Polycarboxylate superplasticizer and rapid synthesis method thereof at normal temperature

A technology of water reducing agent and polycarboxylic acid, which is applied in the field of polycarboxylic acid water reducing agent and its rapid synthesis at room temperature, which can solve the problems of high energy consumption and long reaction time, and achieve faster speed, excellent water reduction and slump retention performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Prepare raw materials: 100 parts of GPEG polyether macromonomer, 0.5 part of oxidizing agent (hydrogen peroxide), 0.58 part of metal accelerator (FeSO4), 0.7 part of chain transfer agent (mercaptopropionic acid), unsaturated carboxylic acid small monomer (acrylic acid) 8 parts, 0.1 parts of reducing agent (E51).

[0026] Synthetic steps:

[0027] (1) Add 100 parts of GPEG polyether macromonomer into 67 parts of tap water to dissolve as the bottom liquid, stir and dissolve into a uniform and transparent solution, then add 0.6 parts of hydrogen peroxide with a mass fraction of 25-30% in the bottom liquid , the preferred mass fraction is 27.5% hydrogen peroxide and 0.58 parts mass fraction is 0.5-1% FeSO4 solution.

[0028] (2) Dissolve 8 parts of acrylic acid and 0.7 parts of mercaptopropionic acid in 10-12 parts of tap water to make dropwise solution A, and dissolve 0.1 part of E51 in 20-22 parts of tap water to make dropwise solution B for later use.

[0029] (3) Add ...

Embodiment 2

[0032] Prepare raw materials: 95 parts of GPEG polyether macromer, 0.58 part of oxidant (hydrogen peroxide), 0.5 part of metal accelerator (FeSO4), 0.4 part of chain transfer agent (mercaptopropionic acid), unsaturated carboxylic acid small monomer (acrylic acid) 9 parts, 0.09 parts of reducing agent (E51).

[0033] The synthesis steps are consistent with Example 1.

Embodiment 3

[0035] Prepare raw materials: 120 parts of GPEG polyether macromonomer, 0.7 part of oxidant (hydrogen peroxide), 0.7 part of metal accelerator (FeSO4), 0.8 part of chain transfer agent (mercaptopropionic acid), unsaturated carboxylic acid small monomer (acrylic acid) 15 parts, 0.15 parts of reducing agent (E51).

[0036] The synthesis steps are consistent with Example 1.

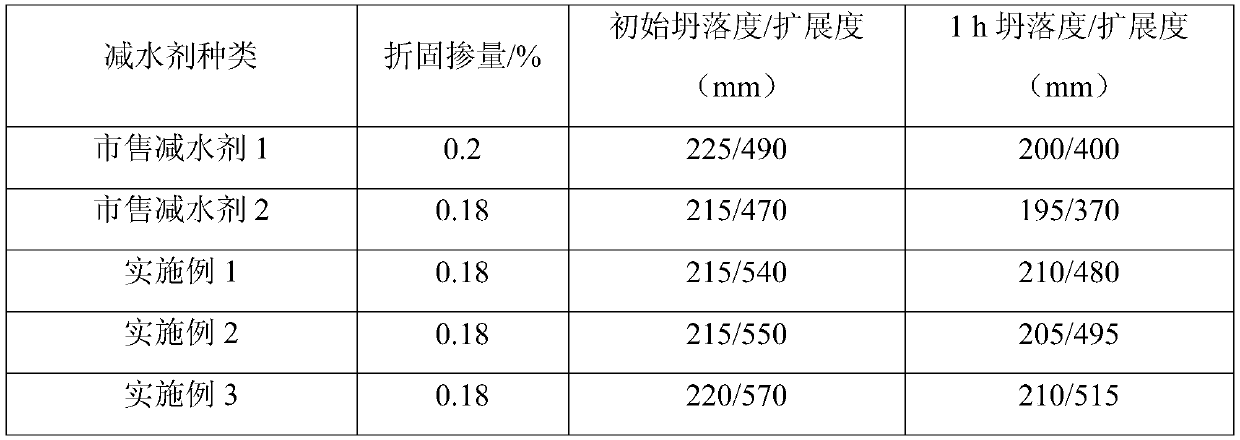

[0037] The samples synthesized in Examples 1-3 were compared with commercially available common polycarboxylate water reducers for concrete performance tests. Conch 42.5 cement is used; Class II fly ash; sand: machine-made sand, fineness modulus 2.60; crushed stone: particle size 5-30mm; concrete mix ratio is shown in Table 1.

[0038] Table 1: Concrete test mix ratio kg / m3

[0039] cement coal ash sand gravel water 280 90 902 977 160

[0040] According to GB-8077-2012 "Concrete Admixture Homogeneity Test Method", under the same test conditions, the initial slump / expansion of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com