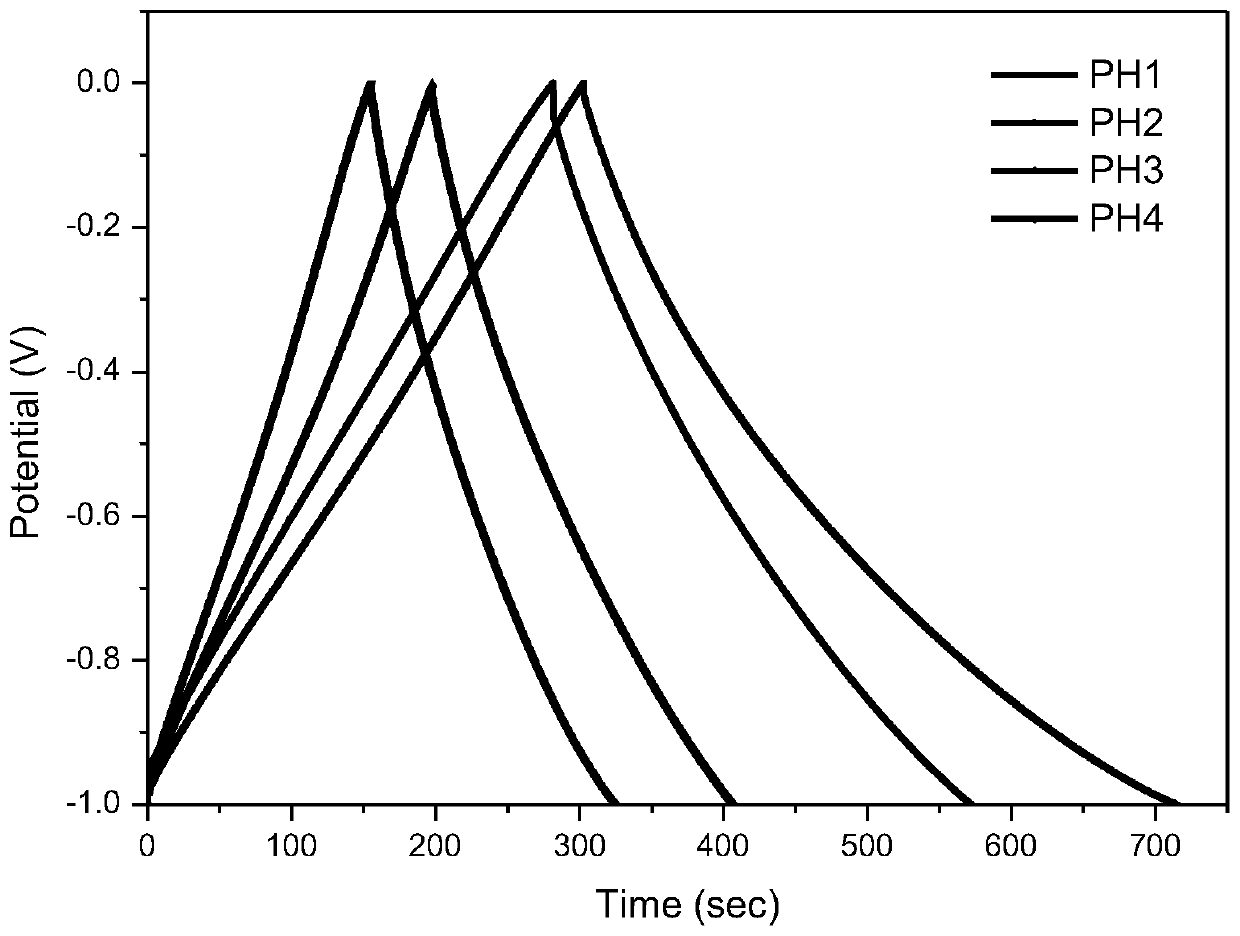

[0037] Put 5g of pomelo peel in a porcelain boat, put nitrogen in the tube furnace for 30min, then raise the temperature to 450℃ at a rate of 2℃ / min under the protection of nitrogen, carbonize for 2 hours and then cool naturally to obtain carbonization grapefruit peel. Mix the carbonized pomelo peel and KOH in a certain mass ratio (m (carbonized pomelo peel): m(KOH)=1:1, 1:2, 1:3, 1:4) and name them PH1, PH2 , PH3, PH4. Then each sample was ground in an agate mortar and then placed in a tube furnace and fed with nitrogen for 30 minutes. Under the protection of nitrogen, the temperature was raised to 800 degrees Celsius at a rate of 2 degrees Celsius / min, activated for 2 hours and then cooled naturally. . Add 6M KOH to the activated material and adjust the pH to about 10 (because the alkali will corrode the porcelain boat, so add the lye to dissolve the corroded porcelain boat inner wall material mixed in the material), and put i...

Embodiment 2

[0047] Electrode fabrication and assembly:

[0048] Firstly, nickel foam is washed with deionized water and ethanol ultrasonically, dried and weighed, then the prepared sample is mixed with polyvinylidene fluoride and acetylene black at a mass ratio of 0.85:0.05:0.15, and N-methylpyrrolidone is added After mixing, apply it on 2×1cm foamed nickel, then place it in a vacuum oven and dry it at 80°C for about 6 hours, press it on a desktop electric tablet machine with a pressure of 10MPa, and weigh the mass of foamed nickel again, twice 85% of the mass difference is the active substance mass. A three-electrode system is composed of nickel foam coated with active material as the working electrode, nickel foam as the counter electrode, and HgO / Hg electrode as the reference electrode, immersed in 6MKOH for 3 hours, and 10min N into the electrolytic cell before the test. 2 Exhaust O 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com